Cutting Tool News

Effective hob shift length

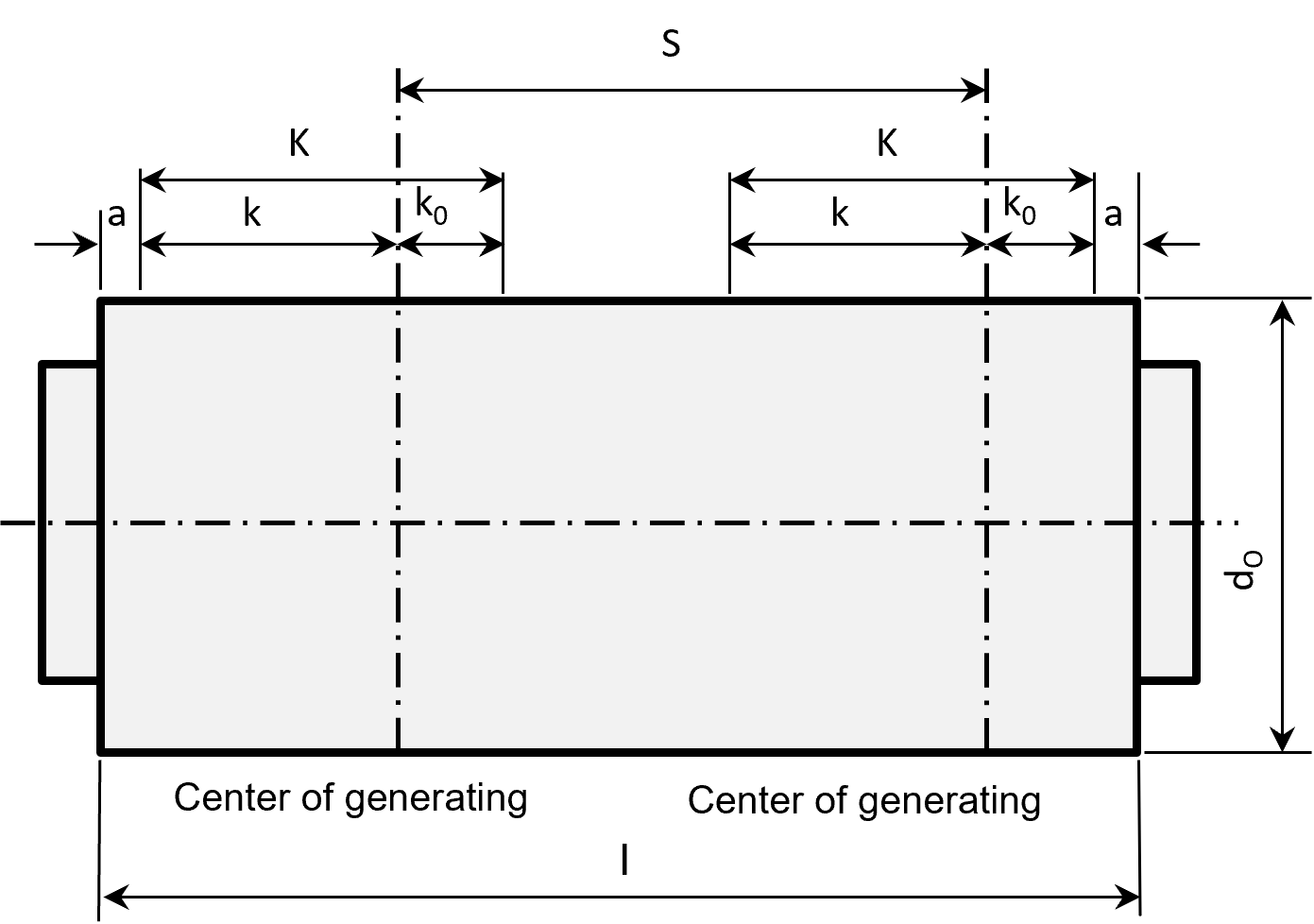

For better tool life, the hob shift length should be set appropriately to use all effective teeth and maintain tooth wear uniformed. These days, the hob shift length is automatically calculated by NC hob machine's program. Here, we introduce the calculation fomula as well as the graph to calculate the effective shift length.

- S Effective shift length = I-(K+2a)

- K Effective tooth length = k+ko

- k = see FIG.2. as below

- ko = Ca * cosβ / tan(αn) * cos(τ)

- a (allowance) ≒ π / 2 * module

- Ca : Hob tooth addendum

- αn : pressure angle (normal)

- β : Helix angle of cut part

- τ : hob setting angle

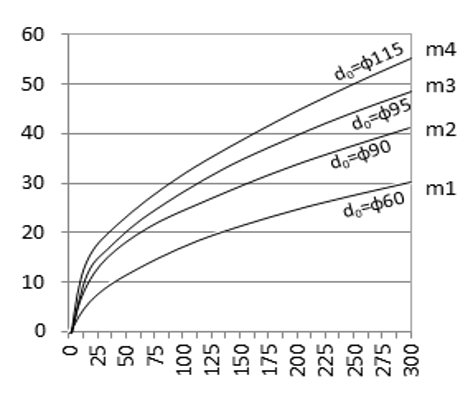

Effective hob tooth length at tip diameter varies depending on the gear dimensions as in diameter, helix angle and the hob dimensions as in outer diameter, lead angle, and also the hob cutting method.

Fig. 2 shows a calculation chart of the effective tooth length in case of climb cutting with the the 2 starts hob for the helical gear (HA30 °).

- (Exercise)

- Part dimensions :

module2.25 PA14.5 NT25 β・30° D0 70 - Hob dimensions :

do 90, 2 starts, tooth length 130 - Calculation

- k = 23 k0 = 13

- K = 23 + 13 = 36 a = 3.5

- S = 130 - ( 36 + 7 ) = 87 (mm)

k / Effective hob tooth length at tip diameter in Climb

Cut of Helical Gear ( HA 30°) / In case of 2 starts hob