Special Feature 2022 - Integrated Report 2022

Environment

Realize a carbon-free society

Contributing to decarbonization through products

Basic stance

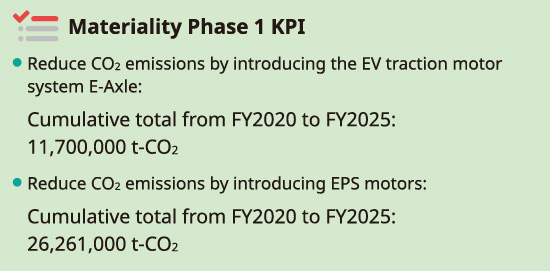

As global trends toward decarbonization are accelerating in response to intensifying climate change, Nidec, as a global business operator, is committed to the development and supply of products that will contribute to decarbonization. Specifically, focusing on products for automobiles, which are said to account for over 10% of CO2 emissions around the world, we have decided to set as a KPI the sales volume of products that reflect the global automobile electrification trend by converting it into the volume of CO2 emissions reduced.

While our contribution to decarbonization through our products has been recognized to some extent by our investors and other stakeholders, we are aware that the numerical data to support it is insufficient. In November 2020, we disclosed a reduction in CO2 emissions due to the introduction of the E-Axle EV traction motor system. We will identify a further reduction in CO2 emissions due to the introduction of electric power steering (EPS) motors, and further work to make visible our contribution to decarbonization through many other products.

Specific product example: Provision of high-efficiency, energy-saving motors

The key to reducing CO2 emissions from automobiles is to reduce the load on the engine and improve fuel efficiency. From this perspective, many car manufacturers around the world are increasingly adopting electric power steerings (EPS). The Nidec Group supplies EPS motors expected to improve fuel economy by about 5% compared to hydraulic motors.

The Group also offers electric oil pump motors to enable the idling stop function, and many other products that will lead to the reduction of emissions of CO2 and other air pollutants.

For other products, please see below.

Product-based Environmental Contribution

Initiatives in FY2021

The total number of units of our EV traction motor system “E-Axle” sold in FY2021 exceeded 370,000. The introduction of electric vehicles equipped with our motors into the market has helped reduce CO2 emissions. We achieved a reduction of 155,000 tons of CO2 emissions in FY2021. At the current pace, it is expected that we will be able to achieve our target of reducing CO2 emissions by a cumulative total of 11,700,000 tons by FY2025.

Toward the future

We launched mass production of the second-generation E-Axle in September 2022. Not to mention its high performance, the second-generation model is characterized by its reduced usage of materials and rare-earth elements through full use of our long-cultivated technologies to make products lighter, thinner, shorter, and smaller. We will contribute to the accelerating movement toward decarbonization through the enhanced provision of smaller, high-performance products with less environmental impact by replacing the product with its second-generation model, and even with its third- and fourth-generation models, which are still at the conceptual stage.

Reducing CO2 emitted in business activities

Basic stance

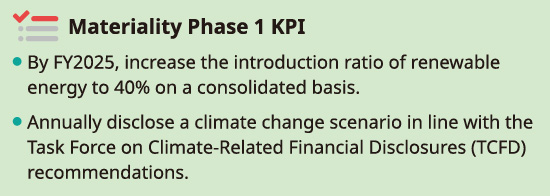

In addition to contributing to decarbonization through products, we are also committed to reducing CO2 emissions in business activities. As the Nidec Group’s energy use is expected to continue to increase due to the expansion of its production scale, including through M&A, we must establish a system whereby CO2 emissions can be reduced despite an increase in the total amount of energy used. Since electricity from thermal power generation accounts for over 80% of the total consolidated energy consumption of the Nidec Group, we have decided to achieve a dynamic shift to renewable electricity as our goal for the moment and set a KPI for it.

Specific action example

As an initiative to reduce CO2 emissions, we are advancing such measures as improving the efficiency of air conditioning systems, introducing energy-saving equipment, and switching to electricity generated entirely from renewable energy sources.

Initiatives in FY2021

In FY2021, we focused on introducing renewable electricity and worked to reduce CO2 emissions. The introduction ratio of renewable electricity in FY2021 was 10.5%, more than 3.5 times the FY2018 level, and total CO2 emissions from business activities (Scopes 1 and 2) were reduced by 23% from the FY2018 level to 513,000 tons. As for the TCFD, we have been preparing to express our support for its recommendations.

