- Nidec Machine Tool Corporation

- Kenichi Wakabayashi (Representative Director, President and CEO)

- 130, Rokujizo, Ritto, Shiga

- High-speed rapid traverse and a powerful spindle to improve productivity significantly

- Eco-friendly operations that reduce environmental load and running cost

Nidec Machine Tool Corporation, a Nidec Group company, announced today that it has launched its latest double-column machining center, MV12BxⅡ. Developed based on the concept of meeting “the machining needs of all ndustries,” this high-efficiency machine brings the best-in-class speed of a rapid traverse that significantly reduces non-cutting time, while achieving the highest productivity among all compact double-column machining centers. In addition MV12BxⅡ uses grease to lubricate all of its spindle and feed axes to improve energy efficiency and running cost, as well as featuring an electric power unit that enables ecofriendly operations. Offered as a machine that meets a diverse range of production requirements, such as high-precision surface quality to general parts machining, including light cutting to heavy cutting. MV12BxⅡ will be unveiled to the public at Nidec Machine Tool’s LargeMachine Preview scheduled on Tuesday, February 21 and Wednesday, February 22 at its Main Plant in Ritto, Shiga, Japan.

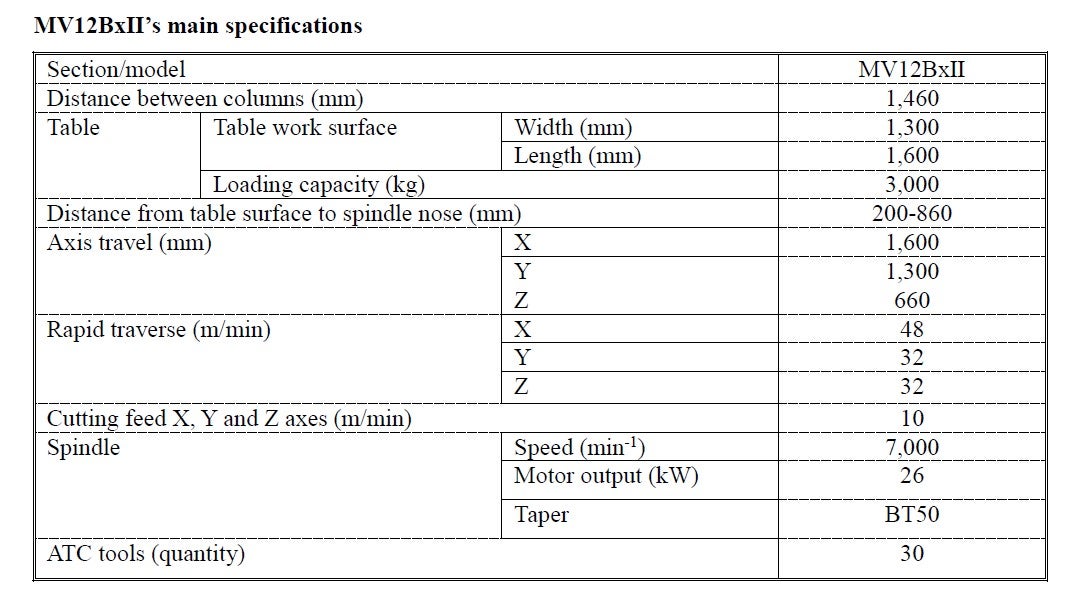

With the high-speed of the rapid traverse (Ⅹaxis: 48m/min., and Y- & Zaxes: 32m/min.), MV12BxⅡ realizes shorter non-cutting time, while its spindle’s maximum rotating speed has been improved to 7,000min-1, and its motor outpu has been increased to 26kW. Further, with a compact machine-installation space of 3.4 x 5.8m and a maximized range of operation (X-axis stroke: 1.6m, and Y-axis stroke: 1.3m), MV12BxⅡ’s productivity is second to none among double-column machining centers with a BT50 taper spindle in this class.

With the use of an energy-efficient and low-noise electric power unit to operate its pump only when necessary, MV12BxⅡ consumes much less power than conventional hydraulic units that are always running. In addition, the adoption of the tribology technology that Nidec Machine Tool has long developed and perfected, it enables the use of grease to lubricate MV12BxⅡ’s spindle and feeding axes, helping the machine to use less air and lubricant agent, to reduce running cost and operators’ workload.

Additionally, MV12BxⅡ has available a variety of user-satisfying options that were jointly developed with Nidec OKK Corporation, whose product lineup includes small- and medium-sized machining centers. The options include an automatic operator door, a coolant shower, and a selectable chip conveyor, is enough to meet various user needs.

Nidec Machine Tool stays committed to developing technologies for optimum productivity, safety, and environmental performance, and offering products that meet the diverse needs of production sites around the world.

For inquiries on the above product, please contact Sales Division of Nidec Machine Tool Corporation at +81- 77-552-9760.