Machine Tools|Gear Cutting Machines|Gear Hobbing Machines

Gear Hobbing Machines G series

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

The G series offers a wide variety of gear hobbing machines for many kinds of products such as automobiles, aircraft, ships, and turbine generators.

Medium-size gear hobbing machine

GD30

- Max. workpiece diameter (mm)

φ300 - Max. module

8

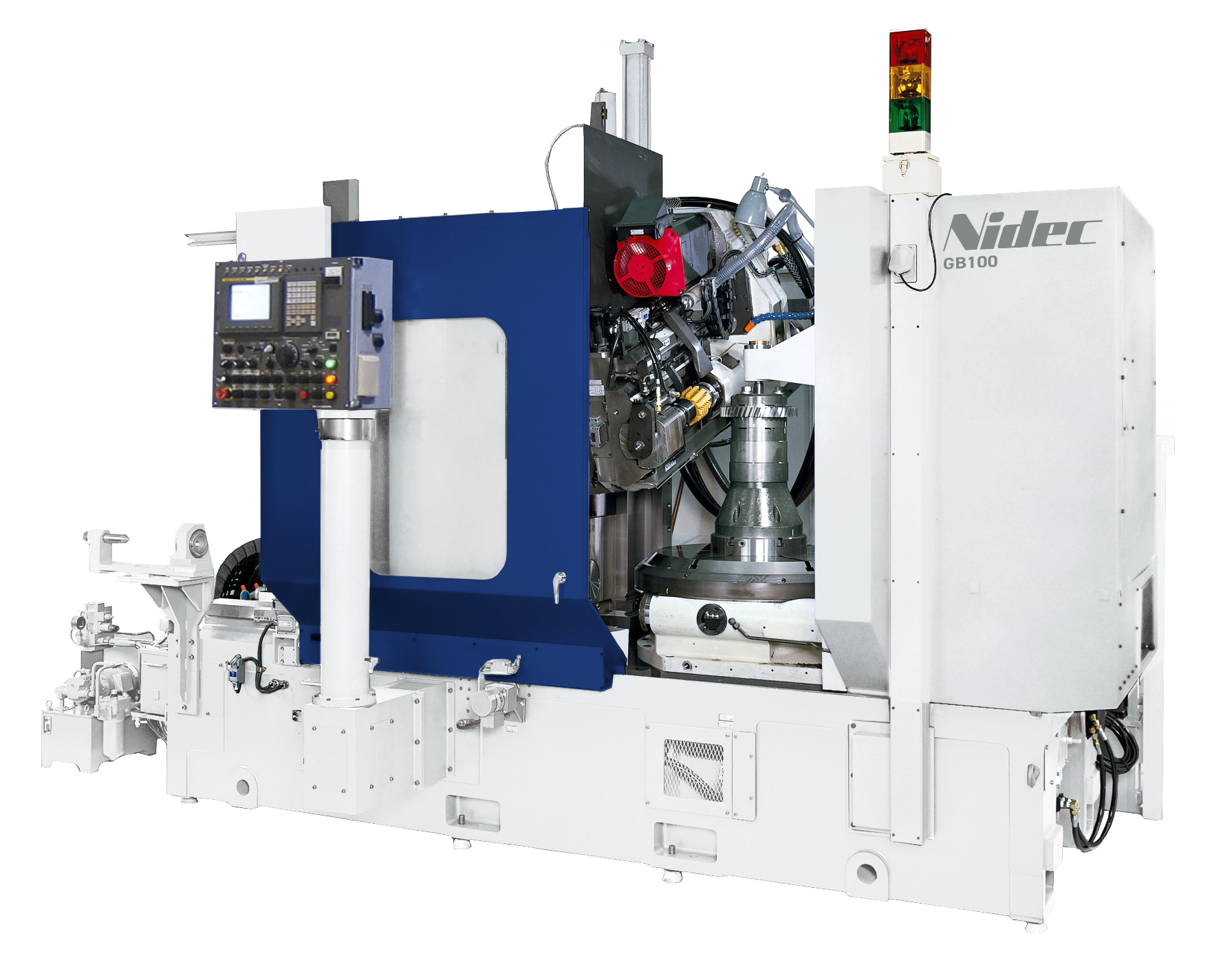

Large-size gear hobbing machine

GB100

- Max. workpiece diameter (mm)

φ1,000 - Max. module

14

Horizontal gear hobbing machine

GBH18

- Max. workpiece diameter (mm)

