Future Technologies

E-Axle, Nidec’s Traction Motor System (EV Drive Motor System)

Nidec Became the World’s First Company to Mass-produce E-Axle, the Key to EVs’ Diffusion.

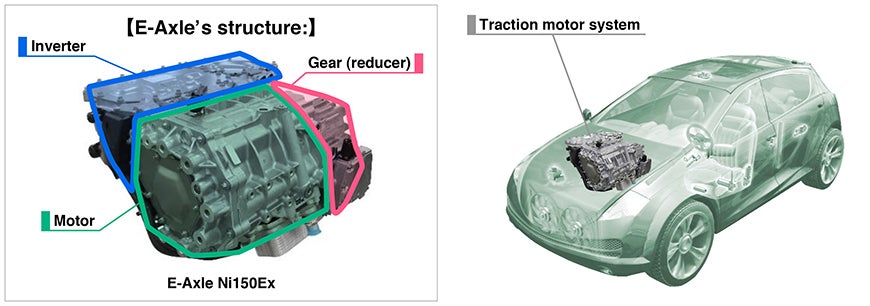

The traction motor system, the heart of the electric vehicle (EV) that comprises a motor, an inverter, and a reducer, generates rotating torque when installed in a car and connected to its drive shaft. This product alone is enough to run a vehicle.

Since 2019, Nidec has been serving as the world’s forerunner in mass-producing the traction motor system, E-Axle. 300,000 units were produced as of March 2021, and a total of 700,000 units have been produced as of April 2023.

Nurturing Technologies to Make Compact, Light Products

Amid the increasing awareness of global climate issues, the EV market is continuing its rapid growth. In an extremely harsh competitive environment, speed is the indispensable lifeline for auto manufacturers in EV development. E-Axle, the product that combines an inverter and a motor, can help auto makers to develop their models more quickly than before.

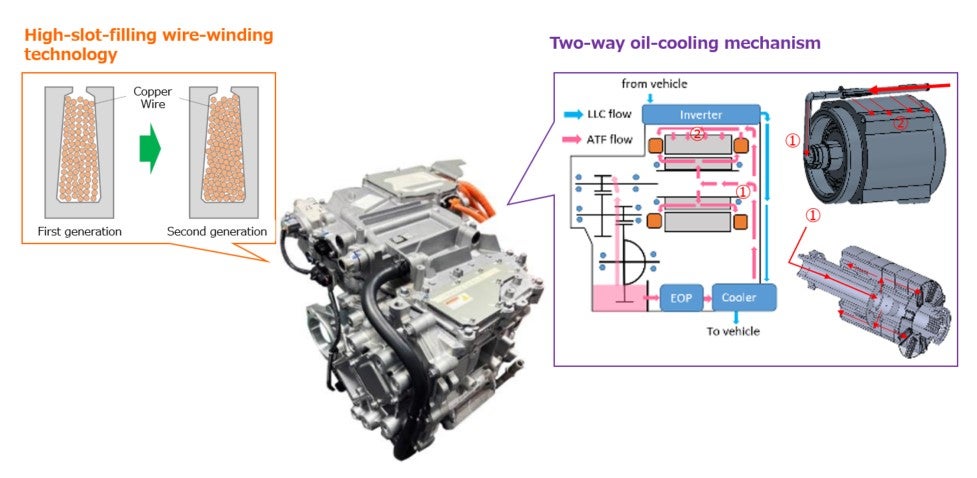

E-Axle is required to generate sufficient output and be efficient based on the volume of the output; be compact and light, highly reliable; and be versatile enough to work in various types of vehicles. Paramount among these features is “compact and light,” as it is directly linked to the car’s “electricity efficiency.” Over numbers of years, Nidec has been nurturing technologies to make super-small and -thin products especially in the IT industry. It was by utilizing such product development-related knowhow for E-Axle hat Nidec successfully produced an industry-leading traction motor system.

