Machine Tools|Cylindrical Grinding Machines|Cylindrical Grinding Machine

Cylindrical Griding Machines R series for general purposes

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

The R series achieves excellent high precision grinding for general purposes.

RD23

- Grinding wheel slide type

angular/straight - Swing (mm)

φ230 - Center distance (mm)

350 - Max. grinding diameter (mm)

φ150 - Max. grinding weight (kg)

80

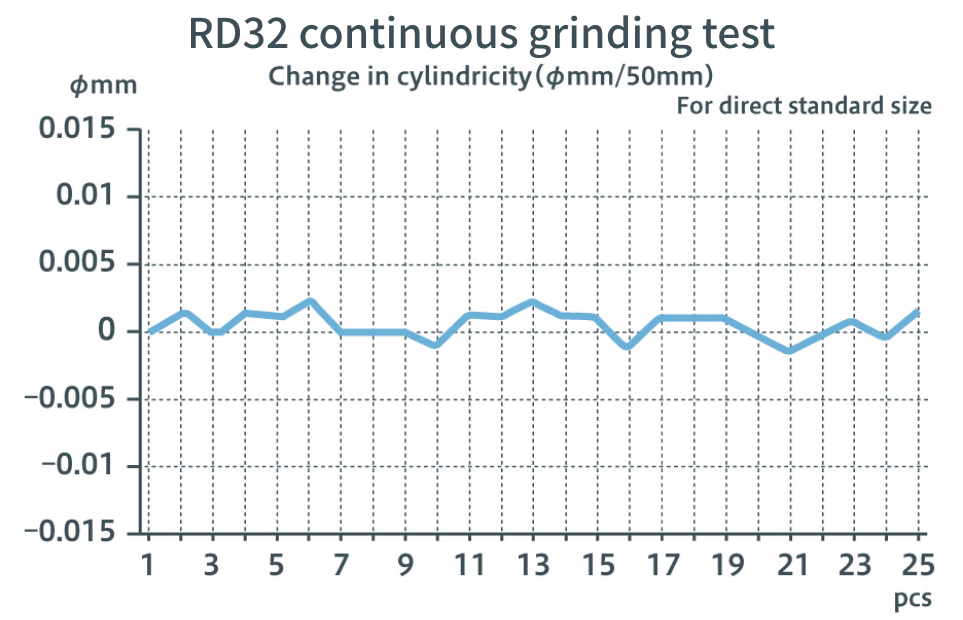

RD32

- Grinding wheel slide type

angular/straight - Swing (mm)

φ320 - Center distance (mm)

500/1,000 - Max. grinding diameter (mm)

φ300 - Max. grinding weight (kg)

150

Features

The stable griding is possible for various grinding needs.

- It achieves high precision grinding with improving the precision and the rigidity of its mechanical structure of the spindle and feed shaft etc., and setting the minimum command unit for feed control to ⌀0.1 μm.

- The grinding repeatability is so stable that a change in cylindricity is just ⌀3 μm/50 mm (RD23/RD32) after 1 hour even from a cold start.

Specifications

| Item / Model | RD23 | RD32 | ||

|---|---|---|---|---|

| Capability | Grinding wheel slide type | Angular/straight | Angular/straight | |

| Swing (mm) | ⌀230 | ⌀320 | ||

| Center distance (mm) | 350 | 500 | 1,000 | |

| Max. grinding diameter (mm) | ⌀150 | ⌀300 | ||

| Max. grinding weight (kg) | 80 | 150 | ||

| Grinding wheel | Grinding wheel outer diameter (mm) | ⌀405 (⌀455) | ⌀455(⌀510) | |

| Inner diameter × width (mm) | ⌀127X50(75) | ⌀152.4 X75 (120) | ||

| Peripheral speed (m/s) | 45(60) | 45(60) | ||

| Grinding wheel stand (X-axis) | Rapid traverse rate (m/min) | ⌀20 | ⌀20 | |

| Grinding feedrate (mm/min) | ⌀0.001 to 20,000 | ⌀0.001 to 20,000 | ||

| Command unit (µm) | ⌀0.1 | ⌀0.1 | ||

| Table (Z-axis) | Rapid traverse rate (m/min) | 20 | 20 | |

| Traverse speed (mm/min) | 0.001 to 20,000 | 0.001 to 20,000 | ||

| Command unit (µm) | 0.1 | 0.1 | ||

| Head stock | Rotation speed (min-1) | 8 to 800 | 10 to 500 | |

| Number of conversions | Continuous | Continuous | ||

| Center taper | MT No. 4 | MT No. 4 | ||

| Tailstock | Stroke (mm) | 150 (including normal stroke 35) | 50 (including normal stroke 50) | |

| Clamp method | Spring | Spring | ||

| Forward/backward method | Manual lever | Manual lever | ||

| Center taper | MT No. 4 | MT No. 4 | ||

| Taper fine adjustment stroke (mm) | ±0.125 | ±0.125 | ||

| Dresser | Single point dresser holder | Single point dresser holder | ||

| Motor | Grinding wheel motor (kW) | 3.7 (5.5) | 5.5 (7.5) | |

| Spindle motor (kW) | 1.6 | 3.0 | ||

| Power capacity (kVA) | 12[B] 17[H] | 16[B] 26[H] | ||

| Floor to work center height (mm) | 1,000 | 1,105 | ||

| Machine weight (kg) | 3,000 | 4,500 | 5,000 | |

Remarks: () is optional [B] is for ball bearings [H] is for static pressure bearings