Future Technologies

IoT (The Internet of Things)

The Age of Big Data—When Everything Becomes Interconnected—Has Arrived; Motors, the Backbone of Industry, Contribute Toward an Affluent Society

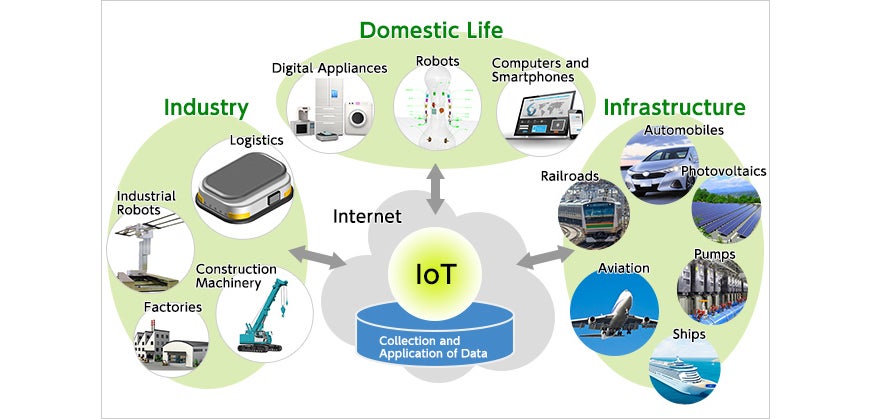

Up until now, the internet has mainly been used to connect computers, tablets and other devices that require human input. However, recent advances in technology have decreased the cost of microprocessors and telecommunication modules, allowing previously unconnected “things” to tap into the internet and start communicating and transmitting information. These “things”, as referred to in the context of IoT, can constitute a wide variety of objects such as production equipment used in factories, everyday home appliances, automobiles or even vending machines found on street corners.

By interconnecting these devices through common networks, machine to machine communication, without any human input, can be realized, allowing for operating state reports, warning alerts, restocking requests and other orders to be exchanged and handled automatically.

In addition to being processed in real-time, information exchanged via machine to machine communication can also be stored as big data and analyzed to provide feedback useful for the formulation of operation and production plans and the design and development of new products. In this respect, motors—the backbone of the 21st century industry used for production equipment as well as in everyday life applications—will assume a crucial role in the coming age of IoT not only as actuators but also as sensors generating the data sets that constitute big data.

In recent years, a global trend of adopting IoT for manufacturing applications in a bid to improve productivity and allow for flexible low-volume production of a wide variety of goods has emerged with Germany as one of the leading actors. The German “Industry 4.0” project was born as a public-private joint initiative to revolutionize the industry by creating a network-based automated smart system encompassing the entire supply chain including the manufacturing process, logistics and vendors. This system not only provides capabilities to respond to low-volume production of large varieties of goods but also opens the door to mass customization—production of individually customized products at the same price as mass produced goods.

“Industry 4.0” and similar initiatives aimed at dramatically increasing manufacturing and infrastructure performance are gaining momentum not only in Germany but around the world as well. In response to this global trend, Nidec is actively seeking to create new solutions combining its hardware capabilities—centered on motors, motor-based modules, robots and other manufacturing and inspection equipment supplied and used around the world—with big data analysis functions and other software making use of IoT.

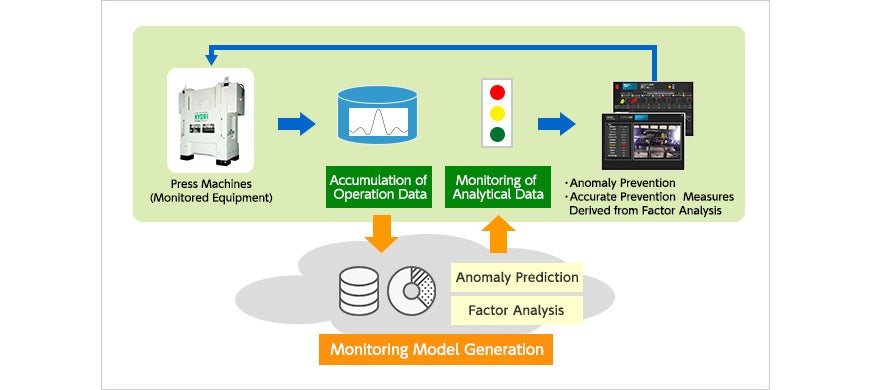

One example of the application of this technology can be seen in our factories where press machines are being equipped with a variety of data collecting sensors working together as a system. By analyzing how the data of each individual sensor correlates to the information gathered by the other sensors, symptoms of anomalies can be detected in advance, preventing breakdowns before they happen. In the future, we seek to further expand this technology into the realm of machine to machine communication with manufacturing equipment that can make adjustments to improve product quality based on information provided by inspection equipment one step further in the manufacturing process, creating a self-adjusting feedback loop functioning without human input.

Nidec commands a significant share of the global market for motors—the backbone of industry supporting the infrastructure of our society. Utilizing big data based on these motors opens up a multitude of new possibilities. For example, operational data collected from manufacturing equipment and logistics robots can be used to improve manufacturing efficiency, while hybrid and electric vehicles with data gathering capabilities allow for traffic congestion-related data to be gathered and analyzed. By promoting the emergence of IoT, the Nidec group aims to further contribute to increasing the efficiency of the infrastructure of our society.