Quest For Motors' Hidden Abilities and New Potentials

Lecture 7: The Advance of Transistors and Motors

The semiconductor device that brought about the rapid progress in electronics and compact motors was the bipolar junction transistor. It was followed by the thyristor, which revolutionized the control of large (industrial-use) motors. Because of its long name, the bipolar junction transistor is often called a bipolar or junction transistor, or simply "transistor" when referring to this type.

1. The use of the transistor allowed the development of various control methods

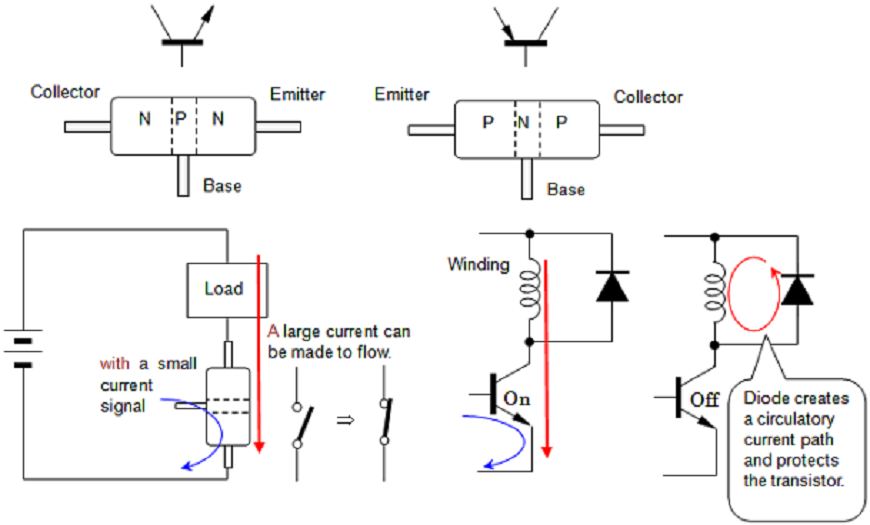

Since the transistor was invented in 1949 by Shockley, it took some twenty years before it widely replaced vacuum tubes as an amplification device of analog signals. It had to be further developed as a switching device to be used in motor control applications. The transistor has a sandwich structure consisting of either a PNP or NPN configuration. The latter type is more often used. This is used as a switching device in electric circuits; the principle is shown in Fig. 1. The greatest advantage compared to a mechanical switch is that it can switch at high frequencies.

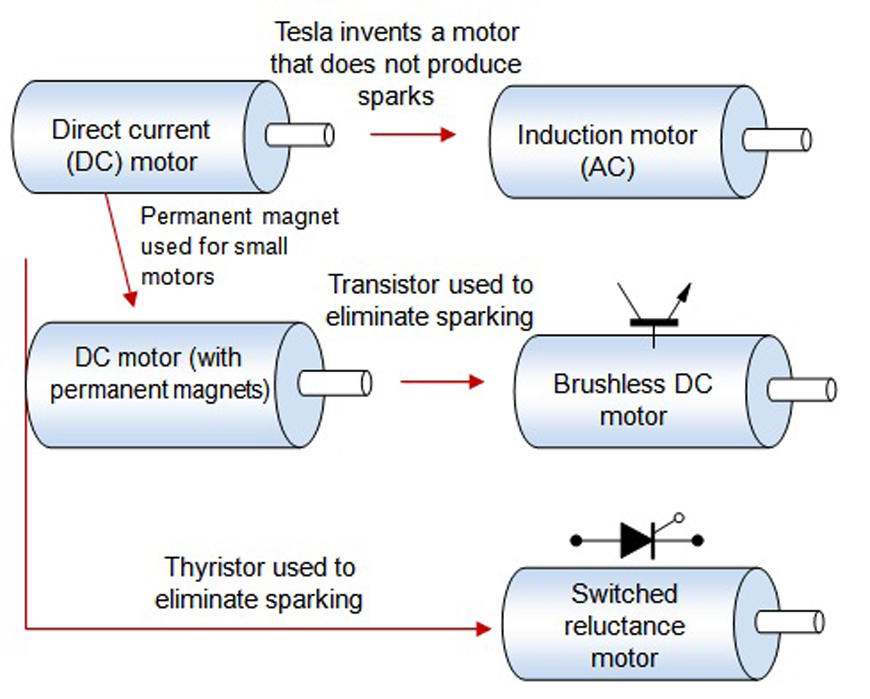

Methods were rapidly developed to use transistors to drive or control motors, of which stepping and brushless motors were typical. The latter has a greater overall economic significance compared to the former. The brushless motor has the properties of a dc motor but has no brushes. While Tesla invented an alternating current (AC) motor known as the induction motor when he tried to invent a motor that produced no sparking, when the brushes and commutator of the dc motor are replaced by transistors, we have a brushless motor.