φ180 - Max. module

6

Features

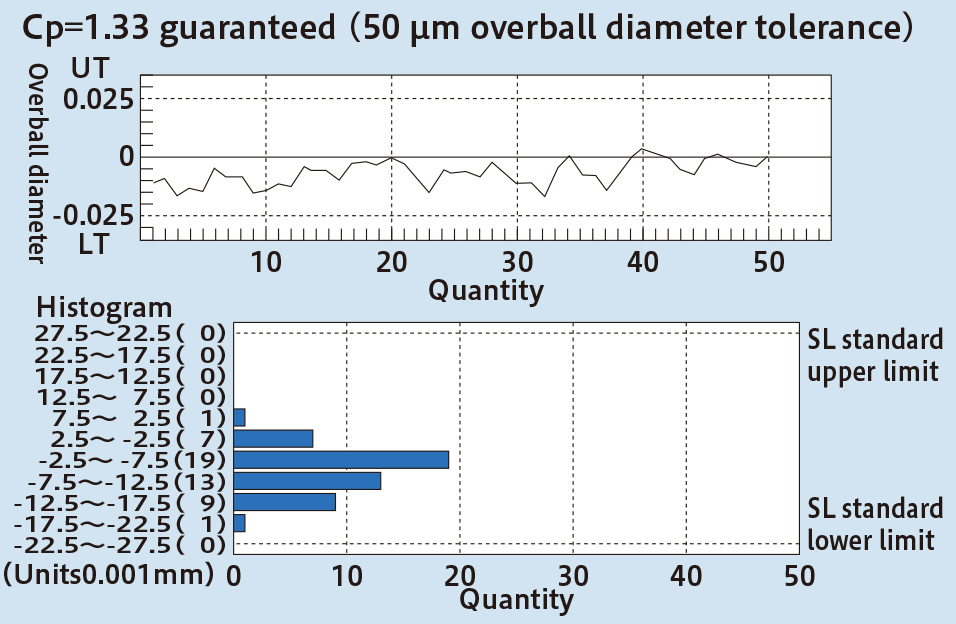

Excellent machining accuracy

Based on the highly rigid and highly accurate mechanical structure including the table, sliding surface, and feed shaft, this product pursues high processing accuracy from all aspects, such as improving positioning accuracy and reducing the effects of thermal displacement. The G series achieves JIS class 3 for high-precision gears and JIS class 5 [JIS B 1702 (1998)] for high production gears.

In addition, repeatability of processing precision is guaranteed to be Cp=1.33 for an overball diameter tolerance of 50 μm. Meets the needs of high precision.

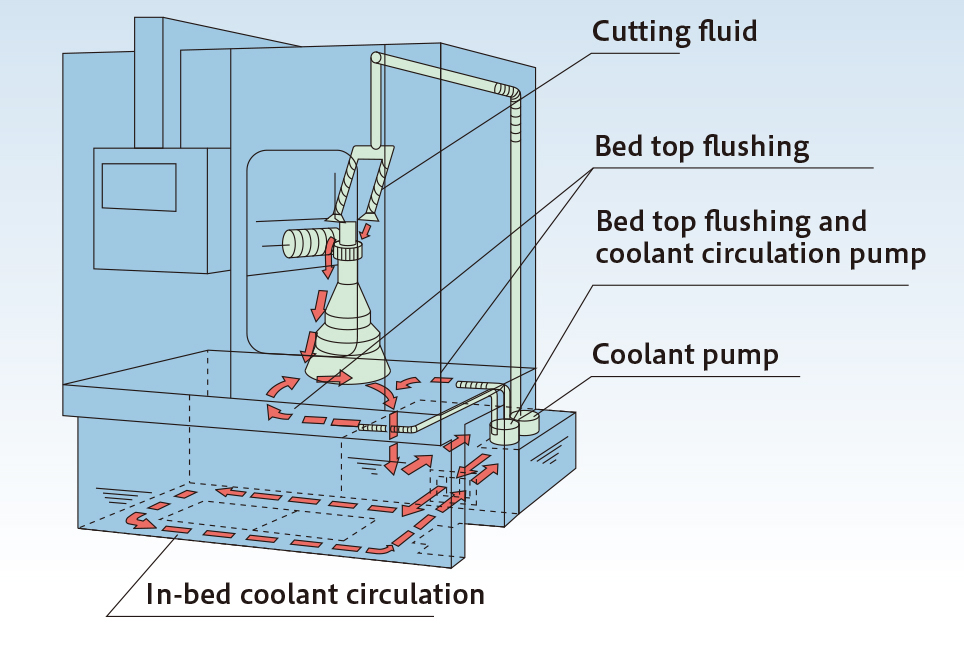

Stable processing quality is maintained by thorough measures against thermal deformation.

Dimensional changes to the processed workpiece are due to mechanical and thermal deformation that is caused when cutting fluid warmed by the processing heat is applied to the upper surface of the bed. To prevent this, by circulating the coolant in the bed, the heat distribution is made uniform and thermal deformation is minimized.

Specifications

| Item / Model | Vertical CNC gear hobbing machine | Horizontal CNC gear hobbing machine | ||||

|---|---|---|---|---|---|---|

| GD30 | GD50 | GB63 | GB100 | GBH18 | ||

| Max. workpiece diameter (mm) | ⌀300 | ⌀500 | ⌀630 | ⌀1,000 | ⌀180 | |

| 8 | 14 | 6 | ||||

| Axial travel (mm) | 300 | 500 | 700 | |||

| Radial travel method | Column traveling | Column traveling | Hob saddle traveling | |||

| Hob and work centers distance (mm) | 40 to 340 | 50 to 625 | 30 to 155 | |||

| Hob | Max. diameter × length (mm) | ⌀150 × 230 | ⌀210 × 240 | ⌀120 × 200 | ||

| Shift (mm) | 180 | 200 | 160 | |||

| Rotation speed (min-1) | 75 to 750 (opt. 120 to 1,200) | 30 to 225 (opt. 40 to 400) | 150 to 1,000 | |||

| Axial cutting travel (mm/min) | 1 to 1,000 | 0.1 to 300 | 1 to 400 | |||

| Indexing tooth number | 5 to 1,000 | 5 to 1,000 | 6 to 1,000 | 6 to 1,000 | 4 to 200 | |

| No of contolled axes | 5 | 5 | 5 | |||

| Total electric power (kVA) | 33 | 33 | 20 | |||

| Machine weight (kg) | 10,000 | 10,500 | 16,000 | 18,000 | 7,000 | |