Special Feature 2015 - Looking Ahead 100 Years to Evolve into a Truly Indispensable Business

1. Reducing the World’s CO2 Emissions

Automobiles account for a significant

portion of global CO₂ emissions

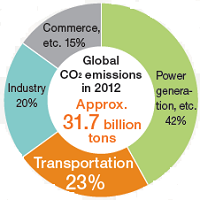

Worldwide CO₂ emissions amounted to approximately 31.7 billion tons in 2012,* 23% of which derived from transport. Reducing CO₂ emissions from automobiles is therefore crucial to global greenhouse gas reductions, prompting various countries to toughen up restrictions on automobile emissions. In the EU, where the world’s most stringent emissions standards are in effect, the company-specific total average CO₂ emissions per kilometer of new vehicles sold in the region is required to be 130 g or less from 2015, and 95 g or less from 2020. This regulatory trend has spread beyond the borders of the EU to countries such as Japan and the US, motivating automobile manufacturers to develop environmentally superior vehicles.

*Source: International Energy Agency 2014 report

Our Challenges

Reducing engine load through

electrically assisted power steering (EPS),

dual clutch transmission (DCT) and

no engine idling

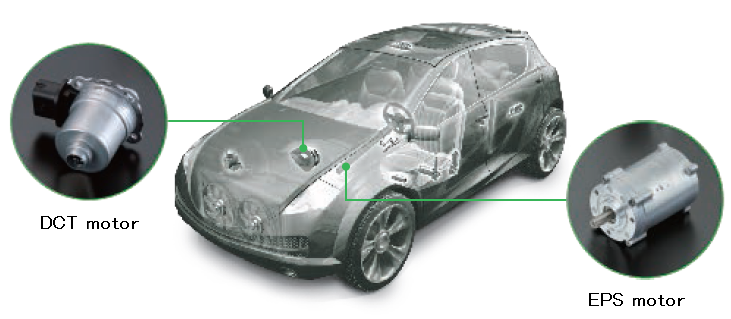

EPS and DCT

Reducing automobile CO₂ emissions involves reducing engine load as much as possible in order to consume less fuel. This requirement is motivating many of the world’s automobile manufacturers to adopt EPS. This is because replacing conventional hydraulic power steering systems with EPS can improve fuel efficiency by approximately 5%. Another growing trend, primarily among European automobile manufacturers, is the use of fuel-efficient DCT. The Nidec Group helps improve automobile fuel efficiency and reduce CO₂ emissions by offering motors for such EPS and DCT systems.

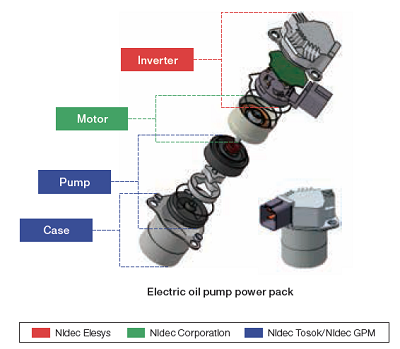

No engine idling

Car manufacturers are developing vehicles equipped with features to eliminate engine idling. “No engine idling” means shutting off the engine of a vehicle when it is parked, stopped, or waiting at a stoplight, and this reduces CO₂ emissions significantly. At the same time, some systems must continue to operate even when the engine is shut off, such as the oil pump used to boost the transmission’s oil pressure and the water pump used to keep the engine cool. Therefore, eliminating idling requires electric pumps to ensure the needed oil pressure and water flow rate. The Nidec Group provides the electric pumps (EOPs and EWPs) that are crucial for eliminating engine idling.

SR motors* for energy conservation in large vehicles

SR motors are used to drive a growing range of construction equipment (excavators, etc.), large vehicles for mining, and agricultural and other large industrial vehicles. The SR motor, with its high energy efficiency, can minimize electricity loss. Construction equipment, agricultural machinery, and similar types of equipment which operate hydraulically, are equipped with engines to boost hydraulic pressure. These vehicles use SR motors for vehicle drive, and the motors operate with electricity generated by the engine. CO₂ emissions can be reduced by not using engines to drive these vehicles.

*Switched reluctance motor