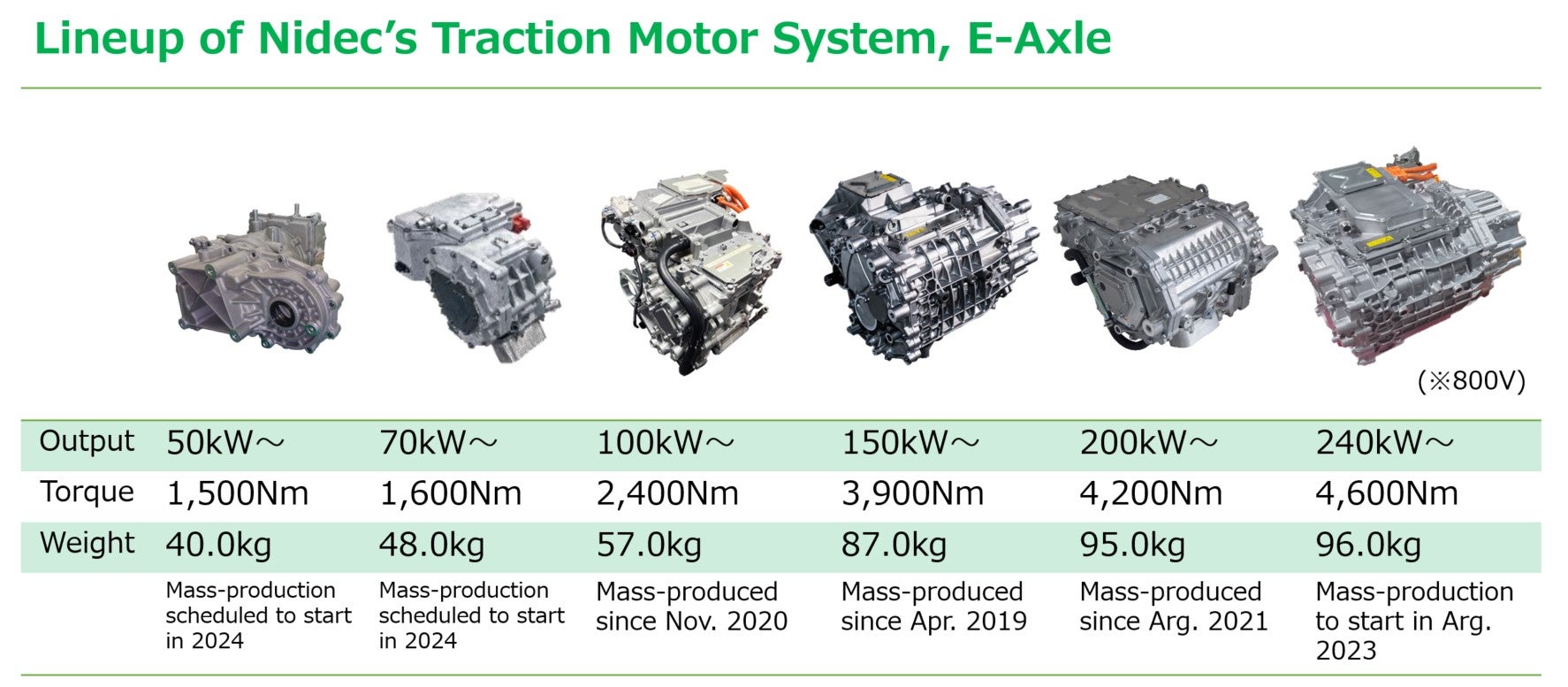

A compact and light product, which is highly kinematic, powerful, electricity-efficient, and quiet, possesses a great flexibility in body designing. The second-generation model of E-Axle, which Nidec started mass-producing in October 2022, boasts an output of 135kW, a toque of 2,400Nm, and a weight of merely 57kg, and far exceeds other companies’ similar products in power density. Such advantages caused Nidec’s E-Axle to garner support in China, the country leading the world in the diffusion of EVs, and the products has been adopted in 15 models as of April 2023.

Aiming to achieve a 45% global market share in 2030

With six types of E-Axle with different outputs available, Nidec’s E-Axle units are installed in various types of cars, ranging from compact to high-end ones.

Going forward, EVs are expected to be used by an even larger number of people, and people are believed to own 300 to 600 million EVs globally in 2030.※ Nidec targets to achieve a global market share of 40 – 45% with its E-Axle in 2030. Toward this goal, we will accelerate our R&D activities to quickly build traction motor mass-production systems all over the world.

※Global EV Outlook 2022 IEA 2022.5

https://iea.blob.core.windows.net/assets/ad8fb04c-4f75-42fc-973a-6e54c8a4449a/GlobalElectricVehicleOutlook2022.pdf

Know More about E-Axle

Second generation of E-Axle

Further development of the Heart of the EV.Compact, Light, and High-power Traction Motor

E-Axle: Its Strengths

Consistent system to handle everything from development to production