Nidec Machine Tool Corporation

History

| 1939 | Imigrated as Hiroshima Plant of Toyo Machinery Company and started manufacturing lathes. |

|---|---|

| 1941 | Toyo Machinery Company has joined the Mitsubishi group. |

| 1944 | Kyoto Machinery Works of Mitsubishi Heavy Industries, Ltd. established (Uzumasa, Katsura).Started manufacture of cutting tools and engine valves for automobiles. |

| 1983 | Constructed Ritto Plant in Ritto, Shiga Prefecture in Japan. |

| 1986 | Constructed the Ritto Universal Machine Manufacturing Plant. |

| 2003 | Construction of No. 2 machine tool plant.Hiroshima plant moved and integrated to the Ritto plant. |

| 2005 | Acquired S.R.P. Tools, an Indian cutting tool manufacturer. |

| 2010 | Began production of gear cutting machines at Mitsubishi Heavy Industries (Changshu) Machinery Co., Ltd. In China. |

| 2012 | Acquired Federal Broach Holdings, LLC, a U.S. broaches and broach machine manufacturer. |

| 2015 | Established Mitsubishi Heavy Industries Machine Tool Co., Ltd. as an independent business unit. |

| 2021 | Under the Nidec Group.Established NIDEC MACHINE TOOL CORPORATION |

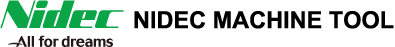

| 1939 |

Began production of lathes

|

|---|---|

| 1945 | Manufacturing of tools and jigs for aircraft engine |

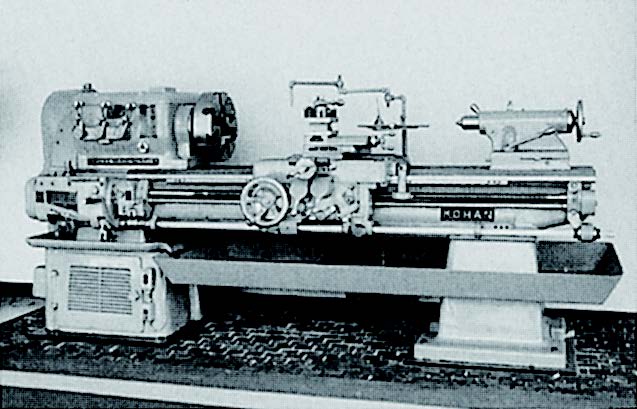

| 1953 |

Developed Japan's first transfer machine for processing crankcases of agricultural machinery

|

| 1960 |

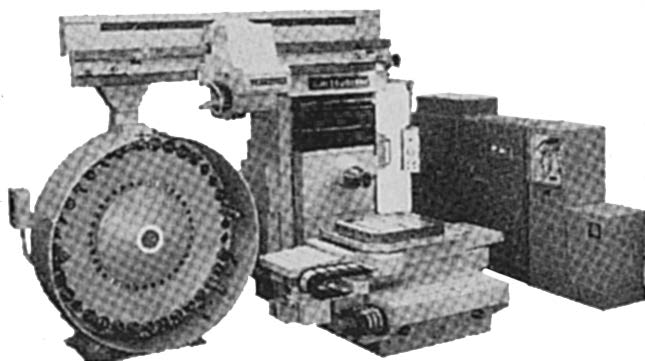

Began production of the Mitsubishi-Innocenti CWB milling and boring combined machine

|

| 1962 |

Developed Mitsubishi-Lorenz hobbing machine

|

| 1966 | Developed Mitsubishi-Reihauer shaving cutter grinder “NZA model” |

| 1967 |

Developed Japan's first NC horizontal boring mill MAF machine

|

| 1968 |

Developed the Mitsubishi horizontal machining center "MPA Series"

|

| 1969 |

Advancement in NC technology.Developed “Precision Position Feedback Detectors”

|

| 1973 |

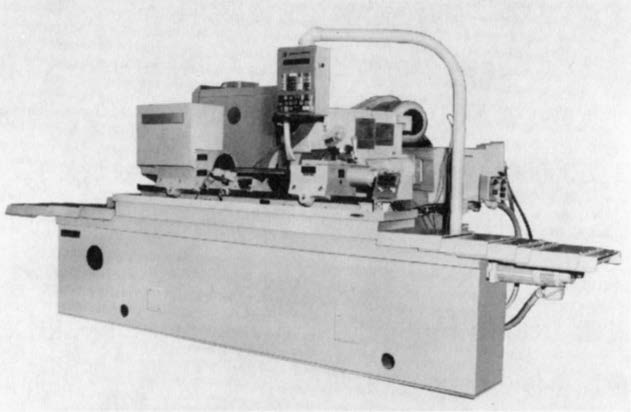

Developed Mitsubishi-Warner Swasey cylindrical grinding machine

|

| 1980 |

Developed Japan's first NC gear hobbing machine “GH400NC”

|

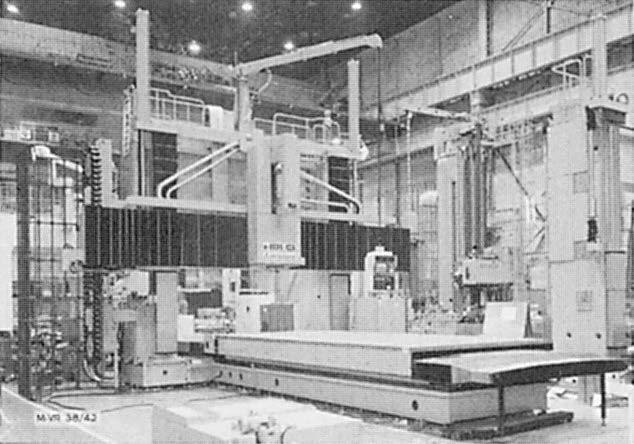

| 1985 |

Developed vertical precision milling machine "M-VR series".

