Machine Tools|Gear Cutting Machines|Gear Shaping Machines

Gear Shaping Machines S series for large diameter gears

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

The S series gear shaping machines are ideal for processing medium and large workpieces.

SC40

- Max. workpiece diameter (mm)

External gear: ⌀400

Internal gear: ⌀400 (⌀250 + cutter dia.) - Max. module

8

SC63/100

- Max. workpiece diameter (mm)

External gear :φ650mm / φ1,000mm

Internal gear : ⌀650mm / ⌀1,000mm - Max. module

8 / 12

Features

Excellent machining accuracy

Based on the highly rigid and highly accurate mechanical structure including the table, sliding surface, and feed axes, this product pursues high machining accuracy from all aspects, such as improving positioning accuracy and reducing the effects of thermal displacement. The S series achieve JIS class 5 [JIS B1702 (1998)] for high-precision gears (spar gears).

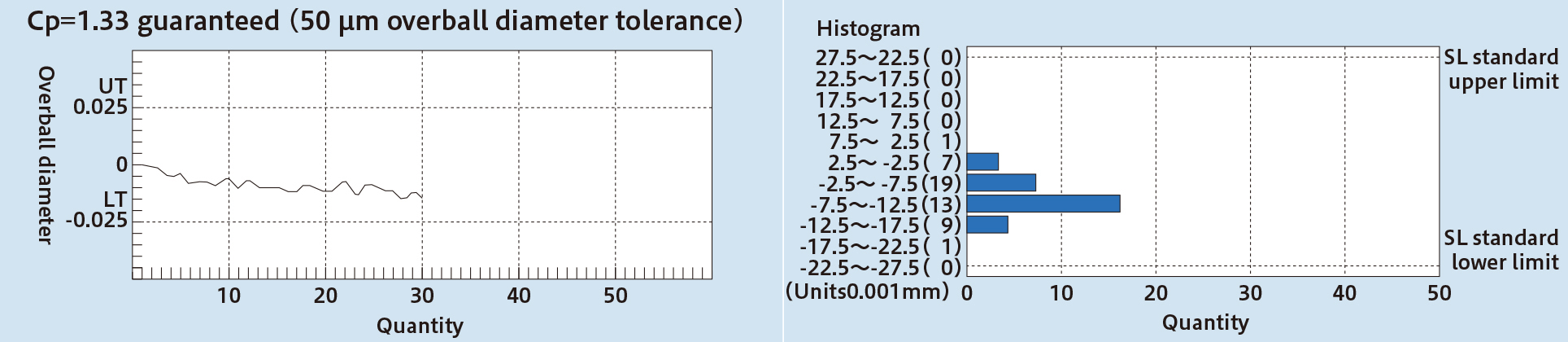

In addition, repeatability of processing precision is guaranteed to be Cp=1.33 for an overball diameter tolerance of 50 μm using thermal displacement compensator. S series meet the needs of high precision and can handle even challenging orders with reliable quality.

Stable machining quality

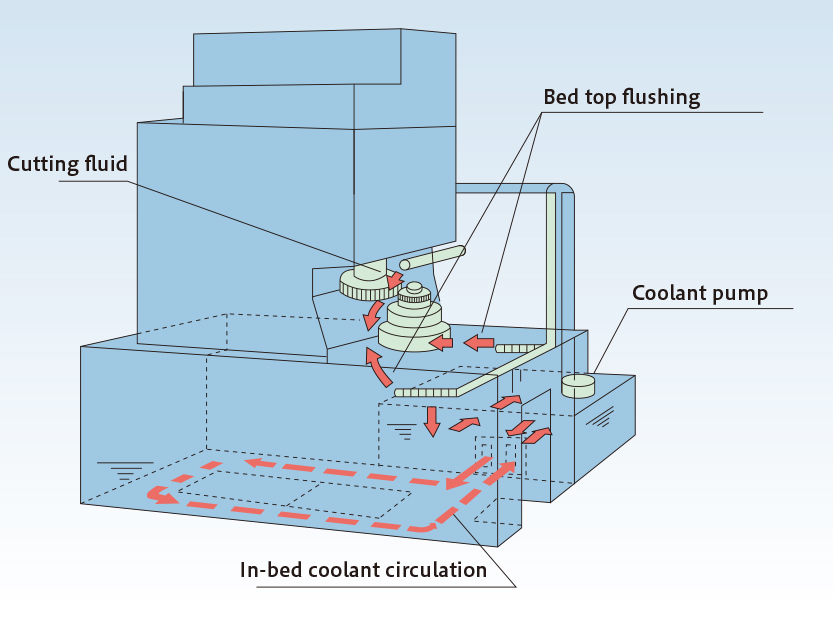

Stable machining quality is maintained by thorough measures against thermal deformation.

When cutting oil becomes heated during the machining process and splashes over the surface of the machining bed, the workpiece may experience dimensional variations due to mechanical thermal displacement.

To prevent this, some coolant is circulated within the bed to maintain uniform thermal distribution, minimizing thermal displacement.

Specifications

| Item / Model | SC40CNC | SC63CNC | SC100CNC | |

|---|---|---|---|---|

| Max. workpiece diameter | External gear (mm) | ⌀400 | ⌀650 | ⌀1,000 |

| Internal gear (mm) | ⌀400 (⌀250 + cutter dia.) |

⌀650 | ⌀1,000 | |

| Max. module | 8 | 8 | 12 | |

| Max. gear width (mm) | 115 | 200 | 200 | |

| Spindle stroke speed (min-1) | 50 to 800 | 30 to 300 | 30 to 300 | |

| Number of cuts | 1 to 4 | 1 to 4 | 1 to 4 | |

| Cutter spindle diameter (mm) | ⌀100 | ⌀120 | ⌀120 | |

| Main motor (continuous rating) (kW) | 7.5 | 16 × 2 | 16 × 2 | |

| No of controlled axes | 5 | 5 | 5 | |

| Total electric power (kVA) | 31 | 41 | 41 | |

| Machine weight (kg) | 10,000 | 17,000 | 17,000 | |