its function as a switch, and the role of diodes

2. Development of transistor motor

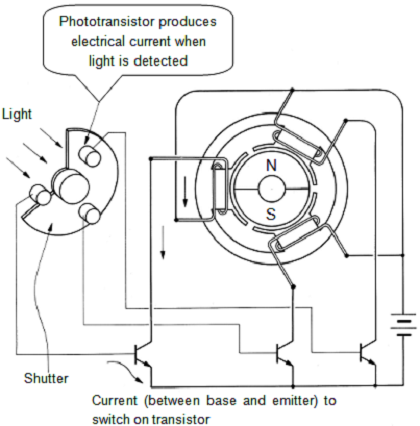

Figure 2 shows the principle of the brushless DC motor. There was a time in the early days when it was called a transistor motor. Many DC motors with brushes and a commutator are still in use today, but they are gradually being replaced by brushless motors. Here we shall examine the mysteries of the brushless motor. In the illustrated principle, a photonic device is used to detect the rotor position. In practice, a device called the Hall element is widely used as the position sensor.

The transistor motor (brushless DC motor) caused a major technological revolution in compact precision motors in the 1970s. A large demand for this motor existed in tape recorders, in which it was used in the mechanism to feed the magnetic tape at constant speed. Research and development efforts in this area had begun in the 1960s. Previously the hysteresis motor (which was described in Vol. 2) had been used for this purpose, but it had a low energy conversion efficiency, could be run only at certain speeds that were determined by the supply frequency, and displayed some speed flutter even when the frequency was accurately controlled.

The basic principle of the transistor motor is shown in Fig. 2. The important facts are that the properties of the DC motor are achieved by using

- a permanent magnet as the rotor, and

- a position sensor to determine the timing to excite the winding.

As a result, the torque is proportional to the current while the no-load speed is proportional to the voltage. Combined with a speed sensor mounted on the shaft, techniques have been developed to maintain a constant motor speed.

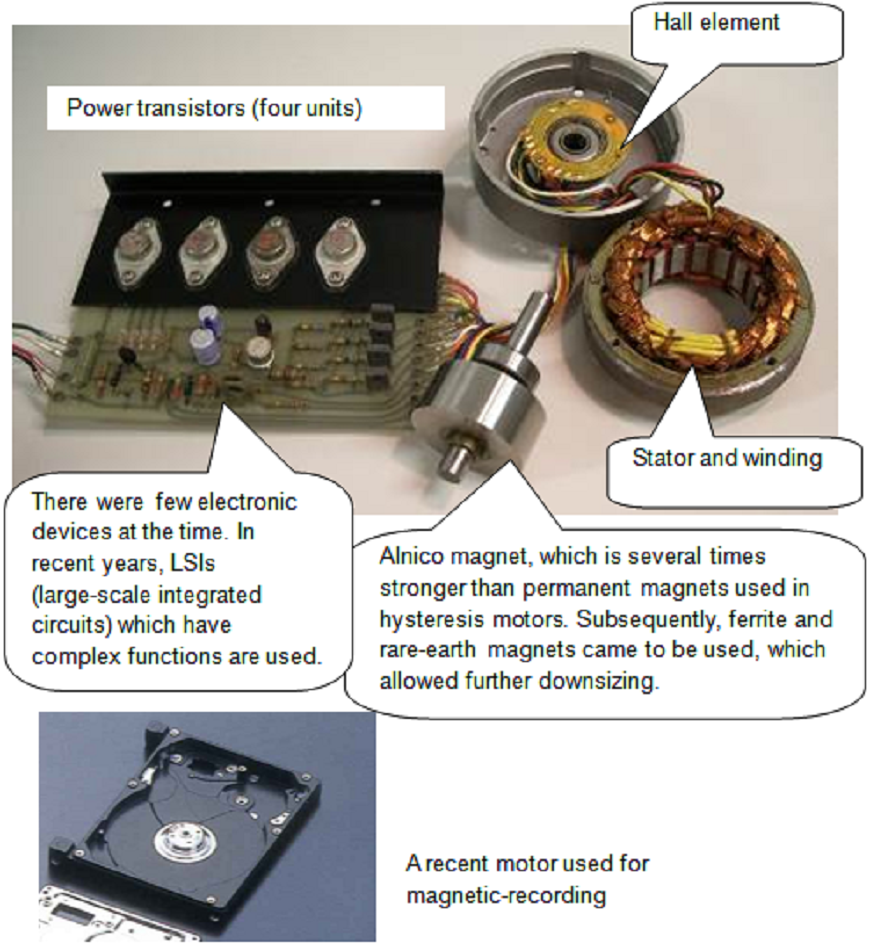

A typical example of an early transistor motor is shown in the photo of Fig. 3. The motor construction is inherited from that of the hysteresis motor. Hall elements are used to detect the rotor position, as in today's motors. Subsequent advances in permanent magnets led to the development of cheap ferrite magnets and powerful rare-earth magnets, which made it possible to use simple windings. The largest application of transistor motors lay in their use as compact spindle motors to turn the hard discs in PCs. The latest motors are about the size of a coin.

