Implemented Solutions

Brushless DC motors for Ovens

Highly-Controllable Brushless DC Motors that Allow for

Uniform Baking and Cooking Complicated Recipes

- NEEDS

- An oven with a large variety of cooking modes suitable for a wide range of recipes

- SOLUTION

- Enhanced functionality with brushless DC motors that enable precise control of temperature through highly accurate speed control

Contributing to Enhanced Oven Functionality by Taking Advantage of the High Controllability of Brushless DC Motors

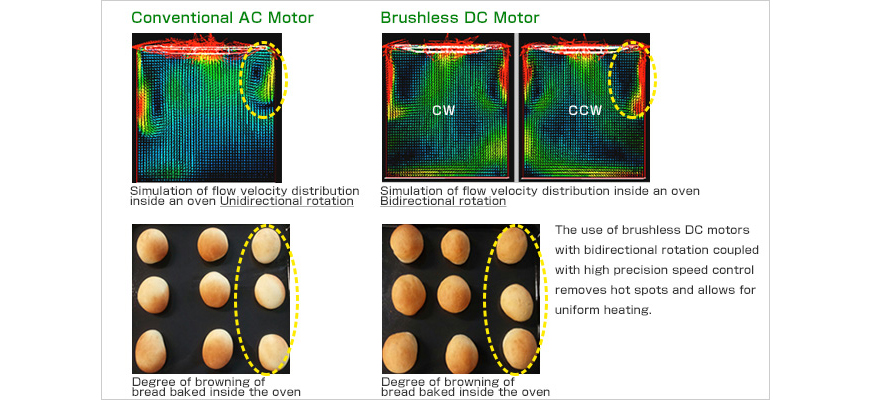

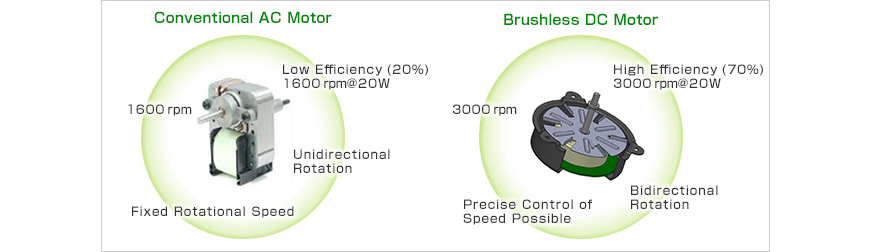

Compared with conventional AC shaded-pole motors, our brushless DC motors provide a slew of advantages including compactness, high efficiency and accurate speed control. By replacing the hot-air circulation motor in the back of the oven and the heat exhaust blower/motor in the ceiling of the oven with brushless DC motors, the inside volume of the oven can be increased without affecting the external dimensions. Alternatively, the external dimensions can be reduced while still maintaining the same volume. In addition, the accurate speed control of our brushless DC motors makes it possible to not only precisely control the overall temperature inside the oven, but also eliminate hot spots and ensure even heating with a great variety of cooking modes. Moreover, these highly-efficient brushless DC motors also follow the trend of home appliances with lower power consumption that originated in Europe and is spreading around the world.

Realization of Accurate Control Without Introducing Errors Under High Temperature and Electromagnetic Noise Conditions

In spite of their many advantages over AC shaded-pole motors, prior brushless DC motors have lacked the heat resistance necessary to be used inside ovens—where the temperature can reach 500 degrees Celsius—due to their built-in control circuits. Therefore, we made full use of our CAE technology to review the heat insulation and thermal control design from scratch and determine the optimal housing structure while taking the cooling impeller and the flow path in the oven into consideration, in order to achieve the necessary heat resistance. Another problem that presented itself was the electrical noise from the heater switch relay. This issue was overcome with an integrated hardware-software approach combining physical filtering of the circuit with increased software robustness to cope with noisy conditions and avoid malfunction. By overcoming these problems, we succeeded in developing a brushless DC motor capable of being used in ovens.