- Company:

- Nidec Machine Tool Corporation

- Representative:

- Haruhiko Niitani (Representative Director and Chairman)

- Address:

- 130, Rokujizo, Ritto, Shiga, 520-3080, Japan

- A Universal Head that is approximately 80% in size of conventional products but that still possesses industry-leading high-speed machining

- A Universal Head contributes to automated machining system and saves manpower of cast heavy duty cutting to high-precision mold finishing

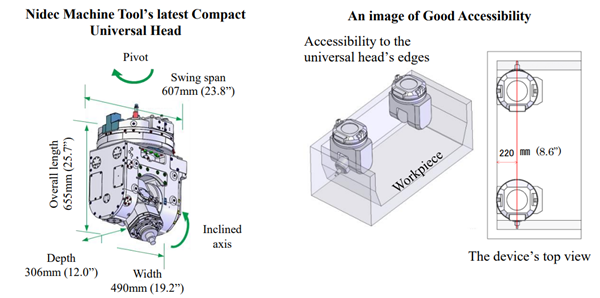

Nidec Machine Tool Corporation (represented by Mr. Haruhiko Niitani, president, and headquartered in Ritto, Shiga Prefecture) (“Nidec Machine Tool” or the “Company”), a Nidec Group company, today announced the launch of a new universal head (UH), an attachment of the Company’s MVR series of double column type milling machine with five-face machining capability The UH boasted an industry-leading compactness, by making the size approximately 80%*1of the conventional products, while maintaining the spindle capability with high output and speed.

This small UH enables a better accessibility between the tool-and the workpiece, as well as finished-surface quality and high-efficiency machining under ideal machining conditions, and its “light, thin, short, and small” features contribute greatly to mold and other products’ manufacturing processes. This UH’s sale is going to start at the Company’s “Large Machine Preview Show” to be held in Ritto, Shiga Prefecture, on Friday, February 02.

While made compact to improve its tool-workpiece accessibility and motion range, this new UH has an inclined axis with an extended tool-holding projection, enabling a better accessibility with a workpiece and the use of short and small tools. Additionally, even in machining processes that require long tools, this UH’s stiffer main spindle makes possible a variety of machining, from rough to finish machining. Also, with the UH able to approach up to 220mm (8.6”) to the wall, thanks to an improved swing span and interference range, the interference area with a workpiece has become smaller, and it can perform the precision machining on small and thin works and deep corners.

To secure better efficiency, this UH has a spindle speed of 20-6,000min-1, a spindle motor output of 15kW/420min-1, and a spindle maximum torque of 341N·m, while enjoying shorter non-machining time based on faster indexing time of each axis, shorter machining time due to stiffer attachments, and other features to improve productivity. Furthermore, the UH, which can perform indexing per angular 1 degree even during high output, has a high degree of freedom in machining, and can capable of handling a wide range of works, from cast heavy duty cutting to high-precision mold finish machining.

This UH can be installed into the Company’s double column type milling machining with five-face machining capability, i.e., MVR·Ax and MVR·Hx. The machines already delivered to the customers are also capable to install the attachment with additional construction.

Nidec Machine Tool Corporation stays committed to making proposals to contribute to addressing manufacturing automation, manpower saving, and other issues in the fields of machinery business and total solutions including attachments and peripheral devices.

*1. Comparison with the content of a universal head produced by the Company

| Overall length: | 655mm (-45mm) 、25.7” (-1.7”) |

| Width: | 490mm (-85mm) 、19.2” (-3.3”) |

| Depth: | 306mm (12.0) |

| Swing span: | 607mm (-81mm) 、23.8” (-3.1”) |

| Spindle taper: | BBT50 |

| Spindle speed: | 20 - 6,000min-1 |

| Spindle motor output: | 15kW/420min-1 |

| Spindle maximum torque: | 341N-m |

| Inclined axis’s swing motion range: | ±100° |

| Pivot’s swing motion range: | ±180° |