Nidec's 150 kW E-Axle model (Ni150Ex) has made its way into another car in GAC NE's lineup of electric vehicles. The new EV—the third model in GAC NE's Aion series—driven by Nidec's traction motor system was launched recently in June this year and goes by the name Aion V.

GAC New Energy Automobile Co., Ltd. (GAC NE) is a brand established in 2017 that manufactures electric vehicles under the umbrella of China’s GAC Group. The company has been investing actively since the beginning; in December 2018 they opened a new EV plant with a production capacity of 200,000 units per year. GAC NE has grown rapidly and secured a prominent position in the market as evident by the fact that the first car in the Aion series—Aion S—has constantly ranked among the best-selling electric vehicles in China since its launch in May, 2019.

The newly launched Aion V—the third model in the Aion series—is based on GAC NE's aluminum EV platform GEP2.0. The car incorporates a number of new technologies such as 5G connectivity, automatic parking and level 3 autonomous driving based on high-accuracy maps.

Nidec's Ni150Ex E-Axle (maximum power output: 150 kW, maximum system torque output: 3,900 Nm) that powers the Aion V has been adopted by 6 different electric vehicle models1 so far. By leveraging know-how—built up with small precision motors in the IT field—related to magnetic circuit design and by using permanent magnets and a proprietary oil-cooling-based design, Nidec has developed a compact motor that, combined with the 2nd generation of our inverter, contributes significantly to the excellent vehicle performance, low power-consumption, low noise and vibration and light weight of the car.

In addition, a new Nidec-developed PBW (Park By Wire) system will be used for the first time by some versions of the Aion V. PBW is a variant of SBW (Shift By Wire) that controls the parking pawl and locks the transmission using an electrical signal instead of a mechanical connection when the shift lever is placed in the park position. The system operates at the right time by using an electronic control unit connected to the PBW actuator to assess the driving conditions of the vehicle, making for a system that is compatible with future advancements in autonomous driving. The PBW system, the traction motor system and the electric oil pump that drives the cooling and lubrication systems are integrated into a single module (referred to as a “power pack” by Nidec) and all use in-house motors controlled by electronic control units.

GAC NE's Aion series (all models are driven by Nidec's E-Axles)

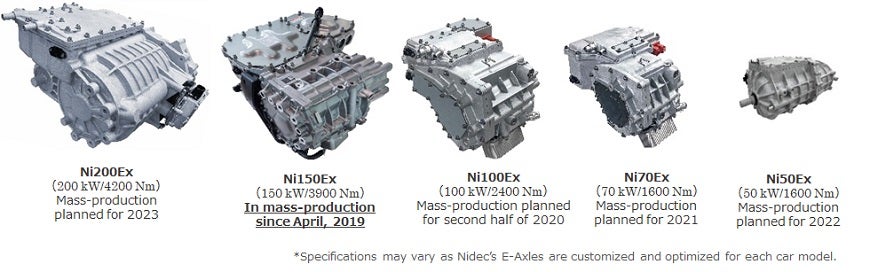

Nidec's E-Axle traction motor system lineup

Nidec's E-Axles are characterized by being compact and light-weight as a result of their fully integrated designs that combine motors, inverters and gears. In addition to the Ni150Ex 150 kW model that became the first fully integrated traction motor system of its kind in the world designed by a supplier to enter mass-production in April 2019, Nidec has also developed four other models: Ni200Ex (200 kW), Ni100Ex (100 kW), Ni70Ex (70 kW) and Ni50Ex (50 kW). Furthermore, cars that use a front + rear dual motor configuration can be supplied with up to 400 kW by combining two Nidec E-Axles. Armed with this world-class comprehensive lineup, Nidec is capable of supplying traction motor systems that can power an estimated 98% of all electric passenger vehicles. Nidec has set a target of achieving 35% global market share in the EV traction motor market by 2030.

1Cars driven by Nidec's E-Axles (as of July 1, 2020)

1.GAC New Energy Automobile, Aion S

2.GAC Toyota Motor, iA5

3.GAC New Energy Automobile, Aion LX

4.GAC NIO New Energy Automobile Technology, HYCAN 007

5.Geely Automobile, Geometry C

6.GAC New Energy Automobile, Aion V

Nidec was founded in Kyoto, Japan in 1973 by four engineers and has since grown into a world-leading comprehensive motor manufacturer encompassing more than 300 subsidiaries employing over 120 000 people throughout the world.

After becoming the first company in the world to successfully commercialize a direct drive spindle motor for HDDs using brushless DC motor technology, the company branched off into the automotive motor market which now constitutes its fastest growing business segment. Nidec’s electric power steering motors, in particular, have captured the largest global market share and helped cement the company’s position in the industry.