Precision position detectors MP SCALE|Rotary angle detector|General of rotary angle detector

General of rotary angle detector

The handling companies : Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

- Environmental conditions

- Purpose and selection of rotary mp scale

- Mounting example of rotary mp scale

- Contact

Environmental conditions

The environmental conditions of Rotary MP Scale are as follows.

| Items | Conditions |

|---|---|

| Ambient temperature | -10 to 70 deg. Note1: |

| Relative humidity | Less than 95% |

| Vibration resistance | Displacement amplitude 1.5mm, 10 to 55Hz |

| Impact resistance | 55G 11msec |

| IP code | IP67 Equivalent |

| Proof of coolant water, coolant oil and dew condensation | Although it does not consider using MP scale in the situation of immersed in those, if immersed at short time, the function of Scale operates without problem. However, if they are poured for a long time, the rust may occur on Scale blank, and fault may occur. |

| Foreign material | If aluminum foil is not striped or the pattern is not injured even if the foreign materials enter between Rotor and Stator, Scale operates without problem. However, since cutting chip becomes the factor which gives the crack, please protect with the cover etc. |

Note1: In MPZA series, the ambient temperature is 0°C~60°C.

Purpose and Selection of Rotary MP SCALE

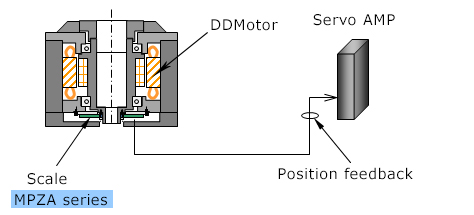

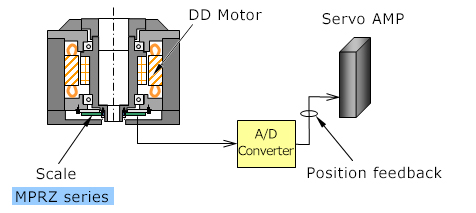

For direct drive motor, absolute

and

MPZA series or MPRZ series Scales which detects the absolute data with high speed and high precision are selected for DD motor.

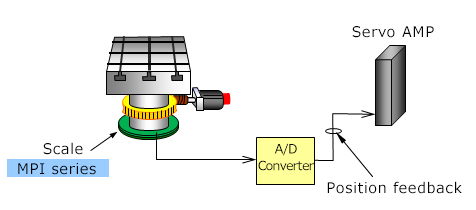

For using reduction mechanism, incremental MPI series.

MPI series scales are suitable for position detection of rotating and tilting axis for a rotary table.

MPI series Scale on which pre-amplifier is built into rotary Scale is allowing for better space efficiency.

Possible to detect positioning with high speed and high accuracy.

MPZA series and MPRZ series can also be used for the machine with reduction mechanism.

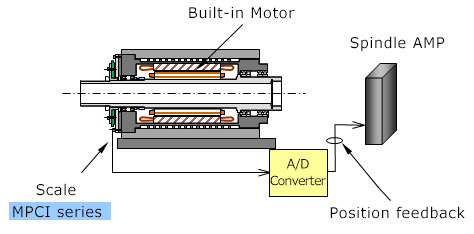

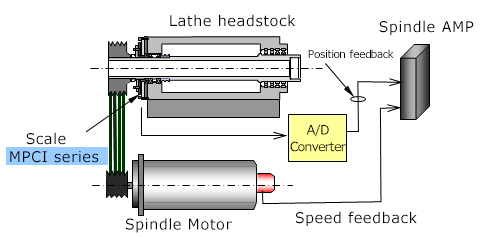

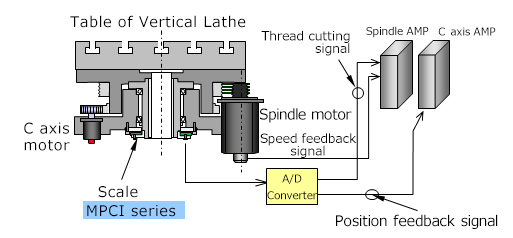

For Spindle speed and C axis control, MPCI series with One-revolution detection

MPCI series Scale outputs one Z phase signal per revolution. Possible to detect both C axis position and speed control with high speed and high accuracy.

