MACH11 HOB

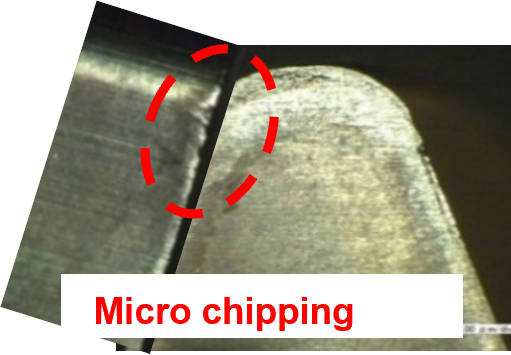

This dissolution HSS provides excellent resistance against, heat, wear, and chipping.

Characteristics

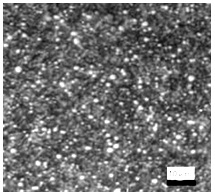

- 1.The fine particle with uniform placement enhances the chipping resistance.

- 2.Strengthening of substrate binding with salt heat treatment performs the resistance against chipping and wear.

- 3.The optimum heat treatment conditions leads the resistance against heat and wear.

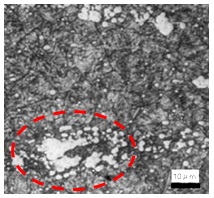

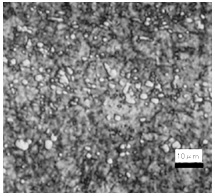

| Dissolution HSS | MACH11 | Powder HSS |

|---|---|---|

|  |  |

| Forming coarse carbide particles over 10μm attracts severe chipping when the particles drop off. | Forming the finest carbide particles uniformly as 10 μm or less. | The finest carbide particles as (3 μm or less) are uniformly formed and excellent in chipping resistance however it has lower wear resistance than Dissolution HSS. |

Cutting result

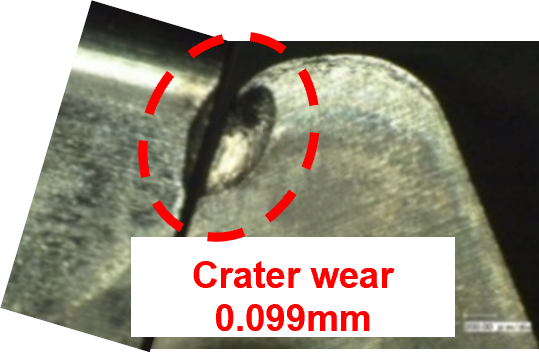

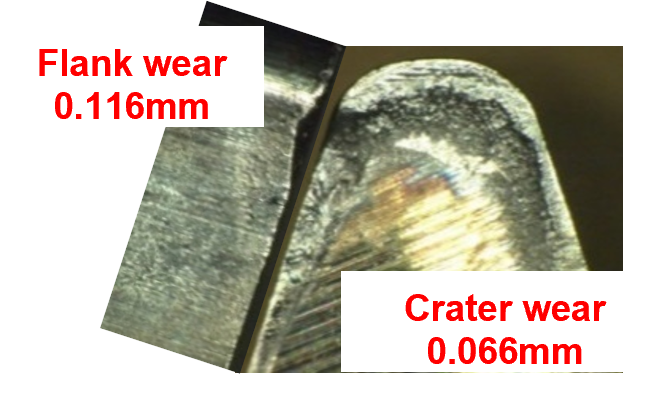

Result 1 / Recoat use

【Part dimensions】

- m2.25 PA17.5°23°LH

- NT46 SCM415

【Hob dimensions】

- φ75×150L 3starts

- 16flutes

【Cutting condition】

- Cut speed 300m⁄min

- Axial feed 2.4mm⁄rev

- Cut length 40m(Non shift)

- Climb,Dry cut

| MACH7/SuperDryIII | MACH11/SuperDryIII |

|---|---|

|  |

|  |

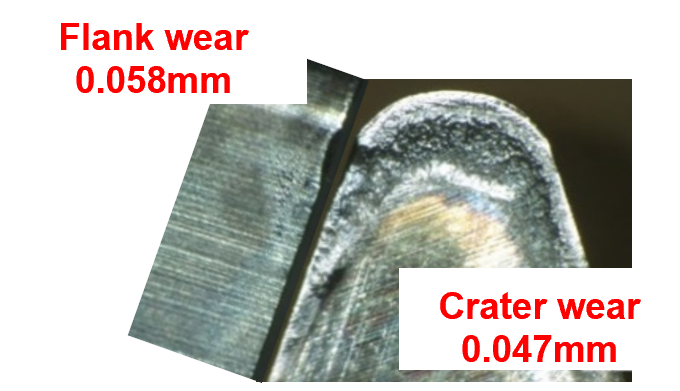

Result 2 / Non Recoat use

【Part dimensions】

- m2.25 PA17.5°23°LH

- NT52 SCM415

【Hob dimensions】

- φ75×150L 3starts

- 16flutes

【Cutting condition】

- Cut speed 150m⁄min

- Axial feed 2.4mm⁄rev

- Cut length 50m(Non shift)

- Climb,Dry cut

| MACH7/SuperDryIII | MACH11/SuperDryIII |

|---|---|

|  |