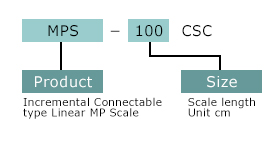

Precision position detectors MP SCALE|Linear position detector|Connected type of linear position detector

MPS-C series

The handling companies : Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

Features

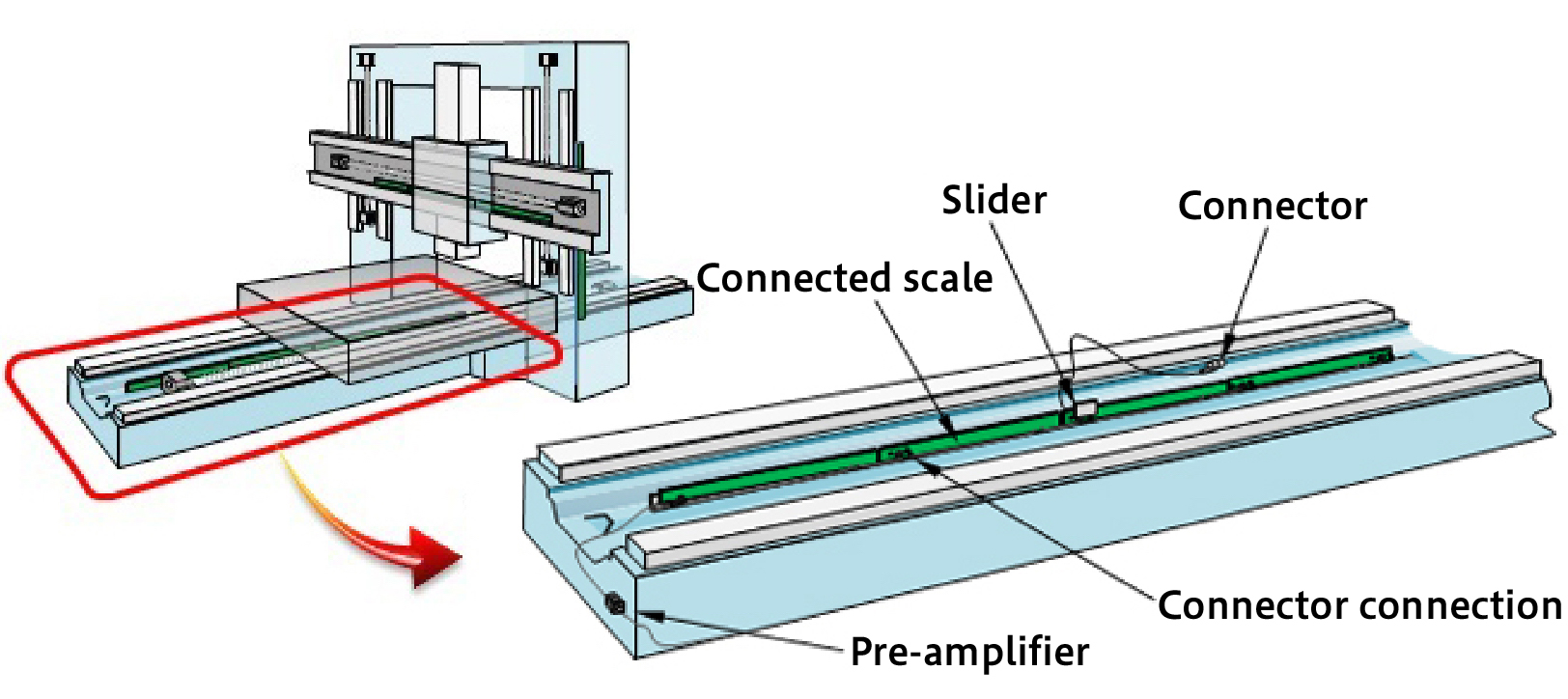

Easy connection, because of connector.

Water-proof for coolant is improved because no electrical exposed part.

