Machine Tools|Machining Center|5 Axis Machining Center

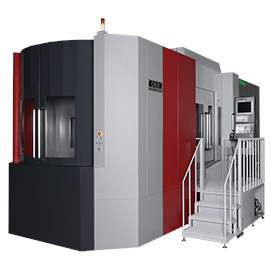

HM-X8000

Company: Nidec OKK Corporation

This model is excellent particularly at the high-efficiency machining of complex-shaped automotive and aircraft components!

With its spindle head using a tilted structure, this product can perform machining without tilting a heavy work, with high accuracy.

- Inquiries about this product

- Contact information for inquiries:

Product's data

Product's specifications

| Travel on X/Y/Z axis | 1300/1100/1550mm |

|---|---|

| Travel on A/B axis | 40 to -110/360deg |

| Palette's dimensions | □800mm |

| Table's maximum loadable weight | 2000kg |

| Rapid traverse rate | XYZ:48m/min |

| Spindle speed | 12000min-1 |

| Spindle inner taper | No. 50 |

| Number of storable tools | 60 (OP:40,80,116,120,176) |

The product's features

Structure

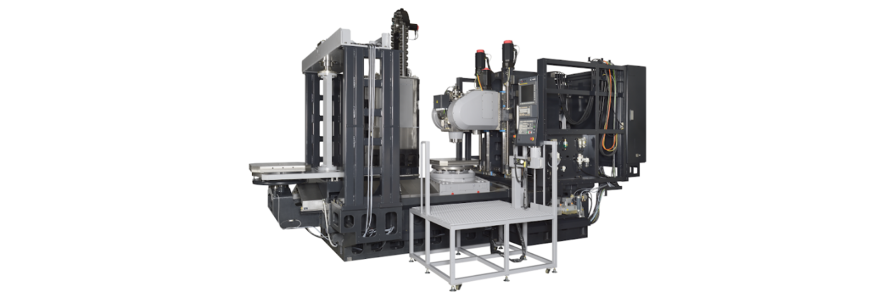

The machine's main unit uses a highly rigid structure from the HM Series, while its straight-line feeding mechanism adopted a highly rigid linear roller guide, to secure a high rigidity and accuracy.

Spindle

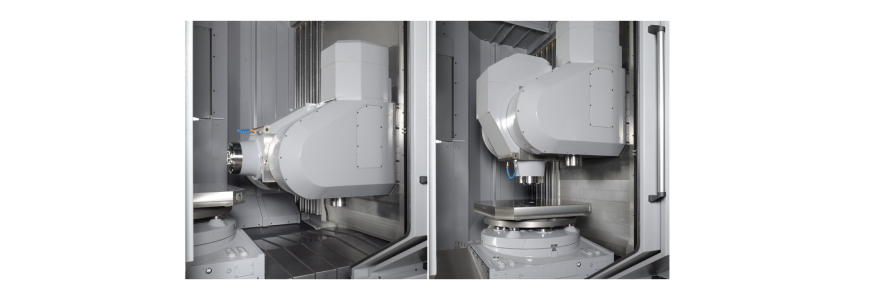

With the use of a tilted spindle head structure, this machine boasts better accessibility and visual recognition to its works than before, making itself easier to operate. In addition, with the spindle head tilted, the product can perform machining with its spindle positioned vertically or horizontally, expanding the range of machining layouts.

Ball screw

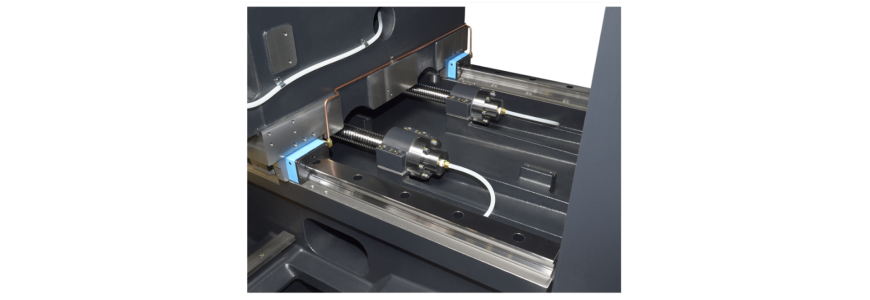

This machine adopts the large twin ball screw-based synchronous control drive system for its x- and y-axes, to suppress vibration and improve the quality of machined units. Additionally, all axes adopts the ball screw hollow cooling ball function and the ball screw thermal displacement correction function (Nidec OKK's uniquely developed correction function) as standard, to suppress thermal displacement and improve machining accuracy.

This video is in Japanese only