Technology & Case Studies

NIDEC's Technical Capabilities

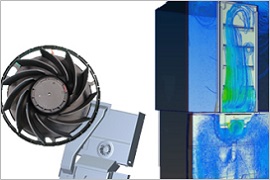

Thermal solutions

Nidec combines a variety of heat-resistance products to offer them as solutions

Types and features of Nidec’s fan motors

This section explains the types and features of fan motors, the products that generate wind, transfer heat, and generate pressure.

Position Detection Technology Zignear® that realizes High-Precision Motor Control

Nidec has developed a new position detection technology Zignear®, which realizes high-precision motor control. The features and product application examples of Zignear® are introduced. Let’s look into the realized “Future Technology” now.

Submicron-Precision Machining Technology

High-precision machining technology, one of the core technologies of the Nidec group, has played an important role in our success story in the HDD motor market.

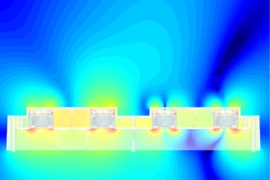

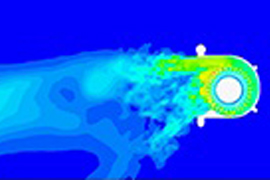

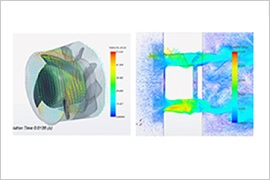

Nidec's Technical Capabilities CAE Technology Developed In-House

At Nidec, we utilize original modeling technology and analysis software developed in-house to optimize the design of our fluid dynamic bearings.

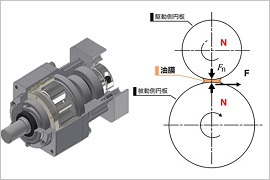

Fluid Dynamic Bearing (FDB) Technology

Nidec quickly began developing and manufacturing fluid dynamic bearings (FDBs), which are dramatically accelerating the increase in HDD capacity and noise reduction. We are pioneers in mass production of HDD spindle motors that use FDBs.

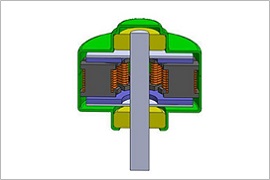

Brushless Motors

Nidec has a significant amount of experience in producing brushless DC motors featuring energy saving, long life, low noise, compact size and light weight.

Fundamental Technology for Innovative Motors

Higher torque density, less noise and reduced vibration—laying the foundation for the motors of tomorrow

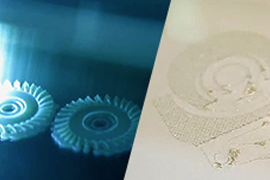

Rapid Prototyping

Exceeding the Needs of our Customers with Shorter R&D Cycles and Reduced Costs

Solutions Centered on Brushless DC Motors

Optimally designed modules combining motors with fans, blowers, pumps, gears and controllers

The Advanced CAE Technology behind our Optimally Designed Modules and Units

Coupled analysis and other advanced CAE tools cut down on development times and make development of advanced modules and units easier.

Traction Drive’s Noise Reduction Technology

Realizing automatic guided vehicles for silence-required places

Transfer robots that enable an optimum wafer transfer in a vacuum environment

Securing, even in an extremely high cleanliness vacuum environment, a degree of freedom equivalent to that in the air

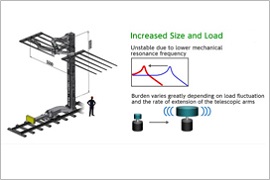

The Servo Technology of the Future

Completely new servo technology with support for control systems of unprecedented scale and precision.

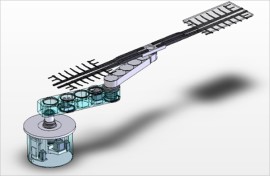

Semiconductor wafer transfer robot

Using Class-1 cleanliness technology to adopt the revolutionary 3-link arm link structure, saving space