MPCI Scale is most suitable for the rotation control and C axis control of Lathe Spindle at both built-in Spindle and independent Spindle motor.

In case of C axis independent feed motor, when ADB-20J16 is used, following (1) and (2) outputs are possible with one Scale.

(1) 900,000 or 90,000 pulses for position index. (Position feedback)

(2) 9,000 or 1,024 pulses for thread cutting and orientation

Mounting example of Rotary MP Scale

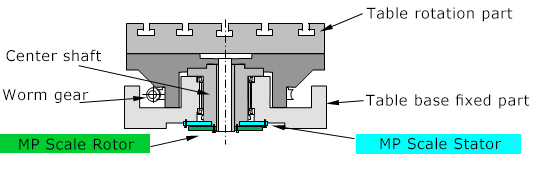

Stator of Rotary MP Scale is mounted on the fixed part, and Rotor is mounted on the rotation part.

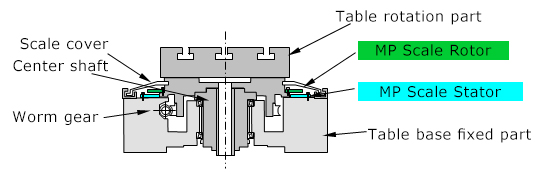

Example of mounting Scale at the bottom of Rotary table (Center shaft rotating)

Since there is no fixed part in the upper part of Rotary table generally, the Scale mounting place is selected at the bottom of Rotary table.

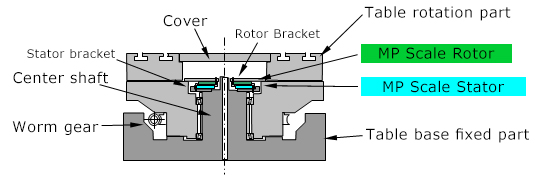

Example of mounting at the upper part of Rotary table (Center shaft rotating)

By selecting large inner diameter MP scale, MP Scale can be arranged on the outside of the rotary table. The maximum inner diameter is φ 240mm at MPCI-24072A.)

Example of mounting at the upper part of Rotary table (Fixed center shaft)

When the center shaft of the rotary table is fixed, the stationary part is near the table upper surface, and Scale with the even small inner diameter can be mounted at the upper part of the table.

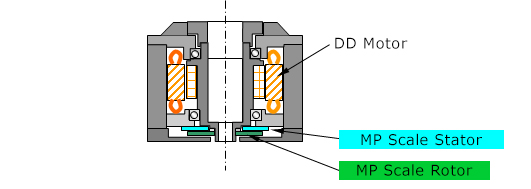

Example of the rotary table with the direct drive motor(DD motor)

Because there is no fixed part in the rotary table upper part in the case of DD motor generally, the Scale mounting place is selected the table bottom. The big hollow of Scale fits with the center hole of DD motor.

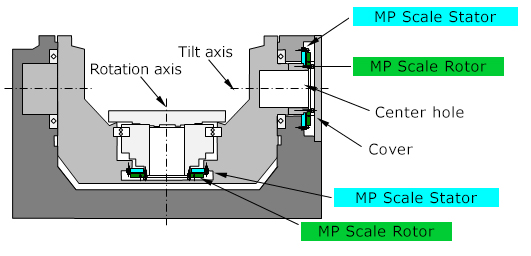

Example of 5 axis Rotary table

In case of tilt axis of 5 axis Rotary table, the mounting position is selected at the outside of the drive shaft, and in case of rotation axis, the mounting position is selected at the lower part of the table.

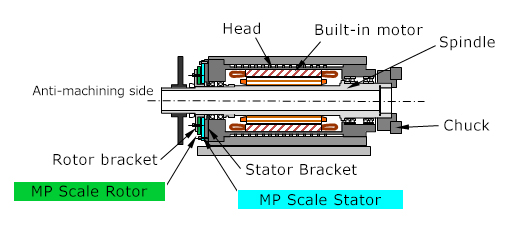

Example of Lathe Spindle

Generally the machining side with the chuck cannot ensure the mounting space, thus Scale is mounted on the anti-machining side.

The other reason of selecting the anti-machining side is the coolant water.