E-Axle: Its Strengths

Consistent system to handle everything from development to production

For the Full-scale popularization of EVs

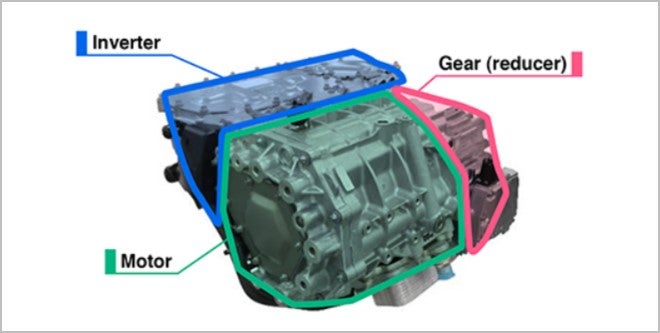

The demand for E-Axle, Nidec’s traction motor, is on increase toward full-scale popularization of EVs, which is expected to start in 2025. A key component to replace the gasoline engine, the E-Axle is being a subject of a growing number of requests regarding efficiency to improve torque characteristics and drive distance, quietness, reduction in size and weight, reliability, ease of maintaining, and many others on features that affect EVs’ performance and ride quality.

Completing Everything In-house: From Development to Production

Simply combining a motor, an inverter, and a reducer would not make an E-Axle. One must develop and assemble as many as 400, complex components respectively, and optimize them as a single system.

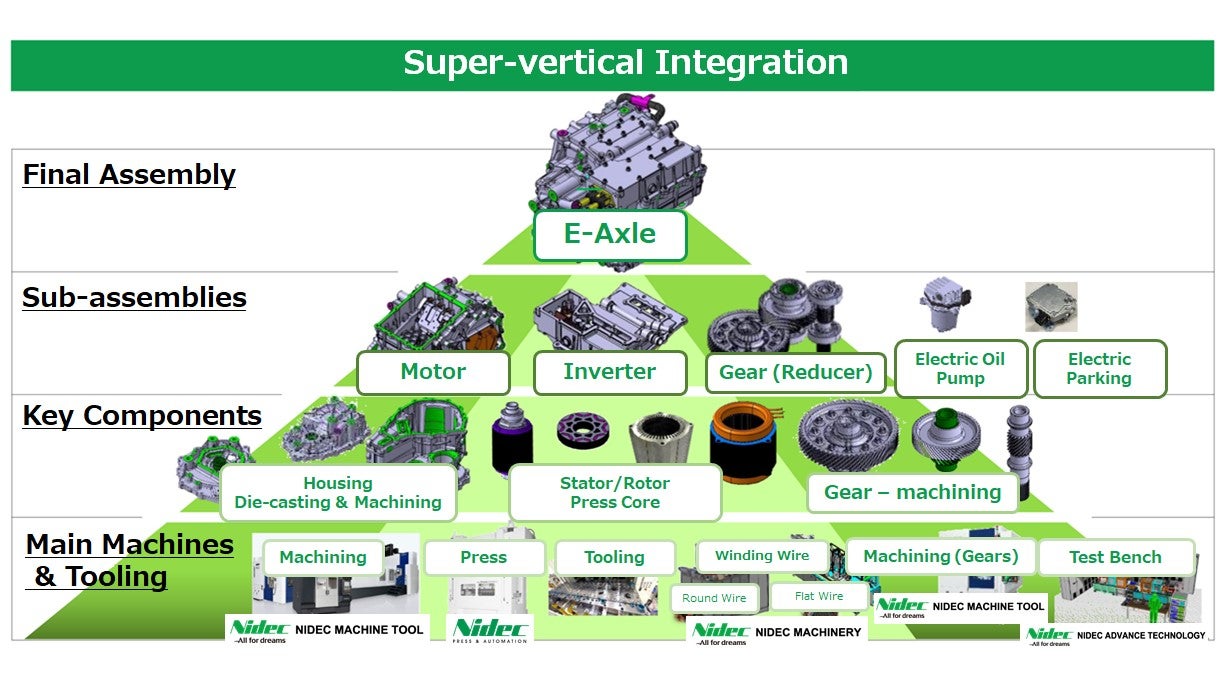

The Nidec Group can complete all such processes of the E-Axle, ranging from E-Axle development to production, in-house. That is, we produce in-house not only the traction motor’s key components, but production and testing equipment for such components as well, in what we call the “super-vertical integration.” This is how we secure the excellent quality, shorten the lead time, and reduce the costs of our products.

Fast Product Development to Meet the Market’s Needs

Nidec’s another strength is its speed to develop products. In general, the process of developing designs, producing, and supplying E-Axle units is said to require two to two-and-a-half years, but Nidec was able to finish this entire process in one to one-and-a-half years. This is thanks to the aforementioned super-vertical integration to shorten our lead time, combined with making E-Axle platforms to develop derivative models easily. Such a design concept that we has in mind since the product development phase proved effective. Not only has this production system enabled us to accommodate the needs for all vehicle segments ranging from compact cars to large SUVs, it also gives us the ability to develop fast E-Axle units based on respective models’ characteristics.

Striving to Obtain the Largest Global Market Share

Thus, Nidec is taking all steps necessary as it steadily prepares to develop and produce products that meet the market’s needs. We are poised to expand our production capacity and develop new products more quickly than before, as we advance to occupy the world’s largest market share in the traction motor business.

Know More about E-Axle

E-Axle, Nidec’s Traction Motor System

(EV Drive Motor System)

Nidec Became the World’s First Company to Mass-produce E-Axle, the Key to EVs’ Diffusion.

Second generation of E-Axle

Further development of the Heart of the EV.Compact, Light, and High-power Traction Motor