- Nidec Tosok Corporation

- Noboru Kankeo (Representative Director and President)

- 2-24-1 Sobudai, Zama City, Kanagawa, 252-8570, Japan

Nidec Tosok Corporation (“Nidec Tosok”) announced today that it has launched space-saving visual inspection equipment for beverage production lines.

A “visual inspection” is a process for manufacturing company to check the surface of a product to maintain and monitor its quality or that of its components. At present, many manufacturing sites use human visual inspectors to perform such inspections, causing various issues including how to secure people, train them, establish common standards, reduce workload, and ensure traceability.

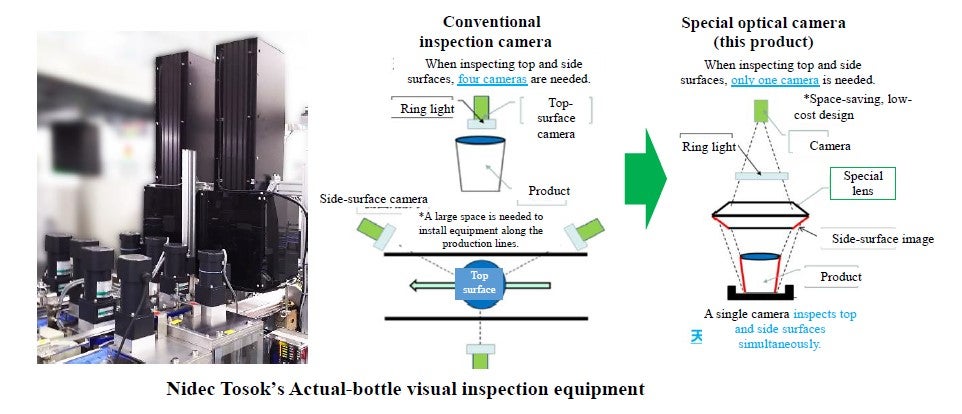

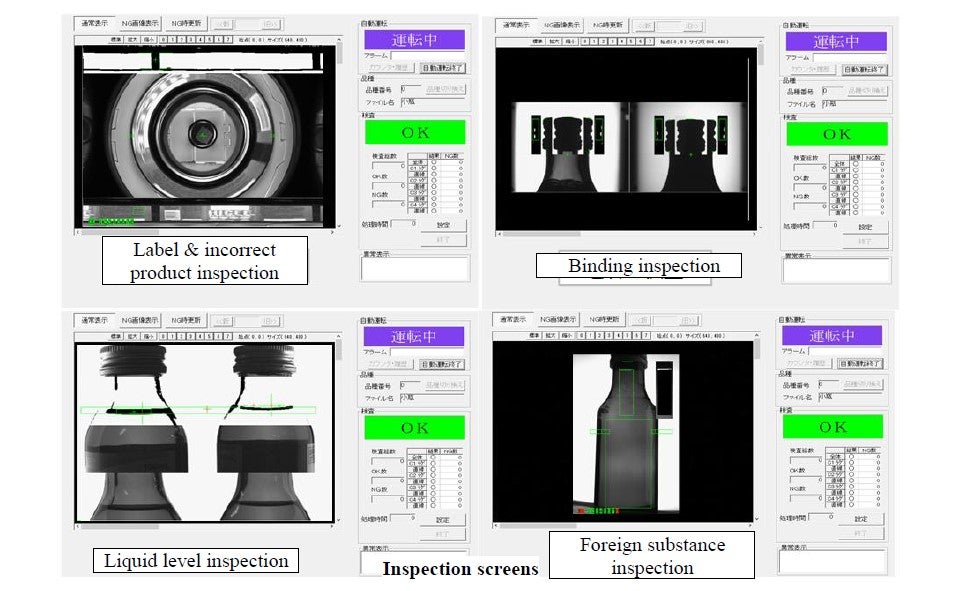

Nidec Tosok’s latest actual-bottle visual inspection equipment boasts a consolidated function of inspecting or searching for (i) units of different kinds, (ii) binding, (iii) labels, (iv) liquid levels, and (v) foreign substances in the liquid.

In general, an inspection line uses a different set of equipment for each process. With Nidec Tosok’s latest inspection equipment, all of those processes can be combined as one, eliminating space for the lines. In addition, with a special lens adopted for the inspection camera to meet our customers’ needs, top and side surfaces can be inspected with the single camera.

Nidec Tosok stays committed to seeking measurement and high-precision processing technologies, and proposing, at an overwhelming speed, revolutionary solutions that contribute to the evolution of industry.

For inquiries on the above product, please contact Sales Group of Nidec Tosok’s Sales Divison 3 (Tel.: +81-46-252-3132).

On April 1, 2023, Nidec Tosok Corporation will be renamed Nidec Power Train Systems Corporation.