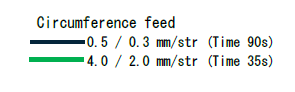

High speed shaping cut - Large circumference feed -

Conventional feed

Cutting load is concentrated at cutter tooth tip.

The cutter flank wear at trailing side tends to increase due to thinner longer chips.

Large circumference feed

The chips are generated thicker than Conventional feed.

【Part dimensions】

- Module 2.25 NT27

- Helix angle 31.5

- Width 15mm

- Material SCM415

【Cutter dimensions】

- NT57

- Material MAC-B(HSS)

- With PVD COAT

【Cutting conditions】

- Stroke 800/1200/min

- Radial feed 0.02/0.01mm/str

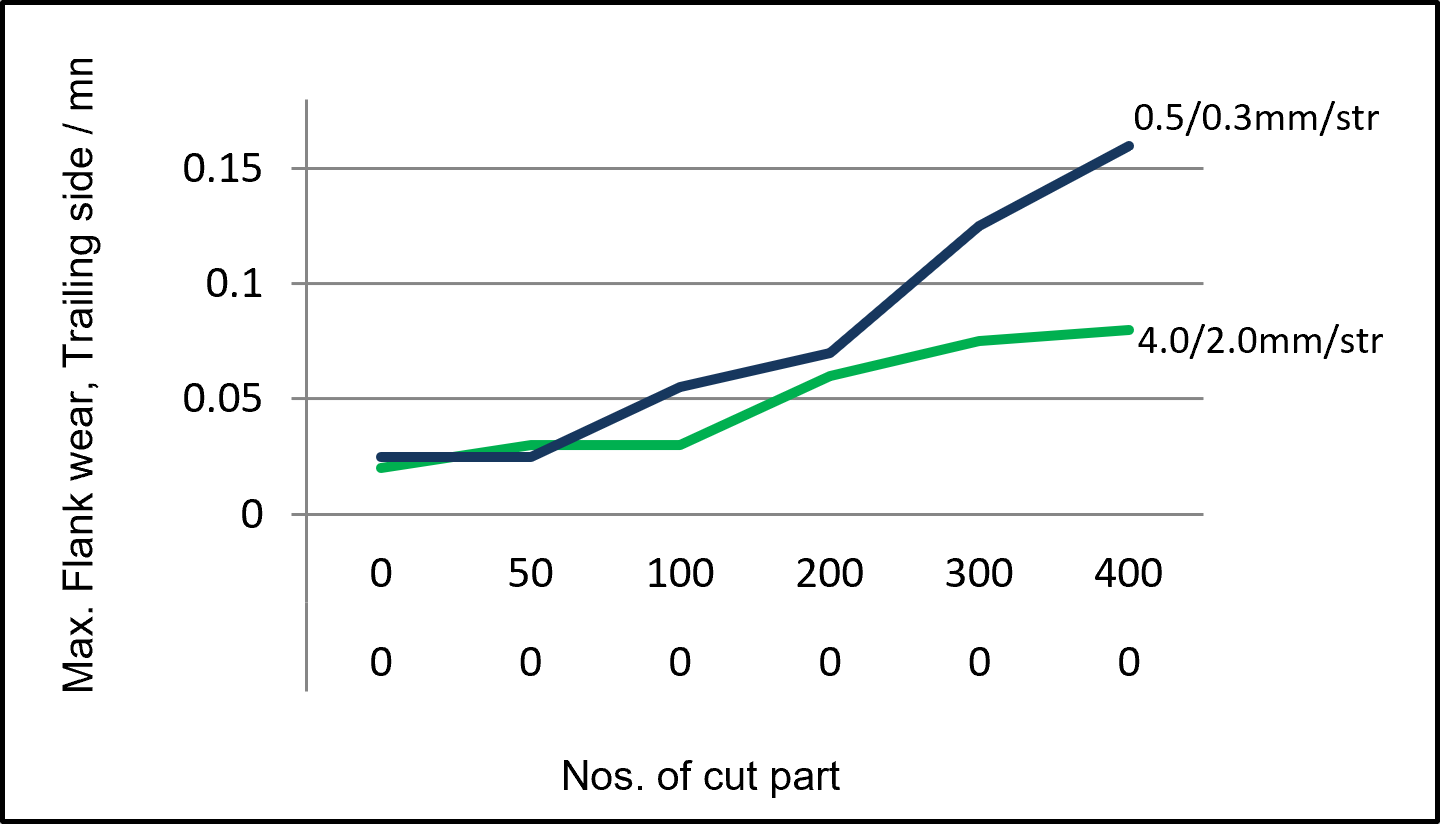

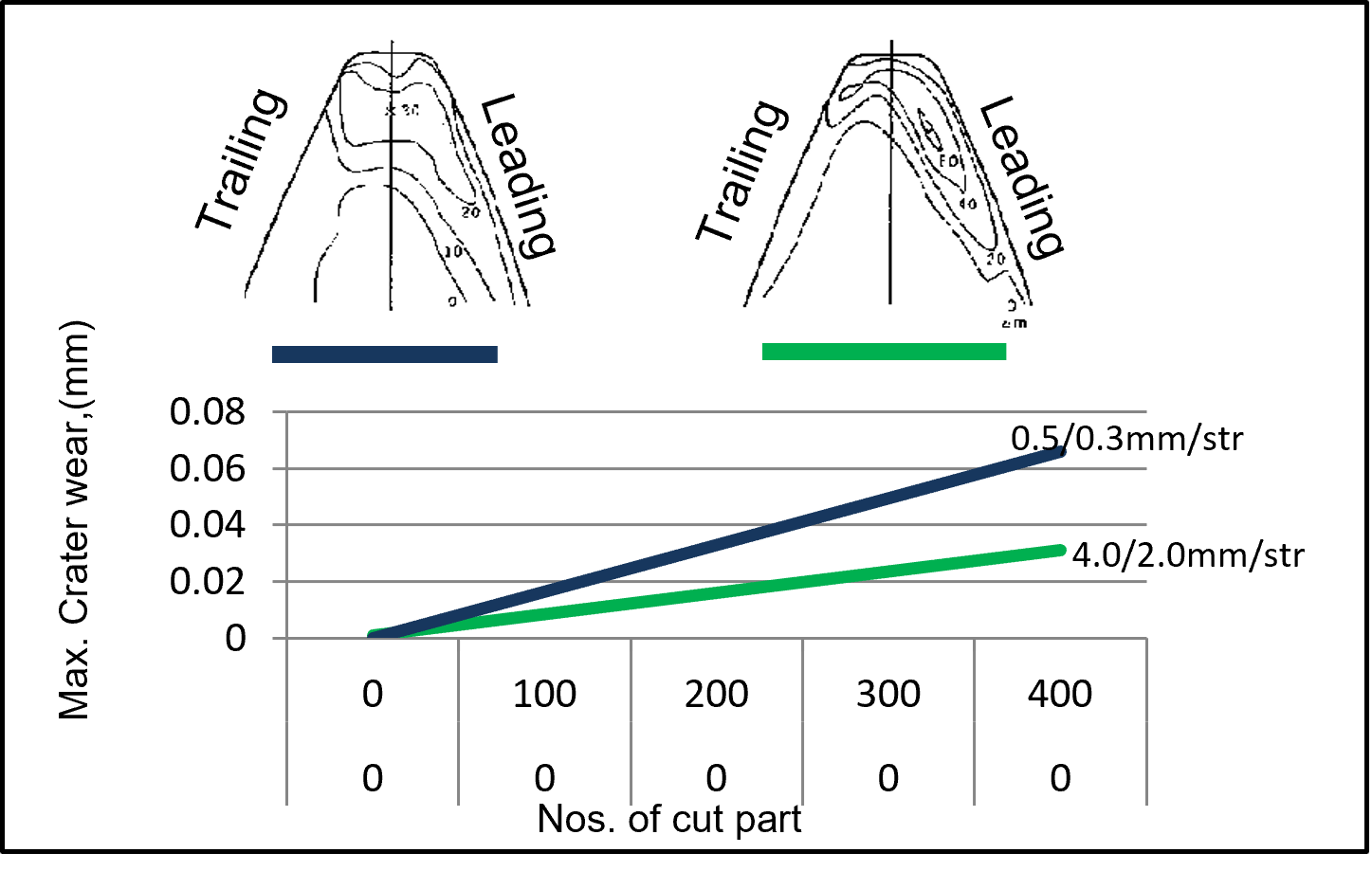

As graphs are shown,both flank wear and crater wear with the larger circumference feed are smaller than the ones with smaller feed.

NOTE: In case of which shaping is the final process for gears and the cutting surface roughness doesn't

meet the accuracy, the feed rate should be smaller. For those which final process is shaving or grinding,

the surface roughness is usually out of scope on the shaping process.