Machine Tools|Large Machines|Horizontal Boring Mills

Table Type Horizontal Boring Mills MHT Series/ MAF-EⅡ Series

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

The MHT/MAF-EII series raises a level of production in a wide range of machining operations from high-speed/heavy- duty cutting of large workpieces to die/precision parts manufacturing.

MHT series

MHT1416

Boring spindle diameter (mm)

φ130

Table

Working area (mm)

1,400 × 1,600

Indexing

0.001 degree indexing (opt. 0.0001 degree indexing, cutting feed B axis)

Loading capacity (kg)

8,000 (opt. 12,000)

MHT1618

Boring spindle diameter (mm)

φ130

Table

Working area (mm)

1,600 × 1,800

Indexing

0.001 degree indexing (opt. 0.0001 degree indexing, cutting feed B axis)

Loading capacity (kg)

8,000 (opt. 12,000)

MAF-E II series

MAF130EⅡ

Boring spindle diameter (mm)

φ130

Table

Working area (mm)

1,800 × 2,000

2,000 × 2,200

2,000 × 2,500

Indexing

0.0001 degree indexing (opt. cutting feed B axis)

Loading capacity (kg)

20,000

Features

High-rigidity structure that supports powerful machining MHT series

- (1)Column

It adopts a center head type box column that achieves high rigidity and thermal stability. Deformation due to cutting force during processing is minimized thanks to a thermo-symmetric structure in which the spindle is centrally located, therefore that machining accuracy is stabilized. - (2)Table

The table thickness has been increased by 30% compared to the conventional model. Boasting high rigidity, it ensures safety and high productivity even when loading large workpieces or performing heavy duty cutting. - (3)Bed

It adopts a T-shaped structure that strongly fastens the table bed and column bed to achieve the machine's accuracy in longer period.

The MAF-EII series are designed to machine larger size workpieces with higher accuracy.

The best-in-class spindle performance

It supports various types of workpiece machining such as high-speed machining with a small-diameter drill, low-speed high-output machining with a large-diameter milling tool, and high-torque machining with large-diameter boring.

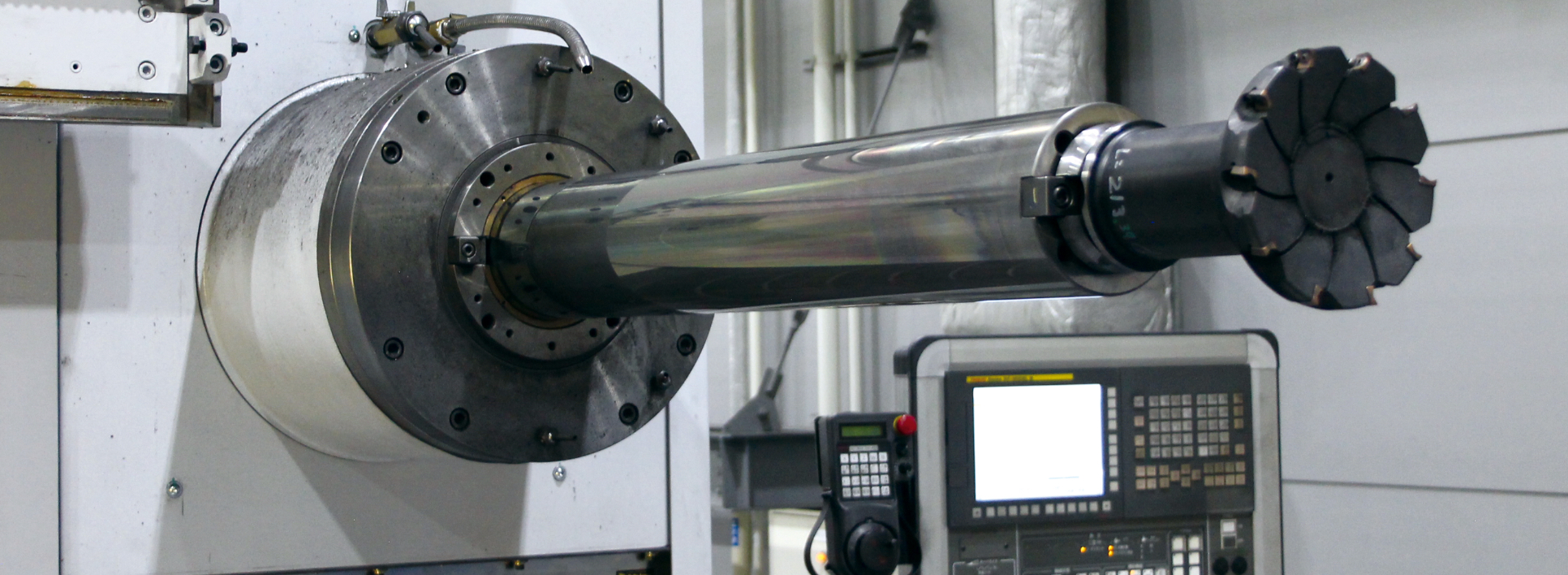

The extension of the boring spindle is 800 mm, the best in its class

Good accessibility to workpieces, ideal for deep hole boring

Quick axis movement can shorten non-cutting time

Rapid traverse rate: X, Y, Z-axis: 15 m/min, W-axis: 10 m/min, B-axis: 500 deg./min

Specifications

| Item / Model | MHT1416 | MHT1618 | MAF130EⅡ | ||||

|---|---|---|---|---|---|---|---|

| Boring spindle diameter (mm) | ⌀130 | ⌀130 | |||||

| Table | Working area (mm) | 1,400 × 1,600 | 1,600 × 1,800 | 1,800 × 2,000 | 2,000 × 2,200 | 2,000 × 2,500 | |

| Indexing | Indexing at every 0.001 deg. (opt. indexing at every 0.0001 deg., cutting feed B axis) |

Indexing at every 0.0001 deg. (opt. cutting feed B axis) |

|||||

| Loading capacity (kg) | 8,000 (opt. 12,000) | 20,000 | |||||

| Axis travel | Table, horizontal X-axis (mm) | 2,000 (opt. 3,000) | 3,000 | ||||

| Spindle head, vertical Y-axis (mm) |

1,500 (opt. 2,000) | 2,000 (opt. 2,500) | 2,300 | ||||

| Column, in/out Z-axis (mm) | 1,300 | 1,600 | |||||

| Boring spindle, in/out W-axis (mm) | 500 | 800 | |||||

| Spindle head | Spindle speed (min-1) | 10 to 2,500 (opt. 15 to 4,000) | 5 to 2,500 | ||||

| Spindle motor output (continuous/30 min) (kW) | VAC 22/26 (opt. 30/37) |

VAC 30/37 | |||||

| ATC tool storage capacity (pcs) | 40 (opt. 80, 120) | 50 (opt. 80, 100) | |||||

| Machine weight (kg) | 27,000 | 29,000 | 45,000 | 45,500 | 46,000 | ||