3. Invention of the thyristor propelled advances in power electronics

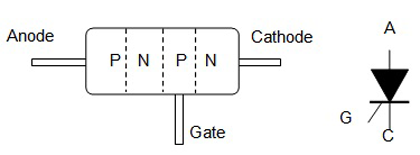

In Vol. 6, I wrote that a discharge tube called the thyratron made it possible to increase the efficiency of electrical-to-mechanical energy conversion. Based on the discovery at Bell Laboratories that the PNPN structure, shown in Fig. 4, functioned in a similar manner as the thyratron, it was developed and marketed as a product by General Electric Co. in 1957. This device, which at one time was called a silicon controlled rectifier (SCR), is the thyristor. As I mentioned in the previous volume, the controlled rectifier can be used to operate a motor in regeneration mode. Since the thyristor is capable of handling levels of current, voltage and power consumption far exceeding those of the transistor, it drastically advanced power electronics, including the control of large motors. Motors that came to be driven by thyristors (which are known today as large brushless motors) were at one time called thyristor motors.

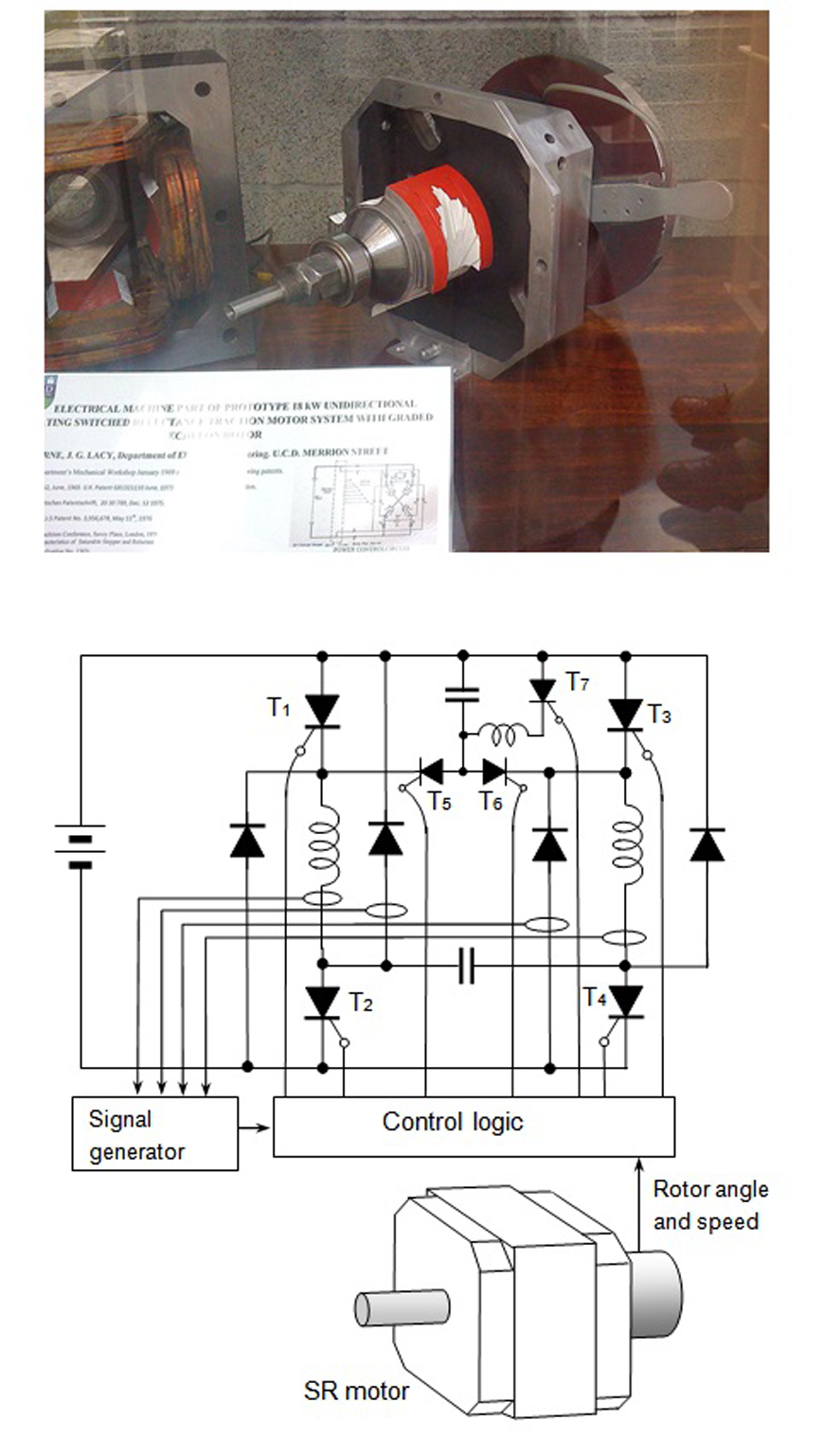

Today, permanent magnets are employed in brushless motors as well as stepping motors. The development history of stepping motors shows that permanent magnets were not used in early models. The combination of this type of stepping motor and a position sensor resulted in the switched reluctance (SR) motor. This is a typical example of an invention made possible by the thyristor. The photo in Fig. 5 shows the world's first SR motor, prototyped by John Byrne and Jim Lacy at University College Dublin for use as the traction motor of an electric vehicle. The drive circuit shows that it was necessary to use complex circuit technology to switch off the current in a winding. (In the next volume, we shall see that the advent of a new device known as the IGBT enabled such circuits to be made simpler.)

A note on the historical significance of the SR motor. There was a demand in electric railroads for a motor which can be controlled over a wide rotational speed range and had a large starting torque. This resulted in the development of a DC motor known the series wound motor. The shortcoming of the DC motor, however, is the sparking that takes place between the brushes and commutator, which can cause various problems and makes it necessary to carry out regular maintenance. A motor that did not produce sparks but could be operated over a wide speed range was needed. Such a motor was needed for electric vehicles as well. It was not long before motor experts recognized that the stepping motor that does not employ permanent magnets could be redesigned to produce large power, by using a thyristor to control switching according to the rotor position and speed, and achieve characteristics similar to the series motor.

prototype developed by Byrne and Lacy (T1-T7 are the thyristors.)

4. Mystery of motor development history

