【 Eccentricity of broaching hole against pre broaching hole】

Trouble shooting for internal broaching

During broaching, the broach is in an unstable state only supported by the puller.

As a result, cutting forces become unbalanced due to various factors, causing the broach to move in the direction of lower cutting forces.

The following phenomena occur in the workpiece broached in this state,

- When the outer circumference is processed by holding with broaching hole, the unprocessed surface remains.

- Go-gauge doesn't go thru the broaching hole.

- Tooth profile is not formed properly.

- The bias of in between pin diameter increases.

- In case of the broach with round teeth, uncut minor diameter surface remains partly.

- In case of the broach without round teeth, minor diameter is broached partly.

How to examine the cause of eccentricity

STEP 1 : Easy check-up

- Instruction

- In order to hold locating position of workpiece and broach at every broaching process,

- A) Mark workpiece before broaching and mount it at the same direction every cycle.

- B) Mount the broach with the certain position at circumference of front shaft, for example by marking, to set as the starting point.

- C) Broach some workpieces by rotating the broach mounting position every 90 degrees and do it with 4 positions from 0 to 270 degrees.

- D) Determine the maximum run-out position of the workpiece.

- Probable cause based on the result

| Eccentric direction | Cause |

|---|---|

| Same direction as workpiece mark | Broaching machine |

| Direction moves with the broach position. | Broach |

| There are variations in the eccentric directions (In case None of above is applicable.) | workpiece |

STEP 2 : Further investigation

For problems caused by broaching machine

- 1.Broaching machine needs maintenance

- Is the face plate horizontal? (Vertical broaching machine)

- Use the test bar to check if the puller and the traveling direction are perpendicular to the face plate.

- Are the sliding surfaces not damaged?

- Is there unnecessary clearance?

- 2.Uneven coolant fluid flushing

- Change the outlet nozzle of flushing tube.

- Flush the coolant over the entire circumference and length of the blade.

For problems caused by broach

- 1.Unevenness of tooth tip diameter circumference

- check up the tooth tips by magnifier if the tips are not worn abnormally or the chips are adhered.

- Inspect run-out of the cutting face angle at axis direction and circumference direction.

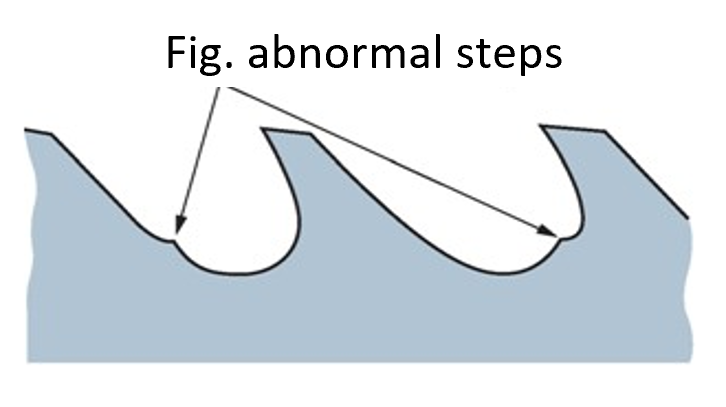

- 2.Unconformity of chip pocket shape

- Check up the chip pockets shape if it has been occurred abnormal steps by resharpening process.

- 3.Bent of broach tool

- Check up the run-out of tooth tip diameter circumference of front, middle and back against centring holes by dial gauge.

- Broach bending has little effect on eccentricity in case the length of the workpiece cutting length is short.

For problems caused by workpiece

- 1.Accuracy of pre broaching hole

- Check up roundness, cylindricity, perpendicularity of pre broaching hole to reference face.

- The clearance between the front guide diameter of the broach and the workpiece hole diameter should be within 0.03 mm.

- 2.Uneven metal composition

- Inspect metal composition, or check up hardness of workpiece several areas by hardness tester.