|

| Developed “YAG Laser equipment” | |

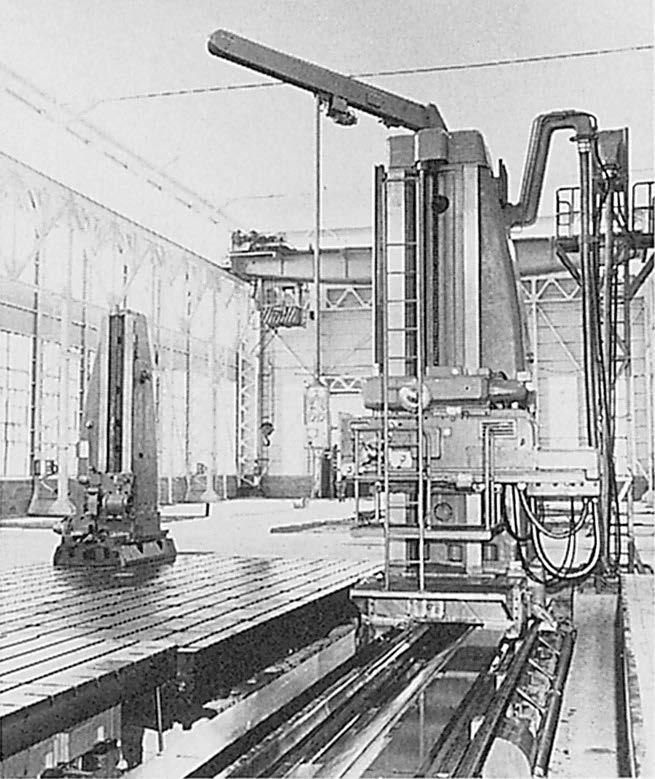

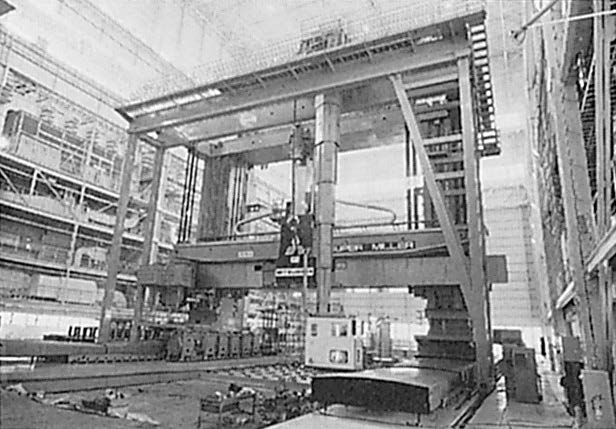

| 1986 |

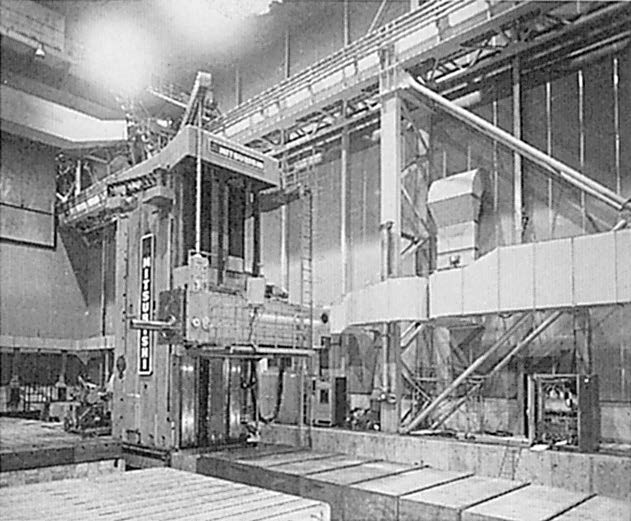

Completed the world's largest-class NC milling and boring combined machine "Supermiller"

|

| 1987 | Developed a high speed, high precision die and mold machine "M-KR series" |

| 1997 |

Developed a dry cutting system(SuperDry hobbing machines "GN series” and “SuperDry hob cutter”)

|

| 2002 | Began sales of SuperDry hobbing machines "GE series” |

| 2005 |

Developed the world's first wafer bonding machine operable at room temperature for MEMS

|

| 2006 |

Developed the micro milling machine "μV1"

|

| 2009 |

Developed world's first mass production type internally toothed ring gear grinding machine "ZI20A"

|

| 2014 |

Developed world's first “Super Skiving Cutter”

|

Developed Laser Micromachining System “ABLASER”

|

|

| 2016 |

Developed gear skiving machine “MSS300”

|

Developed large precision machines “MVR-Fx series”

|

|

| 2019 |

Developed the Direct Energy Deposition Additive Manufacturing System “LAMDA”

|