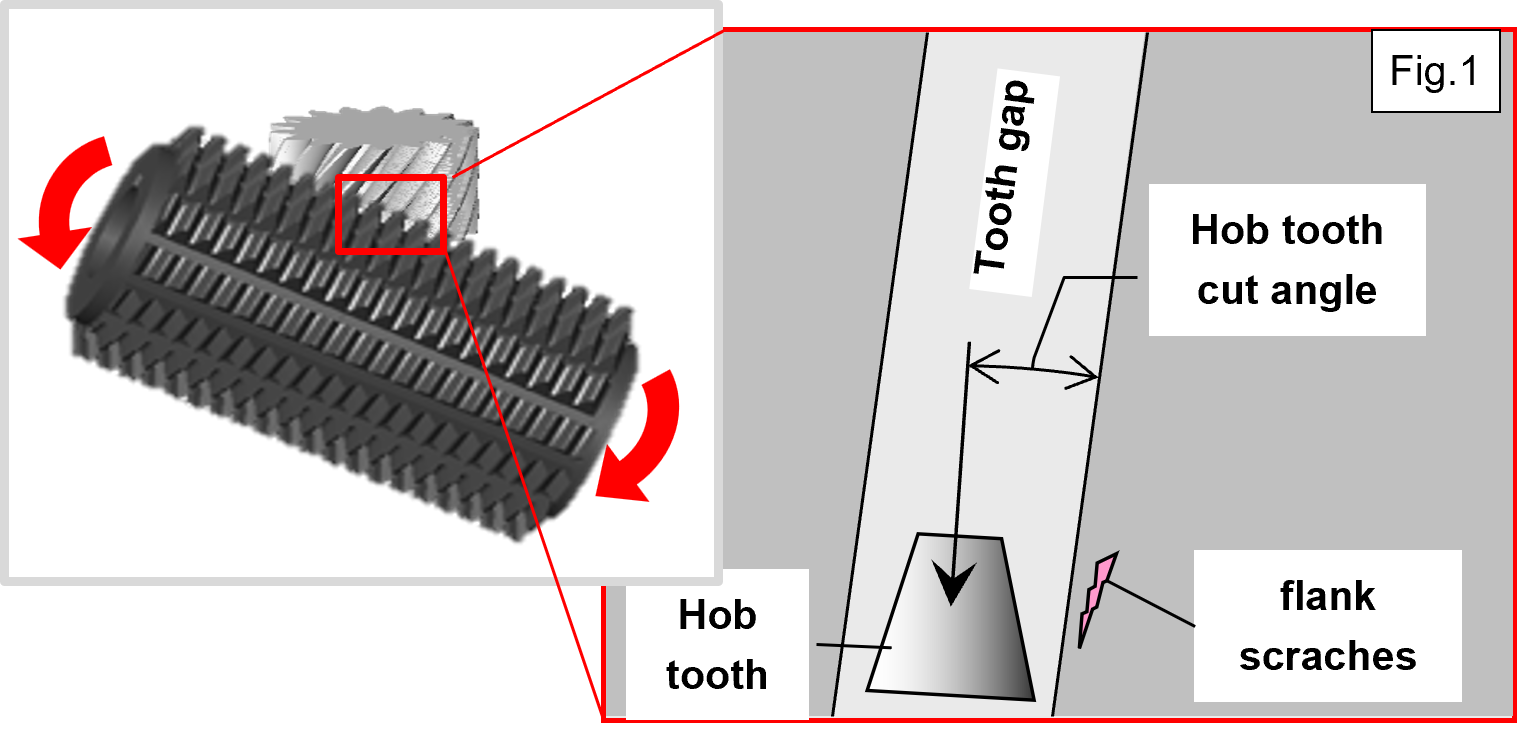

Influence on tooth thickness and tip chamfer caused by adjusting hob set angle in order to eliminate scratch mark on the flank

In dry hob cutting , scuffs and scratches may occur on the tooth surface of the gear,

whereas in wet cutting a large amount of cutting oil removes chips and suppresses

the occurrence of scuffs and scratches.

In that case, the reducing hob set angle may be able to affect to suppress scuffs and scratches.

On the other hand, due to smaller set angle, the tooth thickness of the gear becomes thinner.

And if you adjust the radial cut depth smaller to get the tooththickess thicker,

the tip chamfer on the tooth will decrease.

As a reference, we summarise the influence on tooth thickness and tip chamfer

against the hob set angle error.

1) Adjusting the hob set angle

2) Formula for calculating gear tooth thickness reduction (Theoretic)

- For Spur gears △W = mn * { sin2γ * (⊿ε)2 / (2*tanαn) } * ( g / sin3γ + Z )

- For helical gears △W = mn * { sin2γ * (⊿ε)2 / (2*tanαn) } * ( g / sin3γ + (Z/cos3β) )

- △W :Reduced amount of part tooth thickness Z:Part NT β:Part Helix angle

- mn :Hob module(Normal) αn :Hob pressure angle γ :hob lead angle ⊿ε:Hob lead angle error

- g : Hob Nos. of starts

3) Formula for calculating gear tip semi-topping reduction (Theoretic)

- In case of reducing radial feed to adjust tooth thickness,

- the reduced amount of tip semitopping can be calculated as follows,

- △C = △W / (2 * tanαn)

- △C :Reduced amount of tip semi-topping (Radial) αn :Hob pressure angle