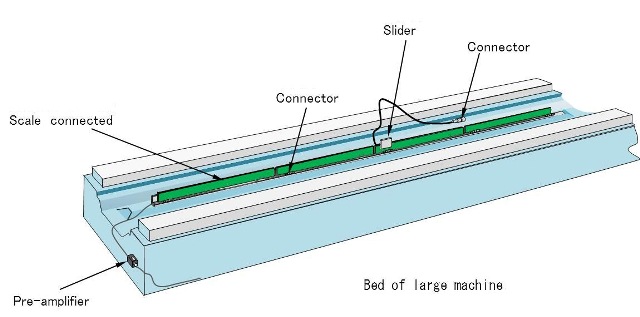

Application

Position detection for linear axis of large machine

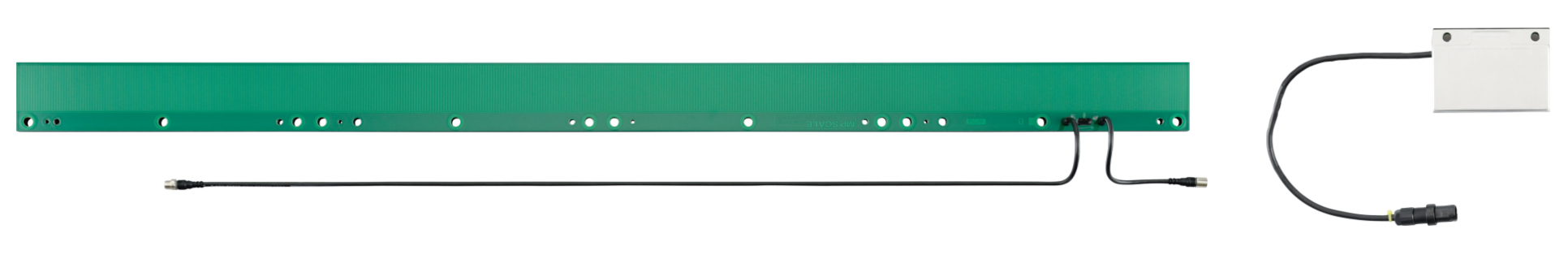

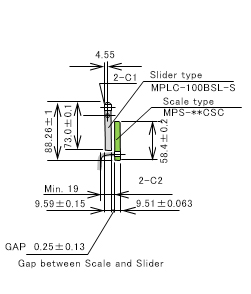

Scale Type

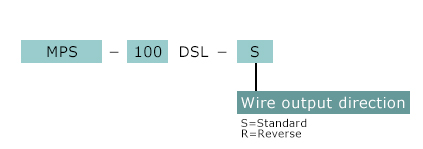

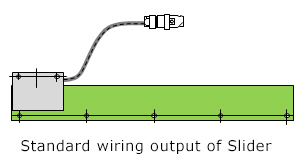

Slider Type

Specifications

| Scale | |||||

|---|---|---|---|---|---|

| Scale type | Effective stroke | Accuracy ※1 | Length | Weight ※2 | |

| Scale | MPS-25CSC | 250mm×n-100mm | 2.5μm | 250mm | 1.1kg |

| MPS-50CSC | 500mm×n-100mm | 4.0μm | 500mm | 2.1kg | |

| MPS-75CSC | 750mm×n-100mm | 4.5μm | 750mm | 3.2kg | |

| MPS-100CSC | 1000mm×n-100mm | 5.0μm | 1000mm | 4.2kg | |

| Slider | MPS-100DSL | 101.6mm | 0.5kg | ||

Scale Stroke

The stroke is value which subtracted 100mm from the sum total of the length of selected Scales.

Ex)When MPS-100CSC are 3 pieces and MPS-75CSC is 1 piece, Scale stroke is,

1000mm × 3 pieces + 750mm - 100mm = 3650mm

| Applicable A/D converter | ||||

|---|---|---|---|---|

| NC | Type | Output signal | Resolution | Max. speed |

| FANUC | ADB-K64FM ADB-20J64 |

Serial I/F | 0.01μm | 1800m/min |

| Mitsubishi CNC | 0.05μm | |||

| Various equipment | ADB-20J10 | Digital A/B/Z phase | 0.1μm | 80m/min |

| ADB-20J14 ※3 | ||||

| ADB-20J30 | Analog A/B, digital Z phase | 10μm/1 cycle SIN wave |

||

※1:Position error shows peak-to-peak. Interpolation error (Error within Scale 1 pitch) is not included.

