NIDEC's Technical Capabilities

The Advanced CAE Technology behind our Optimally Designed Modules and Units

Shorter Development Times With Coupled Analysis and Other Optimization Tools

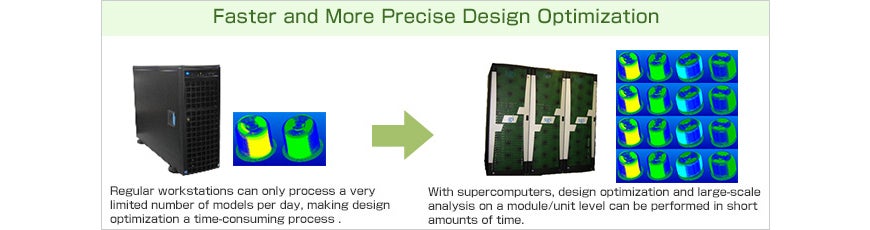

Modules and integrated units combining motors with fans, blowers, pumps and various other mechanical components—as opposed to simple stand-alone motors—are becoming an integral part of Nidec's business and they often play a central role in the solutions we suggest and supply to our customers. Aiding us in designing these advanced integrated products is the vast power of computer-aided engineering. Supercomputers, in particular, have proven to be incredibly useful tools for speeding up the design process of high-precision integrated modules/units by making large-scale and coupled analysis possible.

With their superior computational speed, supercomputers are unparalleled tools for product design. Tapping into their vast potential allows for the verification of more models in less time and lets us arrive at optimal designs in an expedited manner. Moreover, they also allow us to visualize microscopic phenomena, making it possible to utilize high-precision coupled analysis to locate and eliminate noise sources among other things. This technology is put to use in our development centers outside of Japan as well, with the aim of bolstering the scope and speed of Nidec's design capabilities on a global scale.

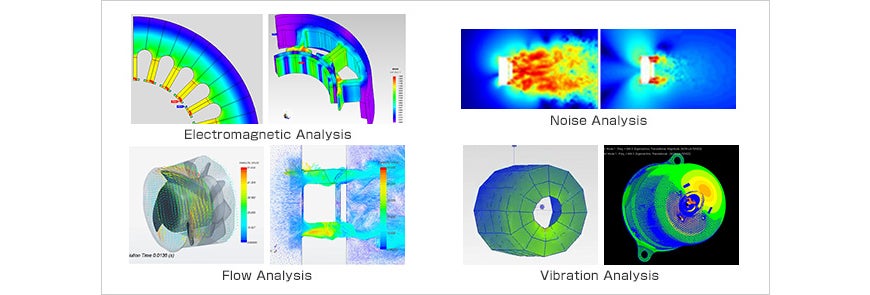

As the industry moves from stand-alone components to complex modules and units, the capacity to analyze the interaction of different physical phenomena becomes necessary. For example, in the case of a cooling fan blowing air towards an object being cooled, multiple factors related to e.g. heat, fluid dynamics, structure and sound—by how many degrees is the object being cooled? Is the interaction between the air and the surrounding structure generating any noise? If noise is present, what is the nature of its frequency?—are analyzed together with coupled analysis technology. Armed with these capabilities, we develop products in the home appliance and automotive fields that fulfill the needs of our customers: quietness and low vibration.

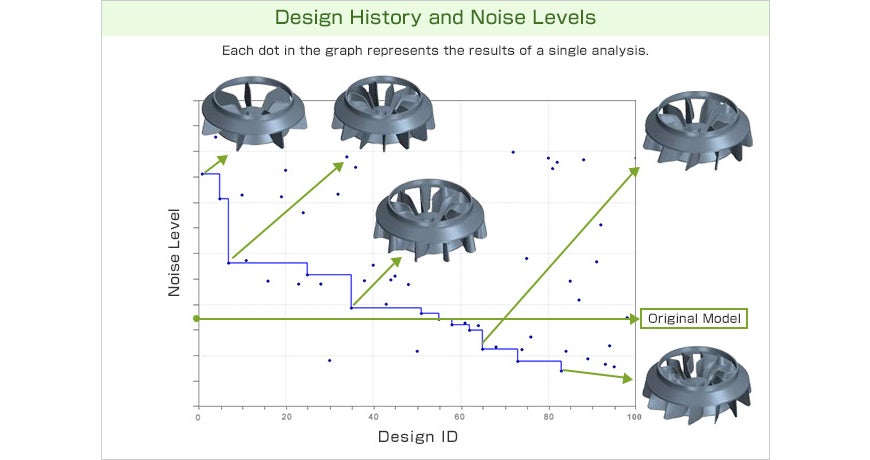

Automatic optimization is another potent technique used to rationalize the design process. This approach can be used to, for instance, automatically combine and evaluate various patterns of variables for a cooling fan—such as the number, dimensions and shape of the fan blades—in order to determine the correct specifications for achieving a desired balance of airflow and noise. In this way, we utilize optimization algorithms to automate a process that, up until now, has depended largely on the experience and intuition of the designing engineers. In the future, we plan to further expand the scope of this method to include factors such as yield rate and mass-producibility to determine the best specifications from a comprehensive standpoint.

As automobiles, home appliances and various other products used in our daily lives become automated and equipped with motors, demand for products that are even more effective, quiet and less prone to vibration is expected to rise. At Nidec, we believe that supercomputers and computer-aided engineering are the keys to developing newer better products that meet these needs.