Machine Tools|Special Purpose Machines|Special Purpose Machines

Special Purpose Machines

The companies handling the product:Nidec Machine Tool Corporation

- Contact information for product inquiry

- Contact Us

We can offer special purpose machines which are optimized for various types of customer needs in the field such as aircraft and industrial machinery and so on.

For aircraft industry

5-axis vertical precision milling machine MVR30S-5H

The 5-axis milling processing with high-power main spindle

Aluminum aircraft parts can be processed with this one unit from rough machining to final machining with this one unit. It achieves reliable and efficient processing with a high-speed, high-power spindle and simultaneous 5-axis control. In addition,it fully responds to the needs of aircraft components manufacturing, with such as providing a large table that can comfortably handle large parts, and option settings developed based on our unique know-how.

| Table work surface (mm) | W 1,800 × L 5,000 |

|---|---|

| Spindle speed (min-1) | 200 to 15,000 |

| Spindle motor (kW) | 37/68 |

| Ram size (mm) | □350 |

| Spindle swing (B-axis) | −30° to +105° |

| Spindle swivel (C-axis) | ±190° |

| Stroke (X-Y-Z) (mm) | 6,200-2,490-626 |

For power generation industry

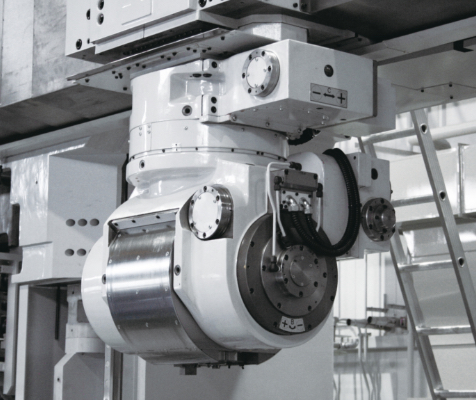

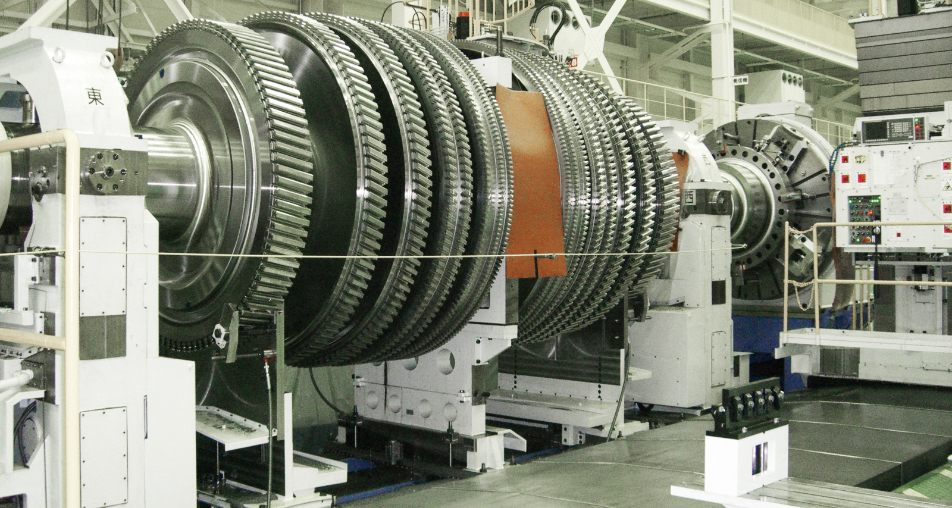

Side entry blade groove cutting machine

High efficiency with the four-head configuration

It machines blade grooves of turbine rotors with dedicated cutters. The machining units are arranged facing each other so as to surround the rotor (up to 4 units), and it is possible to process 4 grooves at the same time. The workpiece (center)bed is equipped with a dividing head and a static bearing stand. And we can also supply these dedicated cutters.

| Work specifications size (mm) | ⌀3,600 × 13,600 |

|---|---|

| Workpiece specifications weight (ton) | 300 |

| Spindle speed (min-1) | 20 to 1,500 |

| Spindle motor (kW) | 22/30 |

| Max. spindle torque (Nm) | 1,460 |

| Min. head-to-head distance (mm) | 1,200 |

| Stroke (X-Y-Z-W) (mm) | 10,000-1,300-450-900 |

For construction machinery

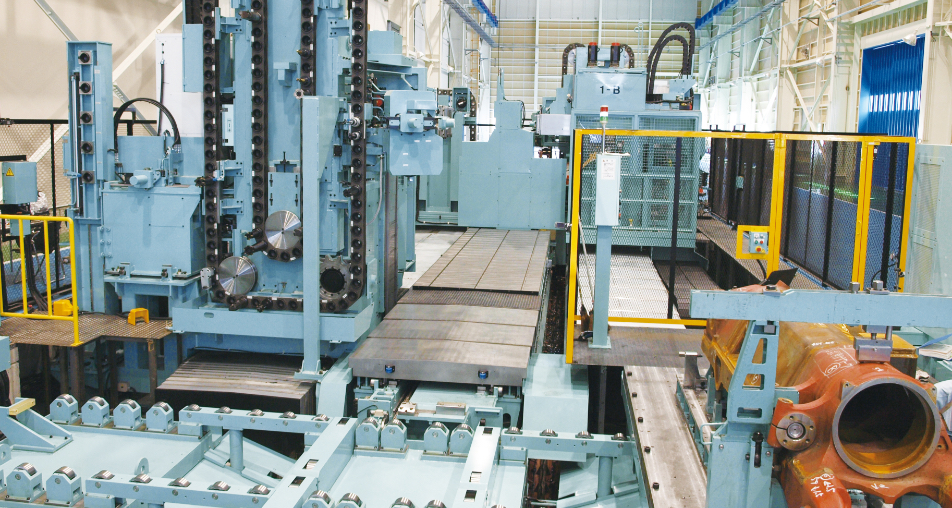

Large-frame machine

One-chuck machining in all orientations

The purpose is to process long and box-shaped pieces with high efficiency. This floor-type horizontal boring and milling machine has a 650 mm extendable boring spindle and processes using a combination of a rotary table and a floor plate. The machining units are arranged facing each other so as to surround the workpiece, and it is possible to process up to 4 locations at the same time. With APC, workpiece set-up is possible during processing.

| Pallet size (mm) | 5,000 × 1,500 |

|---|---|

| Loading capacity (ton) | 10 |

| Spindle speed (min-1) | 20 to 6,000 |

| Spindle motor (kW) | 27/37 |

| Ram size (mm) | □400 |

| Stroke (X-Y-Z) (mm) | 6,000-1,800-700 |