Inspection method of resharpening accuracy for hobs - Top rake of cutting face

In order to use hobs while maintaining accuracy and life,

it must have the correct resharpening accuracy.

Therefore, it is important to evaluate the hob accuracy after resharpening.

The measurement method is described in JIS B4355, test number 5-7,

However it seems a little abstract and difficult to understand.

So we introduce a practical method that users can measure without a specialised measuring device.

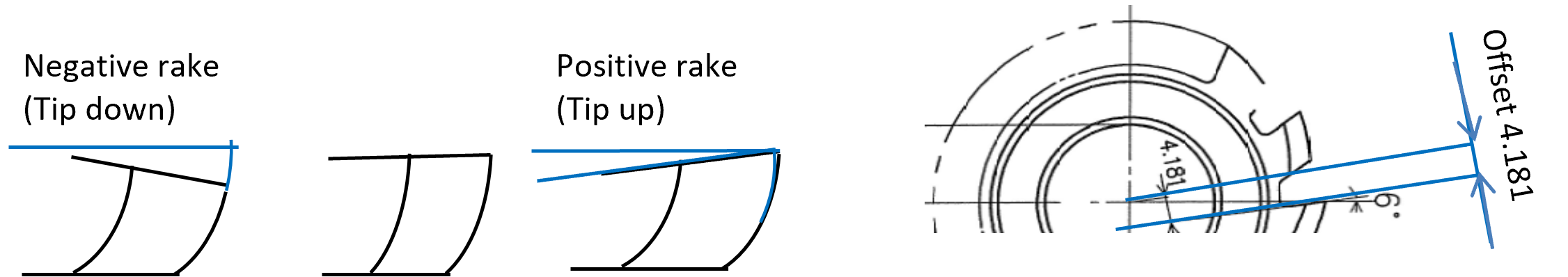

Form and position of cutting face

■Devices

- 1.Bench Center 1set

- 2.Straight mandrel 1set

- 3.Dial test indicator (Lever type)

with magnetic stand 1set

(Min scale 0.002mm) 1set - 4.Gauge block 1pc

- 5.Micrometer 1pc

How to measure

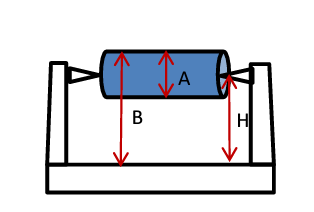

- 1.Mount the hob on the straight mandrel and set the mandrel up on the bench center.

- 2.Calculate the center point height of mandrel

- 1.Measure the mandrel outer diameter by the micrometer / A

- 2.Set the mandrell up on the bench center.

- 3.Measure the height of mandrel. / B

- 4.Calculate the center point height of mandrel. / H

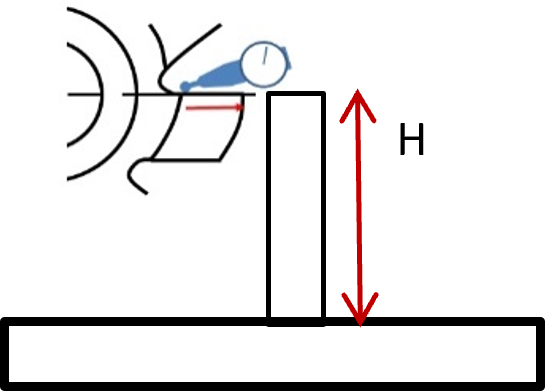

H = B-(A/2) - 3.Assemble the gauge blocks to level the height as same as the center point(Note 1).

- 4.Set the tester probe up on the top face of blocks and adjust the dial as 0.

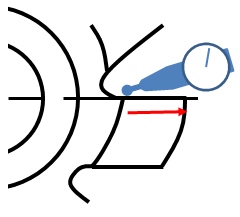

- 5.Move the tester probe near the bottom of the hob cutting face and rotate the hob until the tester indicates “0”. (Do not adjust the tester)

- 6.Move the probe to the tip side and read the dial.

- In case of the raked cutting face, adust the block height as below

- Block height = Mandrell center point / H - Offset length