NIDEC's Technical Capabilities

Fluid Dynamic Bearing (FDB) Technology

Nidec was one of the first companies to develop and manufacture fluid dynamic bearings.

FDBs have dramatically accelerated the density increase and noise reduction of HDDs.

The HDD is the key to producing high performance servers and PCs. The density and capacity of HDDs have been increased by improving various areas such as disk smoothness, magnetic recording method, and head sensitivity. However, from the end of the 1990s, vibration of HDD spindle motor bearings became a major cause of reduced data writing/reading accuracy.

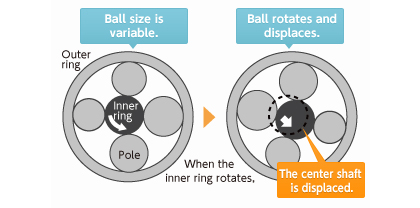

In 1994, Nidec launched mass production of HDD spindle motors that use FDBs (Fluid Dynamic Bearings) ahead of other companies. Production volumes increased from around 2000, and in 2002, FDB became mainstream bearings for HDD spindle motors. The reason for this was a dramatic increase in HDD recording density. In principle, conventional ball bearings could not eliminate the non-uniformity of balls. The variation between the balls caused the non-periodic vibration, the so-called the NRRO (Non-Repetitive Run Out), and this vibration interfered with the data writing and reading to/from the fine-pitch and high-density recording tracks.

Ball bearings have limited precision.

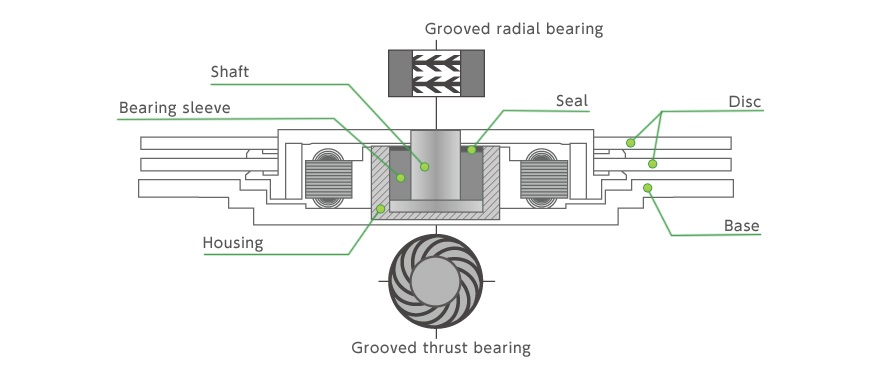

In the FDB chamber, a fluid such as oil exists between the bearings and the shaft. When the shaft rotates, the fluid's dynamic pressure generated by the rotation lifts the shaft from the bearings and rotates it smoothly. Low noise and small vibration can be expected from the damping characteristics of oil.

The principle of this fluid dynamic bearing had already been discovered by Tower, a British railway engineer, in 1883. It was widely known that bearings with a level of precision well beyond the limit of NRRO of ball bearings could be manufactured by applying a principle that had been known for a long time. Manufacturers were competing to complete studies on ways to apply this principle to HDDs. Meanwhile, Nidec launched mass production of these bearings earlier than its competitors. We maintain the No. 1 position in the production of HDD spindle motors, and today our global market share exceeds 80%.

The characteristics of FDBs, such as low noise, low vibration, impact resistance, low power consumption, and long life, are also applicable to other fields. FDBs are also used in fan motors of servers and notebook PCs. Nidec is not only working to expand these application areas; it is also striving to improve the original functions of FDBs. For example, we have developed software that simulates the motor behavior to shorten the design and development period for thinner HDD spindle motors that have higher performance. At the same time, we are also studying oil used for the FDBs, and working to develop oil that satisfies the requirements of lower friction and longer life.