※2:Wiring is not included in weight.

※3: When Scale stroke length is 4m or more, ADB-20J64 or ADB-20J14 are chosen.

Mounting Example

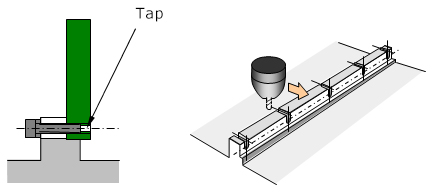

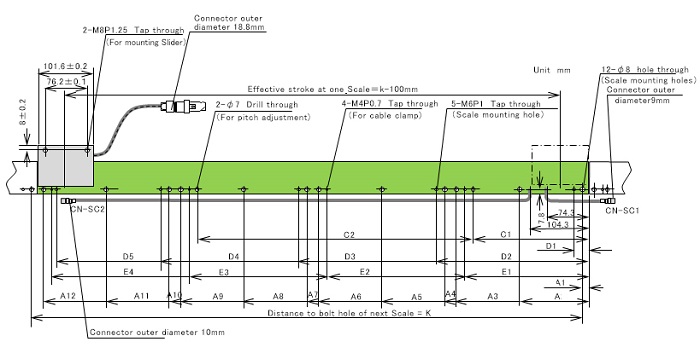

Mounting holes of pushing method

Scale is mounted using the holes of A1 to A12 in below drawing. Please prepare Tap holes at the mounted side.

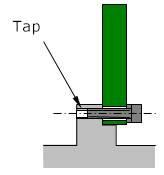

Mounting tap holes of pulling method

Scale is mounted using the tap holes of D1 to D5 in below drawing. In this case, the mounting part is performed the slot machining, as shown in below figure

Dimensions

Unit : mm

| Type | K Distance to next Scale |

Length L | Attached cable length |

Existence of connector mounted |

|

|---|---|---|---|---|---|

| Scale | MPS-25CSC | 250 | 249.85 | Connectors attached to both ends. |

|

| MPS-50CSC | 500 | 499.85 | |||

| MPS-75CSC | 750 | 749.85 | |||

| MPS-100CSC | 1000 | 999.85 | |||

| Slider | MPS-100DSL | 1.5m | Attached | ||

| Tolerance | +0.05~-0 | ||||

| Holes mounting from pattern side | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of mounting holes |

A12 | A11 | A10 | A9 | A8 | A7 | A6 | A5 | A4 | A3 | A2 | A1 | |

| Scale | 3 | 239.2 | 124.9 | 10.6 | |||||||||

| 6 | 489.2 | 374.9 | 260.6 | 239.2 | 124.9 | 10.6 | |||||||

| 9 | 739.2 | 624.9 | 510.6 | 489.2 | 374.9 | 260.6 | 239.2 | 124.9 | 10.6 | ||||

| 12 | 989.2 | 874.9 | 760.6 | 739.2 | 624.9 | 510.6 | 489.2 | 374.9 | 260.6 | 239.2 | 124.9 | 10.6 | |

| Slider | 2 | ||||||||||||

| Tolerance | ±0.1 | ||||||||||||

| Type | For cable clamp | Number of holes |

For cable clamp | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of holes |

E4 | E3 | E2 | E1 | Number of mounting holes |

D5 | D4 | D3 | D2 | D1 | Number of holes |

C2 | C1 | ||

| Scale | MPS-25CSC | 1 | 223.4 | 2 | 195 | 25 | 1 | 209 | |||||||

| MPS-50CSC | 2 | 250 | 223.4 | 3 | 460 | 275 | 25 | 1 | 209 | ||||||

| MPS-75CSC | 3 | 250 | 250 | 223.4 | 4 | 695 | 525 | 275 | 25 | 2 | 500 | 209 | |||

| MPS-100CSC | 4 | 250 | 250 | 250 | 223.4 | 5 | 965 | 775 | 525 | 275 | 25 | 2 | 500 | 209 | |

At designing mounting, Please require and refer to the Scale mounting drawing.