Machine Tools|Machining Center|5 Axis Machining Center

HX500

Company: Nidec OKK Corporation

Achieves best-in-class compact space and high speed Rapid traverse rate of 65 m/min and maximum acceleration of 1G.

Achieves best-in-class compact space. Improved productivity with maximum acceleration of 1G and rapid traverse rate of 65 m/min.

- Contact information for product inquiry

- Contact us

Product's data

Product's specifications

| Rapid traverse rate | (X・Y・Z)65m/min(2559ipm)(1G acceleration) |

|---|---|

| Rapid traverse rate(A, B) | A:50 B:100min-1 |

| Maximum workpiece size | φ630×H400mm(dia.24.80”×15.75”) |

| Maximum loading capacity | 350kg(772lbs) |

| Spindle nose (Nominal number) | 7/24taper, No.40 |

| Spindle rotating speed | 100~15000min-1 |

| Spindle torque (15% ED/Continuous rating) | 70.7/35.3N・m(52/26 ft・lbs) |

| Spindle output (15% ED/Continuous rating) | 37/18.5kW(49.6/24.1HP) |

Features

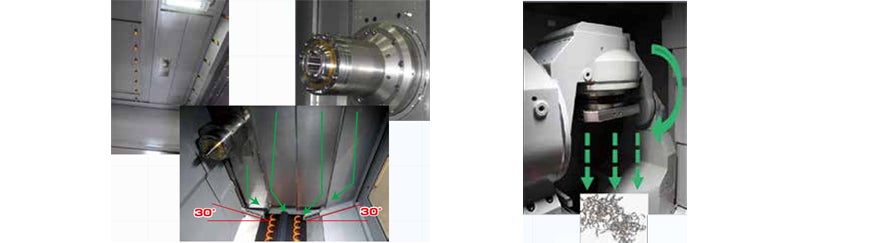

The A/B axes feature a reversible trunnion table driven by DD (Direct Drive) motors.

The rotary axes feature a trunnion table equipped with direct-drive motors as standard, enabling maintenance-free, backlash-free 5-axis machining. The trunnion table also employs a highly rigid dual-disc clamping system, delivering strong clamping forces of 4170 N·m on the A-axis and 2540 N·m on the B-axis. This ensures high rigidity during indexing operations. The A-axis travel range of +30° to ‒210° allows machining even with the table inverted, improving chip evacuation performance.

.jpg)

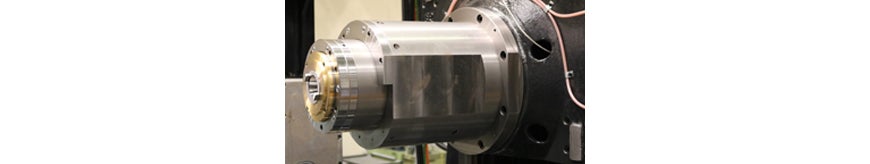

High productivity with a high-speed spindle and reduced non-cutting time

The spindle, with a speed of 15,000 min-1 (26/18.5 kW), delivers excellent performance in aluminum machining. With a rapid traverse rate of 65 m/min and maximum feed acceleration of 1G, non-cutting time is minimized, ensuring high productivity.

| Spindle taper | No.40 |

| Spindle speed | 15000min-1 |

| Maximum Output | 26/19.5kW(35/26HP) |

| Spindle diameter | ø70㎜(dia.2.76”) |

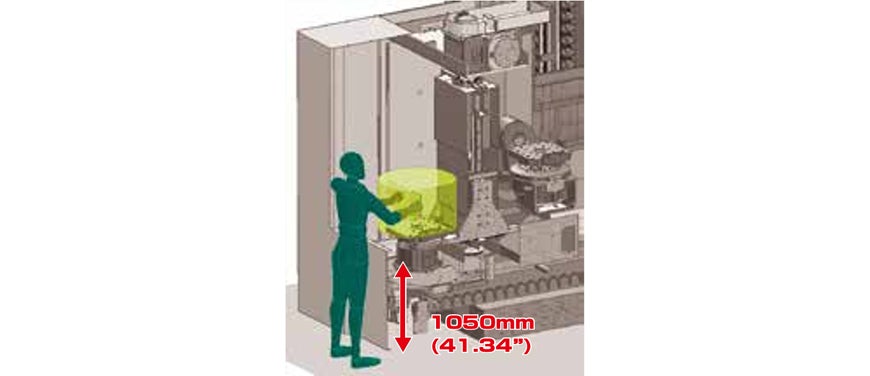

Axis travel and floor space

Can be installed within the same floor space as our horizontal machining centers of the same class.

.jpg)

Nidec OKK’s unique pallet change mechanism

Our proprietary pallet changer mechanism (Patent No. 7246253) keeps the pallet height during setup at 1,050 mm, ensuring excellent ergonomics. Workpiece setup can be performed comfortably without the need for steps.

Improved chip evacuation

Our bed with center trough structure, large-capacity ceiling shower, coolant curtain, and spindle nose cleaning nozzle all come standard.