Toward the future

We will make these two efforts as a complementary pair: to improve the energy efficiency of our business and to introduce renewable electricity. First, by utilizing a tool to check the company’s energy efficiency and sharing best practices, we will improve the energy efficiency of facilities and equipment at each business site. Next, we will improve the total consolidated introduction ratio of renewable electricity by combining the introduction of renewable electricity at each business site and comprehensive renewable electricity procurement at the regional level. As for the TCFD, the Nidec Group announced its support for the TCFD recommendations in April 2022. Going forward, through scenario analysis, we will grasp the possible financial impact of climate-related risks and opportunities and incorporate the impact into our management strategies.

Manage waste and hazardous waste

Basic stance

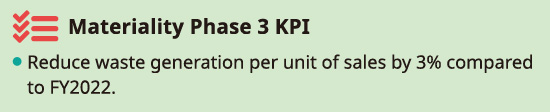

As increasing waste has been a global social problem in recent years, Nidec is working to establish a business system to help realize the effective use of raw materials. We have been making efforts not only to eliminate waste in manufacturing processes, but also to minimize the use of containers and packaging materials. Besides these, we are making continuous efforts to promote the recycling of waste by encouraging thorough sorting.

The Nidec Group pays sufficient attention to the use and storage of chemical substances at its business sites to prevent leakage thereof, while striving to reduce the use and emissions of chemical substances as far as possible as part of the initiative to improve and innovate production processes. The Group also utilizes its information systems and analysis techniques to satisfy international regulations concerning hazardous chemical substances contained in products.

We will continue to work on careful management of waste and hazardous waste in response to rising social demands.

Specific actions

Waste management

The amount of waste and valuable resources generated in FY2021 increased by 11% compared to the FY2020 level due to the increase in production volume. Even if the waste and valuables generated by plants can be sold, we believe that it is important to make efforts to reduce waste generation itself from the perspective of effective use of resources. We are committed to making effective use of raw materials through waste reduction in manufacturing processes and improvement in material yields by ascertaining the amount of generated waste on an individual main raw material basis.

Monitoring and disclosing the amounts of released and transferred chemical substances

In accordance with the PRTR system* based on Japanese law, the Nidec Group monitors and discloses the amounts of released and transferred chemical substances that are designated under the system and used at the Nidec Group’s sites in Japan.

* Pollutant Release and Transfer Register

Handle water risks

Basic stance

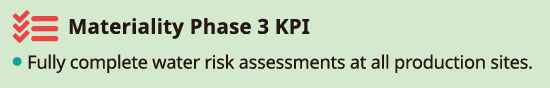

Water is the most important resource and is indispensable for people’s lives and industries. It is said that excluding seawater, icebergs and glaciers, only around 1% of water resources on the Earth are actually utilizable. Nidec recognizes the significant impact that depletion of water resources may have on its business continuation, such as shortening of operation hours or suspension of operations at plants, and has implemented conservation and reuse/recycling initiatives to save water resources. We are also engaged in water risk management through such measures as identifying risks in water intake and discharge for the continuation of business activities, and determining the impact of our water intake/discharge on peripheral areas and the water source areas.

Specific actions

Recycling of water

As demonstrated by Nidec Copal (Zhejiang) Co., Ltd., where reused/recycled water exceeded 50% of total water use in FY2021, active efforts have been made to promote the reuse and recycling of water at some of our business sites. However, looking at all the business sites covered in the Sixth Medium-term Environmental Conservation Plan,* the water reuse/recycling rate in FY2021 remained as low as 3.6%. With reference to the practices of business sites where water reuse/recycling has been promoted, we will work to encourage the other business sites to follow their excellent examples.

Meanwhile, the total volume of effluent water in FY2021 reduced by approximately 3% at production sites and approximately 1% at non-production sites compared to the FY2020 level, as a result of efforts to use water more efficiently at each site. We will continue to be thorough in carrying out improvement activities and conduct further water risk assessments.

* For details of the Sixth Medium-term Environmental Conservation Plan, please see below.

Medium-term Environmental Conservation Plan: Overview