Special Feature 2014 - Nidec's Contributions as the World's No. 1 Comprehensive Motor Manufacture

1. Solving the World Power Shortage

Taking on Challenges

Nidec Contributes to Energy Saving and Energy Creation

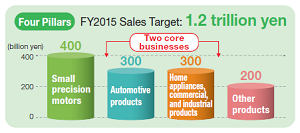

In each of the four pillars that represent its core business fields (small precision motors; automotive products; home appliances, commercial, and industrialproducts; and other products), the Nidec Group offers high-efficiency motors and related products, while furthermore entering into the power generation business to help save and create more energy.

Electric Motors Consume Approximately Half of Electricity Generated Over the World

As newly emerging economies and other countries consume power at an explosively rapid pace, securing oil and other sources to generate power is becoming increasingly difficult, and the world now faces a serious power shortage. The amount of power consumed by motors is believed to be 40–50% of total power used in the world (55% in Japan),※1 and the spread of high-efficiency motors is essential in solving the power shortage. A movement has already been initiated in Europe and the U.S. to restrict the sale of motors which fail to meet the IE2※2 (high efficiency) and IE3※2 (premium efficiency) international standards. Japan too has decided to introduce a “Top Runner” system to ensure the compliance of industrial motor efficiency to the IE3 standard from 2015, in preparation for the promotion of nationwide adoption of high-efficiency, energy-saving motors.

※1 Source: The Japan Electrical Manufacturers’ Association, “Top Runner Motor”

※2 Standard set by the IEC (International Electrotechnical Commission)

Widespread Adoption of High-efficiency and Energy-saving Products Decreases World CO₂ Emissions, and Leads Us Away From Fossil Fuels

“Vision 2015” for areas of higher demand

The Nidec Group aims to contribute to solving the world power shortage and reducing CO2 emissions through its business activities. In our mid-term business management target, “Vision 2015,” we are striving to expand our business based on self-sustaining growth and M&A, with a focus on the automotive, home appliance, commercial, and industrial sectors, where motors are required in particular to be highly efficient and energy-saving.

Encouraging the Spread of High-efficiency Industrial and Home Appliance Motors

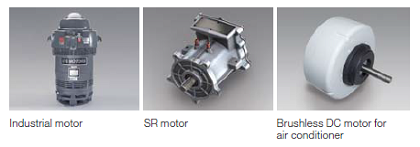

〈 Industrial and SR motors 〉

The power consumed by industrial motors is estimated to be approximately 66% of that annually consumed by motors in Japan.※1 Despite this large power consumption rate, almost all industrial motors used in Japan currently operate at the IE1 (standard efficiency) level. Preliminary calculations suggest that IE3 (premium efficiency)-level motors represent an annual saving of as much as 7%※1 per motor, which would be a significant contribution to energy-saving efforts. The U.S. has in place the world’s strictest standard—NEMA※2 (equivalent to the IE3 level)—and Nidec has sold NEMA premium motors for industrial applications, which meet this standard, since 2011.

Furthermore, Nidec has been working to develop switched reluctance (SR) motors that achieve a higher level of efficiency. SR motors are highly energy-efficient and have a simple yet robust structure. This demand is increasing in large heavy construction equipment, such as excavators, and agricultural machinery. Nidec intends to encourage the spread of both IE3-compliant motors and SR motors across the world, and help reduce industrial power consumption.

※1 Source: The Japan Electrical Manufacturers’ Association, “Top Runner Motor”

※2 NEMA: The National Electrical Manufacturers Association

〈 Brushless DC motors for home appliances and air conditioners 〉

Suppressing the level of peak power usage is equally important in reducing total power consumption. In Japan, the power consumed by air conditioners exceeds 50% of total household power consumption during the summer season (July–September), when the country’s aggregate electricity demand peaks.※

In Japan, where highly energy-saving inverter air conditioners are already used in almost all households, brushless DC motors are essential in achieving even higher levels of efficiency. Currently, Nidec’s brushless DC fan motors are used in approximately half of inverter air conditioners in Japan and are also increasing their presence in the global air conditioner market, the majority of which is represented by major Chinese manufacturers. In countries with underdeveloped electricity infrastructure, we seek to contribute to energy savings and better living conditions by supplying high-efficiency module products combining a fan motor with a compressor. Our first step in this direction is the construction of air conditioner motor factories now underway in China and India.

※ Source: Estimate by the Agency for Natural Resources and Energy of Japan

From Energy Saving to Infrastructure Development

From Power Generation to Power Distribution:

Taking on challenges in the smart grid business

Tackling the issue of global power shortage takes more than just reducing dependence on fossil fuels; it extends to utilizing “future energies” including renewable sources, such as sunlight and wind. The Nidec Group, taking one step beyond the energy savings offered by high-efficiency motors, wishes to help solve the power shortage through the creation of electricity.

In June 2012, Italy’s Ansaldo Sistemi Industriali S.p.A. (now Nidec ASI S.p.A., “ASI” hereinafter) joined our Group. Over the past 150 years, ASI has been developing power generation, transmission, and distribution systems mainly for ships and railroad vehicles while improving its efficiency technologies. ASI is currently building solar power plants for the most part in Europe, a region advanced in the field of photovoltaic generation. ASI will continue making smart grids possible, handling all stages from generation to transmission of natural energies.