2-2-5. Characteristics of Brushless DC Motors

Myriad Advantages

The biggest feature of brushless DC motors is that they are maintenance-free. There are a number of differences from DC motors.

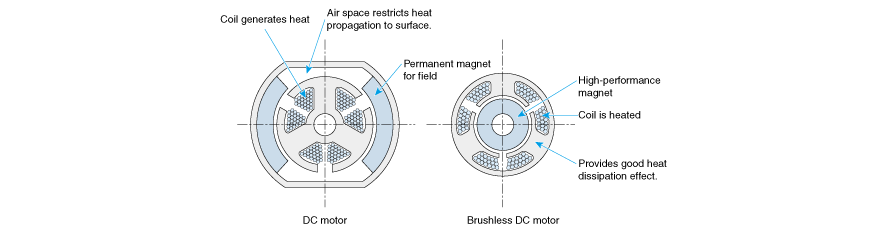

One of these differences is their small size. As shown in Fig. 2.29, a high-performance brushless DC motor accommodates high-performance magnets in a space smaller than that for the rotor of conventional DC motors.

Thanks to this space efficiency, the rotor has no magnets, allowing the corresponding space to be downsized.

A higher magnetic flux density provides higher motor efficiency and suppresses heat generation.

Among all the motor parts, the coil generates the greatest amount of heat. And since the coil of a DC motor is located inside the motor, it is enveloped by air in the motor, which prevents heat in the coil from dissipating. In comparison, since the coil of a brushless motor is positioned on the stator side, the motor's heat radiation performance is enhanced.

The decisive advantage of brushless motors is their high degree of freedom of design.

For instance, you can design a flat rotor, place the rotor in the outer part of the motor, or choose an elongated shape depending on how the motor is to be used.

Minimal Disadvantages

Coils of DC motors are circularly connected to switch the coil current sequentially as the motor rotates, suppressing torque non-uniformity.

It is possible to make a brushless DC motor rotate smoothly if the number of coils is increased to that used with a DC motor. In this case, the current flowing through individual coils must be switched using semiconductor devices.

However, since such an approach is unviable from a cost perspective, the coils of most brushless DC motors are divided into three groups in order to reduce the number of semiconductor devices.

However, we must come up with a devisal different from that for DC motors to reduce torque variations due to the rotational position of a motor that has only three coils.

If you rotate the motor shaft with your fingers, you will feel non-uniformity of torque (cogging) due to the attractive force generated between the rotor magnet and stator teeth.

Reducing cogging of a motor requires meticulous analysis of the magnetic circuit.