Dry hobbing / countermeasure for scratch

CASE 1 / Caused by chips immediately after generation

- Scratches occur at the same position on all tooth surfaces.

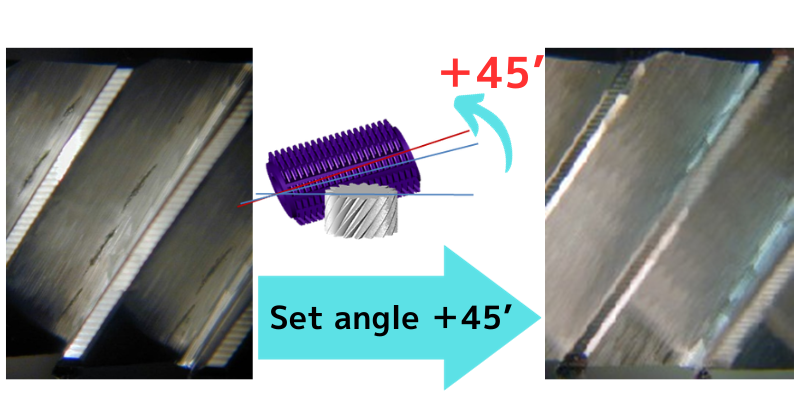

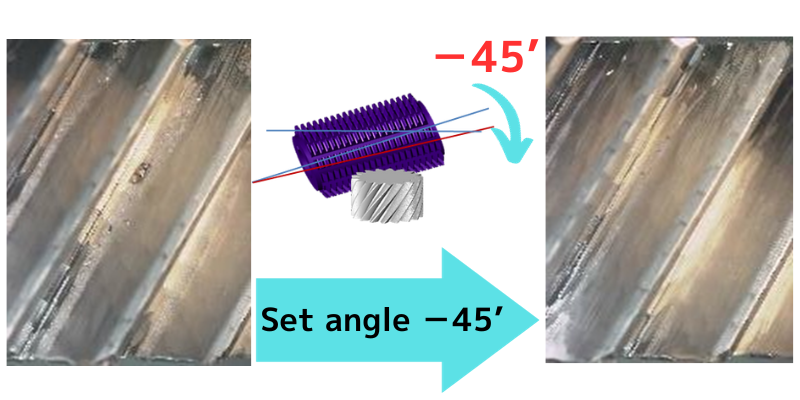

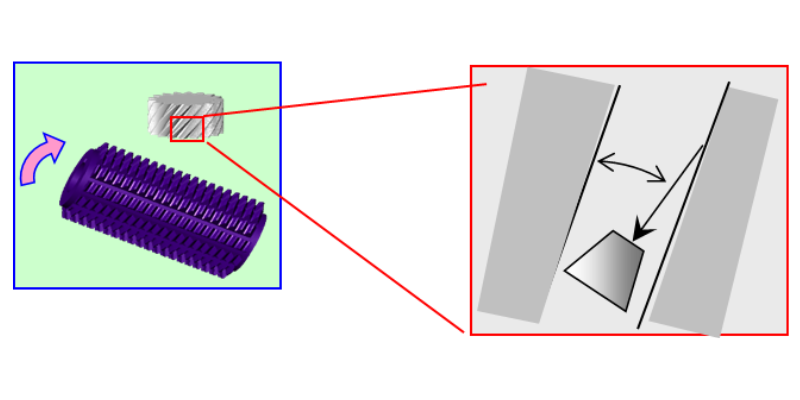

Change the hob set angle in the range of about 15'to 1 ° (Fig 1 below) in the direction in which the approach angle of the hob cutting edge on the damaged tooth flank side larger (see Fig. 2 below).

CASE 2 / Caused by the chips that have already been cut off and came into the cutting point again.

- There are scratched and non-scratched teeth.

- The chip may get welded on the tooth flank.

Change the mounting angle in the range of about 15'to 1 ° (Fig 1. below) in the direction in which the approach angle of the hob cutting edge on the damaged tooth flank side becomes smaller.Also, keep the direction of the air nozzle as close to the cutting point as possible to keep chips away from the cutting point.

Fig 1. By set angle adjustment,Part tooth thickness decreases.

| Angle | Amount |

|---|---|

| 15′ | 2μm |

| 30′ | 8μm |

| 45′ | 18μm |

| 1° | 32μm |

(m2,α20°,HOB ODφ80)