Machine Tools|Precision Machines|Precision Machines

Precision Machines

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

We offer a product lineup of Precision Machines that can handle various workpiece sizes.

Precision Machines

μV1

- Amount of travel (X × Y × Z

axis)

450 × 350 × 300 mm - Max. spindle speed

40,000min-1

μV1-5X (5-axis machine)

- Maximum workpiece size (mm)

⌀160 (an interference limit to be confirmed) - Max. spindle speed

40,000min-1

Precision Machines

μV5

- Amount of travel (X × Y × Z

axis)

900 × 550 × 450 mm - Max. spindle speed

30,000min-1

High-precision double column machining

center

LH250

- Amount of travel (X × Y × Z

axis)

2,500 × 1,000 × 600 mm - Max. spindle speed

20,000min-1

Features

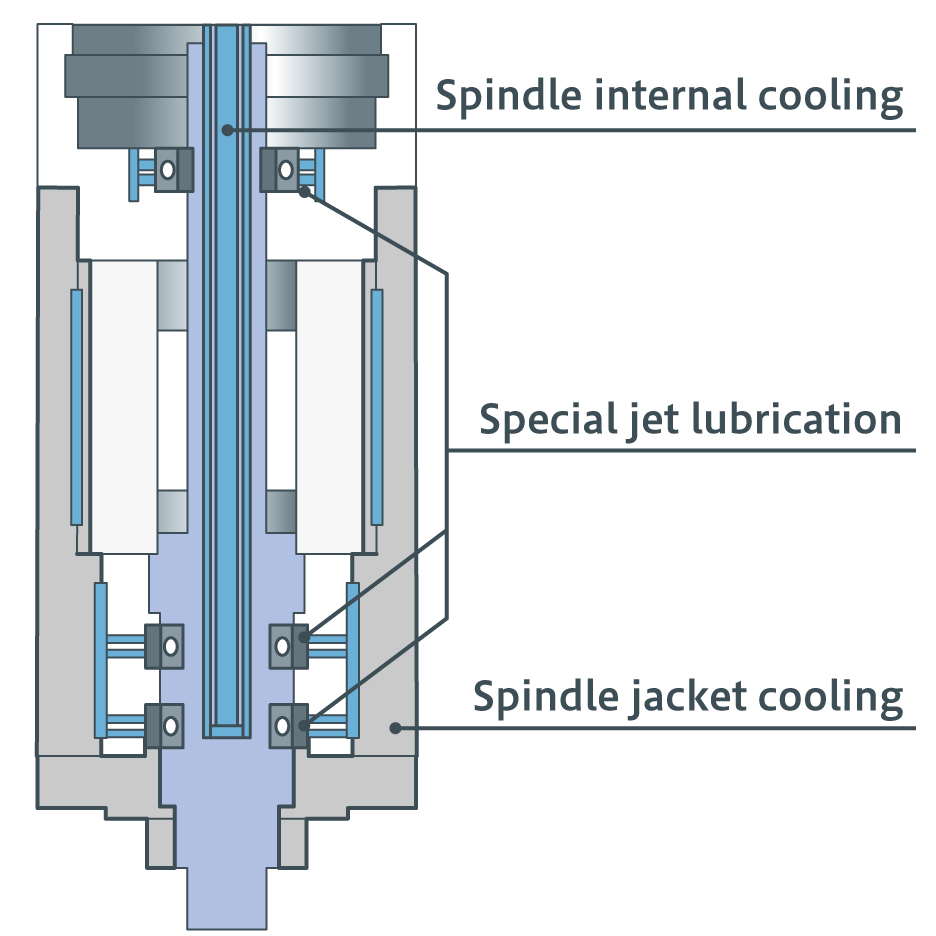

It achieves high-speed, high-precision processing thanks to the spindle equipped with internal cooling and special jet lubrication.

Lubricating oil controlled to the optimum temperature is supplied not only to the jacket part of the spindle,

but also directly to the inside of the rotating spindle. This allows oil to be completely recovered and

circulated while cooling the inside and outside of the spindle.

Moreover, fluctuation of the preload is

suppressed by supplying it to the bearings in the same way and minimizing the temperature difference between

the inner and outer rings.

Suppression of step between tools thanks to imaging tool measurement system (opt.)

The system tracks the lowest point of the tool that is displaced and automatically determines that the displacement is saturated using proprietary logic (stability confirmation) before executing tool length correction.

Specifications

| Item / Model | μV1 | μV1-5X (5-axis machine) | μV5 | |

|---|---|---|---|---|

| Table size (mm) | 500 × 400 | ⌀100 | 1,050 × 500 | |

| Max. workpiece size (mm) | W: 500 × D: 495 × H: 300 (an interference limit to be confirmed) |

⌀160 (an interference limit to be confirmed) |

W: 1,050 × D: 700 × H: 450 (an interference limit to be confirmed) |

|

| Axis travel | X-axis (mm) | 450 | 900 | |

| Y-axis (mm) | 350 | 550 | ||

| Z-axis (mm) | 300 | 450 | ||

| B-axis | — | 130° | — | |

| C-axis | — | 360° | — | |

| Rapid traverse rate | X, Y, Z axis (mm/min) | 15,000 | ||

| B-axis (min-1) | — | 75 | — | |

| C-axis (min-1) | — | 100 | ー | |

| Spindle speed (min-1) | 400 to 40,000 | 300 to 30,000 | ||

| Spindle motor output (max.) (kW) | 7.5 | 15 | ||

| Taper size, tool shank | HSK-E32 | HSK-E50 | ||

| ATC tool storage capacity (pcs) | 18 (opt. 30, 36) | 18 | ||

| Machine weight (kg) | 5,500 | 10,500 | ||

| Item / Model | LH250 |

|---|---|

| Table size (mm) | 2,500x1,000 |

| Max. loading capacity (kg) | 3,000 |

| Axis stroke (X × Y × Z) (mm) |

2,500 × 1,000 × 600 |

| Distance from spindle end to table top (mm) | 200 to 800 |

| Taper size, tool shank | HSK-A63 |

| Spindle bearing diameter (mm) | ⌀80 |

| Spindle speed (min-1) | 200 to 20,000 |

| Spindle output (30-minute rating/continuous rating) (kW) | 22/18.5 |

| Rapid traverse rate (mm/min) | 12,000 |

| Cutting feedrate (mm/min) | 1 to 12,000 |

| Tool storage capacity (pcs) | 40 |

| Machine weight (kg) | 21,000 |