1-3-1. DC Motor

The term "direct-current motor" is often abbreviated to "DC motor". Therefore, this book uses "DC motor" to refer to a direct-current motor.

The rotative force (torque) of a DC motor is proportional to the product of the strength of the magnetic field generated by the stator and the electric current flowing through the rotor. Magnetic flux of the field generated by the stator is called field flux.

On the other hand, the rotor is also called an armature, and the electric current flowing through it is referred to as armature current. The term "armature" refers to a device used to apply current to generate torque. It is not an "amateur", although the spelling may be confusing with that of "armature".

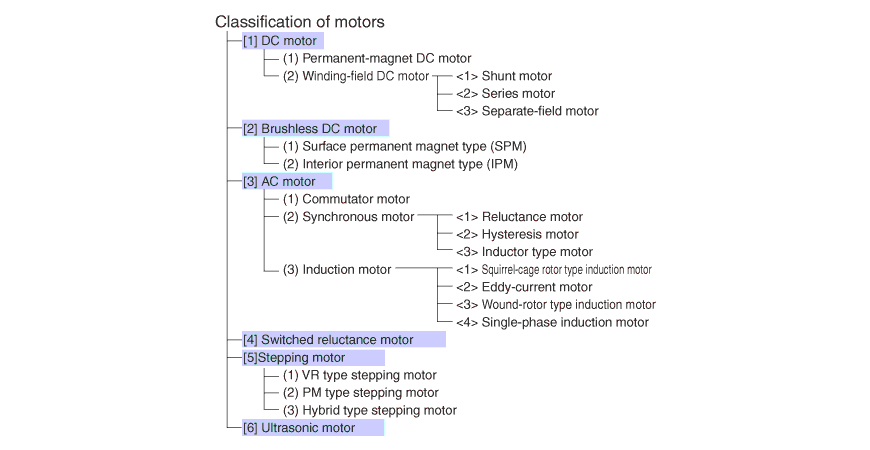

DC motors are roughly classified into two types, namely, permanent-magnet motors that use permanent magnets, and winding-field motors that do not use permanent magnets.

[1]-(1) Permanent-magnet DC motor

Permanent-magnet DC motors use permanent magnets and are most commonly used for models, automobile auxiliary devices, and other applications all over the world.

Permanent-magnet DC motors are classified into the following three types by armature (rotor) type:

- <1> Slotted type

- <2> Slotless type

- <3> Coreless type

The coreless type of <3> is also called the moving-coil type.

Details of these types and the relationship between the type of the permanent magnet and the characteristics will be discussed in Chapter 2.

[1] - (2) Winding-field DC Motor

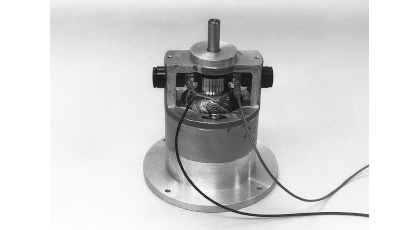

Fig. 1.5 shows a motor that generates field flux using electromagnets. Winding-field DC motors used to be primarily adopted for medium to large motors with up to about 1 horsepower (approximately 750 W) of output.

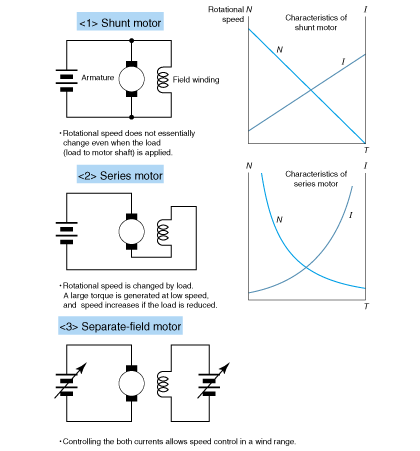

This type of motor is further classified into the following three types according to the difference in the method of connecting the field winding and armature winding (see Fig. 1.6).

[1]-(2)-<1> Shunt Motor

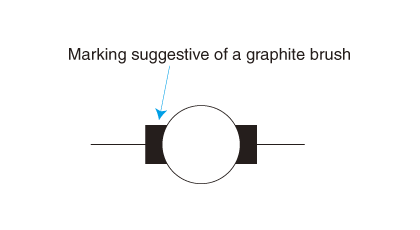

The shunt motor is composed of a concentrated winding stator and a commutator rotor as shown in Fig. 1.5, and the field (stator) winding and armature (rotor) winding are connected in parallel (Fig. 1.6<1>).

A feature of this motor is that the rotating speed does not change significantly if the load (on the motor shaft) varies. Such a feature is generally called shunt characteristics.

[1]-(2)-<2> Series Motor

In the series motor, the field winding and armature winding are connected in series. (Fig. 1.6<2>).

A feature of this motor is that the rotating speed changes significantly with load variation. It generates a large torque at startup or low speeds. When the load is reduced, the motor runs at a high speed.

Such a feature is generally called series characteristics. Utilizing this feature, this type of motor has been used in specific applications such as cranes, electric trains, and elevators.

At present, series motors are replaced with induction motors or synchronous motors containing inverters for variable speed control.

This motor also rotates on alternating current, which will be introduced later in connection with the commutator motor. However, rotating a motor designed as a DC motor on alternating current increases core loss and other types of loss, causing abnormal heat generation.

Incidentally, is it possible to change a shunt motor to a series motor and vice versa by switching the connection of the field winding and armature winding?

To put is simply, the aforementioned change is not possible from a practical standpoint. This is because the shunt motor winds a fine wire a large number of turns to configure a field winding (that has large resistance), while the series motor has a field winding consisting of a thick wire turned a small number of times (that has small resistance).

If the field winding and armature winding of a series motor are shunt-connected, it causes the field current to surge, which can burn the field winding out. Also, series-winding to connect the field winding and armature winding of a shunt motor will reduce the flow of field current (= armature current), preventing the motor from operating at the designed level of performance.

[1]-(3)-<3> Separate-field Motor

The separate-field motor has its field and armature windings connected to a separate power supply. (Fig. 1.6<3>).

A wide range of speed control is possible by separately controlling the current for both windings.