One of the wonders in the past forty years of motor development is the rate at which rapid downsizing was achieved. This was particularly notable in the technology of magnetic-recording for hard disk drives. This is what makes today's cloud computing possible. This was partly due to the development of powerful permanent magnets and methods of their application, but also important were the microfabrication of semiconductors and the increase in recording density. Japan has been at the forefront in the technology of fine positioning of the magnetic head, the development of permanent magnets for motor use and materials suitable for magnetic recording, as well as research on recording methods. Perhaps this writer is not alone in feeling that the manner in which technological progress of brushless motors was propelled by the collaborative efforts among these fields constitutes a miracle.

Figure 6 shows a diagram showing the development flow of the motors mentioned above. As we shall see in the next installment, further development of the bipolar junction transistor led to a convenient device known as the insulated-gate bipolar transistor (IGBT), which replaced the thyristor for the control of large motors. The IGBT also made it possible to regenerate electricity more effectively.

This will be the theme of the next installment.

(February 13, 1910 - August 12, 1989)

An American physicist born in London, William Shockley invented the transistor along with John Bardeen and Walter Brattain; the three shared the Nobel Prize in Physics in 1956.

After the end of World War II, a solid-state physics group was formed at Bell Laboratories, which was directed by Shockley and chemist Stanley Morgan. Among the members were John Bardeen and Walter Brattain. Their goal was to find a semiconductor to replace vacuum tubes. Research began to progress after Bardeen suggested a theory of surface states that explained why the electrical field could not penetrate the semiconductor. In December, 1947, Bardeen and Brattain completed the transistor known as the point-contact type and confirmed its amplification functions. Although this was an important milestone in the development of semiconductor theory, it was difficult to manufacture on a practical scale.

Controversy later arose about whether Shockley, who was interested in a method which is today known as the field-effect type, had actually been involved in the invention of the point-contact transistor. Bardeen became fed up and left Bell Labs to pursue research in superconductivity. Shockley continued work on his own on a transistor called the junction type, and obtained a proof of the operating principle in April, 1949. This invention was the basis of today's bipolar junction transistor.

In Japan, Prof. Yasushi Watanabe, at the Research Institute of Electrical Communication, Tohoku University, received the news of the invention of the transistor in 1948, when he was summoned to GHQ (General Headquarters, Supreme Commander for the Allied Powers). Watanabe, who had been conducting research in a similar area and thus was aware of its significance, relayed the news to the Electrotechnical Laboratory, Ministry of International Trade and Industry, before returning to the university in Sendai. This marks the beginning of the semiconductor industry in Japan. This writer (Kenjo) once had the opportunity to hear from Prof. Watanabe some stories of that time, including some funny ones, and of efforts to obtain germanium.