Central Technical Laboratory

Central Technical Laboratory is responsible for innovating elemental technologies, implementing the anticipatory development, and constructing ultra-precision machining technologies to enhance HDD spindle motors.

Functions and Roles

>The Central Technical Laboratory is a specialized organization devoted to research and development primarily for our core HDD spindle motor business that has a global market share of 80%. It is also the responsibility of the Laboratory to exploit expansion of applied technologies of FDBs (Fluid Dynamic Bearings) for which Nidec is the world's foremost manufacturer that has launched volume production of products for use in HDD spindle motors.

Utilizing accumulated know-how in the areas of elemental technology development, new model design and development technologies, ultra-precision machining technologies and production technologies, the Central Technical Laboratory responds to various requirements and requests on an ongoing and speedy basis. Such requirements and requests include anticipatory development, sample production, and technology transfer to the volume-production plants in Thailand, the Philippines and China and launch volume production in these areas, among others.

In order to provide unrivaled products to customers faster than our competitors and to solve their problems while at the same responding to social needs typified by requirements to save energy, the Central Technical Laboratory is carrying out its mission of accelerating Nidec business by utilizing the functions of the research and development institution and balancing product innovation with process innovation.

Product Range

HDD Spindle Motors

The Laboratory works to create innovative elemental technologies and carry out anticipatory development ahead of competitors so that as the leading manufacturer of HDD motors we can meet market demands for thinner, higher capacity products.

UltraFlo FDB

The Laboratory develops ultra-thin, low-noise, low vibration, high-speed fan motors by applying the Fluid Dynamic Bearing (FDB) technology cultivated in HDD motors.

Base Plates and Top Cover for HDD

Nidec has established an in-house product supply system through internal manufacturing of peripheral parts such as base plates and top covers. Nidec guarantees speedy supply of products.

R&D Activities

Development of Basic Technologies

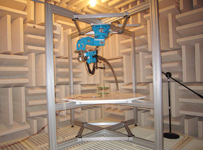

In order to support development of the high performance, highly reliable HDD spindle motors, the Laboratory carries out diverse numerical calculations (simulations), develops measurement technologies targeted at vibrations, acoustic values, electromagnetic fields, fluids and lubrication, as well as develops various materials including metallic materials, adhesives and lubricants (oil).In order to support development of the high performance, highly reliable HDD spindle motors, the Laboratory carries out diverse numerical calculations (simulations), develops measurement technologies targeted at vibrations, acoustic values, electromagnetic fields, fluids and lubrication, as well as develops various materials including metallic materials, adhesives and lubricants (oil).

Development of Component Manufacturing Technologies

The Central Technical Laboratory carries out research and development into elemental technologies for precision parts used in precision motors.

The Laboratory not only carries out development but also supports operations of volume production plans, and achieves high-level responses in every aspect of QCDS (Quality, Cost, Delivery, Service) requirements.

Development of Production Technologies

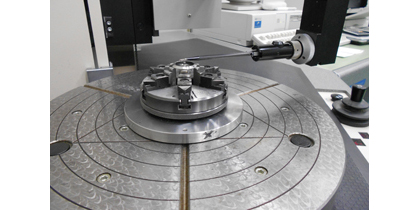

As the leading manufacturer of HDD motors in the world, the Laboratory carries out development of core and state-of-the-art technologies used for precision measuring, assembly and cleaning of parts.

The Laboratory Has Received International Standard ISO/IEC 17025 Certification as A Chemical Testing Institute.

The Laboratory is certified to international standards, which allows it to attest the data presented in the product analysis report that is conducted on substances specified in the EU RoHS directive.

Facilities and Experimental Apparatuses

(Resolution 12 nm)

(Stationary grinding machine)