Contribution to Environment through Products and Solutions

Introduction to Products with Environment-friendly Design

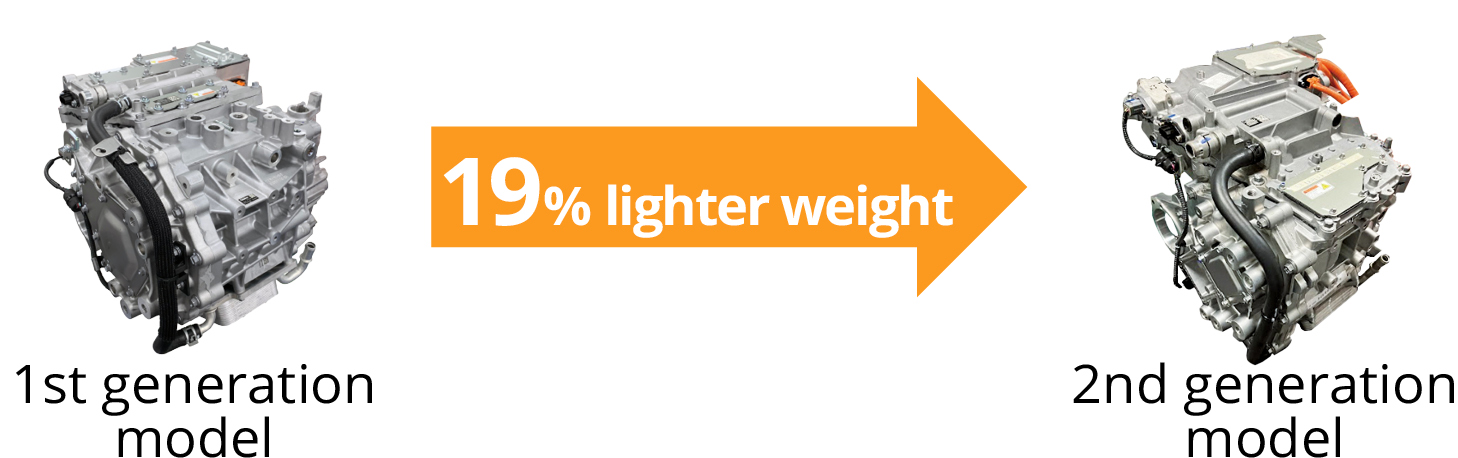

Smaller and lighter electric vehicle traction motor system "E-Axle"

The E-Axle traction motor system for electric vehicles is a product that can be said to be the heart of an automobile, replacing conventional engines. The 2nd generation "E-Axle" is 19% lighter than the 1st generation with the same output, achieving a significant reduction in materials. We will continue to promote the development of resource-saving products by making our products smaller and lighter.

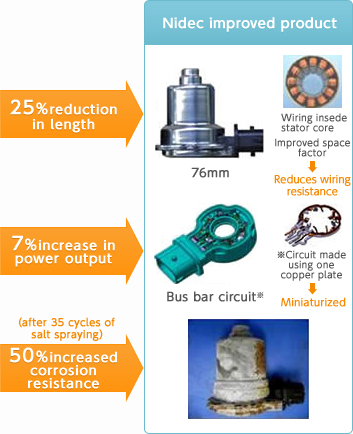

Development of Compact, High-output, and High-rust Resistant Dual Clutch Transmission Motor

Dual clutch transmission motors for automotive gear boxes have a function to shift gears instantaneously by alternately changing to either one of the two clutches.

Reduction of Resin Usage and Waste for Disposal during Molding of Automotive Motor Parts

In the injection molding process used for plastic products, resin material flows to the product molding section through a passage called the runner inside the metal mold. The molded resin is then cooled to form a product. During this process, not only the product but the resin material itself in the runner is also cooled while connected to the product. Therefore, resin in the runner section has to be separated from the product. Thus, the key to the reducing usage of resin material and waste generation during the injection molding process lies with an optimal layout arrangement of the product molding section within the mold, and the improvement of the regeneration rate for the resin in the runner section. Die & Mold Engineering Department in (Kyoto) Japan and Nidec Automotive Motor (Zhejiang) Corporation are together grappling with how to reduce usage of resin material and waste during the resin molding process used for automotive motor parts.

Development of Thinner 2.5-Inch HDD Motors

In the field of IT, we are promoting development of HDD as storage devices for handheld terminals and home information appliances based on the key words "space saving", "lightweight", and "low price." Nidec's 2.5-inch HDD motor is now produced with a thinner thickness of 7 mm in comparison with the conventional mainstream thickness of 9.5 mm, along with a motor cubage saving of approximately 30%, and a motor that is approximately 13% lighter. This has made it possible to install HDDs in tablet PCs and thin notebook PCs, which also helps reduce resource use.