Machine Tools|Cylindrical Grinding Machines|Cylindrical Grinding Machine

Cylindrical Griding Machines P series for mass production

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

The P series enables mass production with high productivity.

PD23

- Grinding wheel slide type

angular/straight - Swing (mm)

φ230 - Center distance (mm)

350 - Max. grinding diameter (mm)

φ200 - Max. grinding weight (kg)

50

PD32

- Grinding wheel slide type

angular/straight - Swing (mm)

φ320 - Center distance (mm)

500/1,000/1,500 - Max. grinding diameter (mm)

φ300 - Max. grinding weight (kg)

150

Features

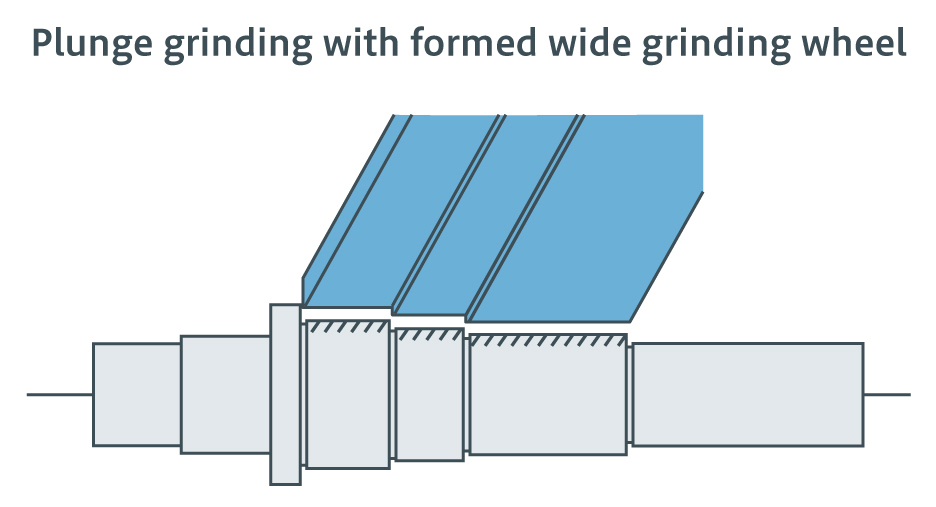

High-speed heavy grinding at grinding wheel peripheral speed of 60 m/s (opt. 80 m/s, PD32)

- The grinding wheel axis is equipped with an 11 kW high output motor as standard. (PD32)

- The standard specifications are a grinding wheel peripheral speed of 60 m/s and a grinding wheel width of 120 mm (opt. max. 145 mm), enabling high-speed single-shot heavy grinding with a wide grinding wheel. (PD32)

Specifications

| Item / Model | PD23 | PD32 | |||

|---|---|---|---|---|---|

| Capability | Grinding wheel slide type | Angular/straight | Angular/straight | ||

| Swing (mm) | ⌀230 | ⌀320 | |||

| Center distance (mm) | 350 | 500 | 1,000 | 1,500 | |

| Max. grinding diameter (mm) | ⌀200 | ⌀300 | |||

| Max. grinding weight (kg) | 50 | 150 | |||

| Grinding wheel | Outer diameter (mm) | A:⌀510 P:⌀455(⌀510) | ⌀510(⌀610) | ||

| Inner diameter × width (mm) | ⌀127 (⌀152.4 ) X50 (75) | ⌀203.2 X 120 ( 145*) | |||

| Peripheral speed (m/s) | 60(80) | 60(80) | |||

| Grinding wheel stand (X-axis) | Rapid traverse rate (m/min) | ⌀20 | ⌀20 | ||

| Grinding feedrate (mm/min) | ⌀0.0001 to 20,000 | ⌀0.0001 to 20,000 | |||

| Command unit (µm) | ⌀0.1 | ⌀0.1 | |||

| Grinding wheel stand (Z-axis) | Rapid traverse rate (m/min) | 12 | 12 | ||

| Traverse speed (mm/min) | 0.0001 to 12,000 | 0.0001 to 12,000 | |||

| Command unit (µm) | 0.1 | 0.1 | |||

| Head stock | Rotation speed (min-1) | 8 to 800 | 10 to 500 | ||

| Number of conversions | Continuous | Continuous | |||

| Center taper | MT No. 4 | MT No. 4 | |||

| Tailstock | Stroke (mm) | 150 (including normal stroke 35) | 50 | ||

| Clamp method | Spring | Spring | |||

| Forward/backward method | Manual lever | Manual lever | |||

| Center taper | MT No. 4 | MT No. 5 | |||

| Taper fine adjustment stroke (mm) | ±0.125 | ±0.125 | |||

| Dresser | Single point dresser holder | Single point dresser holder | |||

| Motor | Grinding wheel motor (kW) | 5.5 (7.5) | 11(15) | ||

| Spindle motor (kW) | 1.6 | 2.1 | |||

| Power capacity (kVA) | 15(18) | 23(28) | |||

| Floor to work center height (mm) | 1,000 | 1,105 | |||

| NC device | FANUC 32i-Model B | ||||

| Machine weight (kg) | 6,000 | 7,000 | 8,500 | 10,000 | |

Remarks () is an option

*When the 145 mm wide grinding wheel is installed, the

grinding wheel axis uses rigid ball bearings.