E/Environment

Contribution to Environment through Products and Solutions

The Nidec Group provides motor-driven products and solutions specializing in "everything that spins and moves," centered on a diverse motor business ranging from precision small to ultra-large units. Through our business activities, we strive to provide solutions to global challenges and fulfill our mission to "Contribute to the world by producing the highest-performance motors in the world."

The Nidec Group’s Manufacturing Strengths

It is said that about half of the electric power generated in the world is consumed by motors. Currently, most of these motors are low-efficiency motors such as AC motors and brushed DC motors. Seeking to produce more efficient and sophisticated motors, and by demonstrating our high-level manufacturing capability of lighter, thinner, shorter, and smaller products, the Nidec Group is poised to develop and provide products and solutions that contribute to reducing society’s environmental load by, for example, reducing electricity consumption and materials to use. We also provide solutions that support the spread of renewable energy, and play a role in global energy conservation and decarbonization.

Contribution to society and the environment through low-carbon and decarbonized products

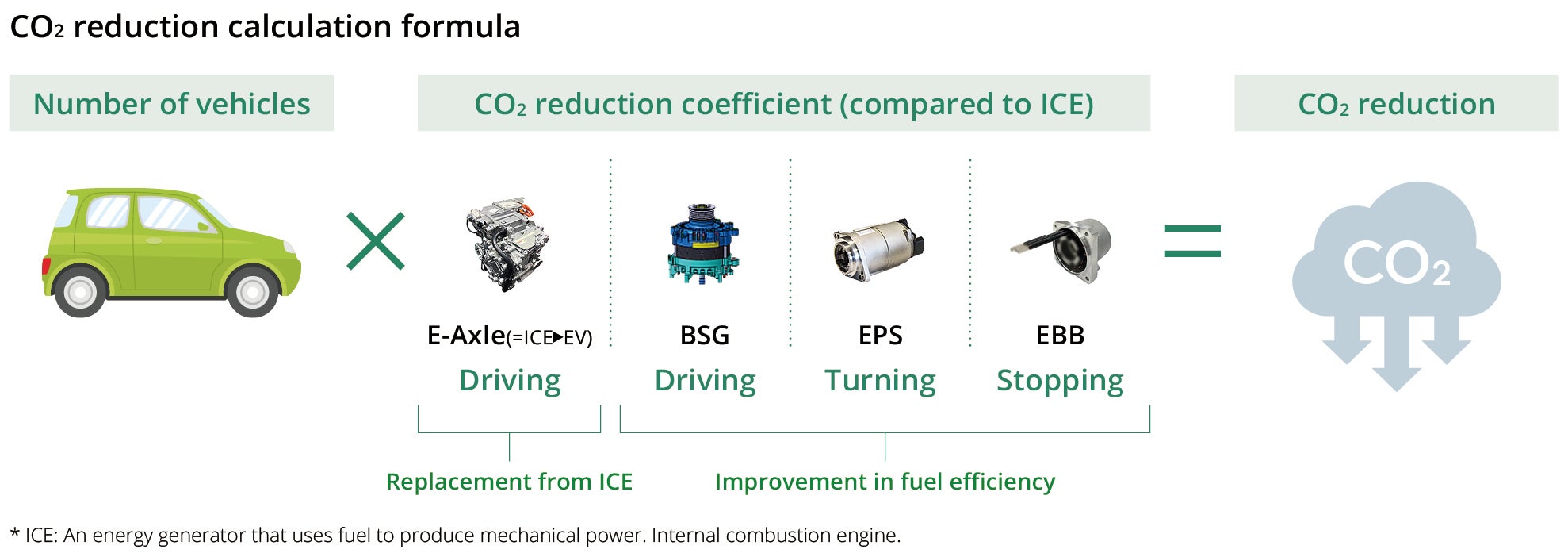

In providing the world with products that contribute to society and the environment, the most important thing is the basic design of the product. In addition to our ongoing efforts such as increasing energy efficiency to help customers save energy when using our company’s product, and using less materials by making lighter, thinner, shorter, and smaller products, other factors such as using less energy for product manufacturing and selecting more low-carbon materials are important as well. So far, Nidec has had in place a system to quantify, as the “amount of avoided emissions*1,” the effect of CO₂ emissions reduction during the use phase of EV traction motor system E-Axle and other automotive motors.In addition to the system, for other phases of lifecycle as well, we used the Life Cycle Assessment (LCA)*2 to build a carbonization-based environmental impact assessment method, and started quantifying individual lifecycle phases’ CO₂ emissions. Establishing an environmental impact assessment method enables us to quantify the “amount of our reduction contribution” in a comparison of our conventional products, and to launch actions for further CO₂ emissions reduction. We will utilize our strengths such as highly energy-efficient products and the capability to make lighter, thinner, shorter, and smaller products, to reduce our products CO₂ emissions.

※1 "avoided emissions" at the stage of use of automotive motors is quantitative targets are disclosed in materiality initiatives. For more information about materiality initiatives, please click here.

※2 Life Cycle Assessment (LCA) is a method to quantitatively assess potential environmental impacts on the earth and ecosystems during the life cycle of a product, from procurement of raw materials to disposal or recycling.

Target and Achievement

In its Seventh Mid-term Environmental Conservation Plan, the Nidec Group aims to promote the development and dissemination of ecofriendly products in line with the product-based contribution to decarbonization, which we regard as a materiality theme. Specifically, to achieve our FY2025 goal, we set numerical targets for “contributions from our automotive business” and “contributions from our small precision motor business,” promoting actions to achieve the targets.

Seventh Mid-term Environmental Conservation Plan and Materiality

- The Seventh Mid-term Environmental Conservation Plan: Environmental Contribution through Products “Promote the development and dissemination of products that contribute to the environment”

- Materiality: Contribute to environmental sustainability “Contribute to decarbonization through products”

| KPI (FY2025) | FY2024s result | |

|---|---|---|

| Contributing through Automotive Products | Reduce CO₂ emissions by introducing the EV traction motor system (E-Axle/BSG): Cumulative total from FY2020 to FY2025: 11,700,000 t-CO₂ | 18,010,000 t-CO₂(total) |

| Reduce CO₂ emissions by introducing electric power steering (EPS-PP/EPS) motors: Cumulative total from FY2020 to FY2025: 26,261,000 t-CO₂ | ||

| Reduce CO₂ emissions by introducing electronic brake booster (EBB) motors: Cumulative total from FY2024 to FY2025: 10,029,000 t-CO₂ | ||

| Contributing through the small precision motors | Reduce CO₂ emissions by introducing motors for compact EVs: 35,000 t-CO₂ per year | 6,600 t-CO₂ |

| Reduce CO₂ emissions by introducing motors for e-bikes: 32,000 t-CO₂ per year | ||

Actions

In our society, energy continuously converts from one form to another: from motive power to heat, from heat to electricity, and from electricity back to motive power. Through our products and technologies, the Nidec Group will contribute to the realization of a sustainable, Circular Society in which energy is converted with high efficiency.

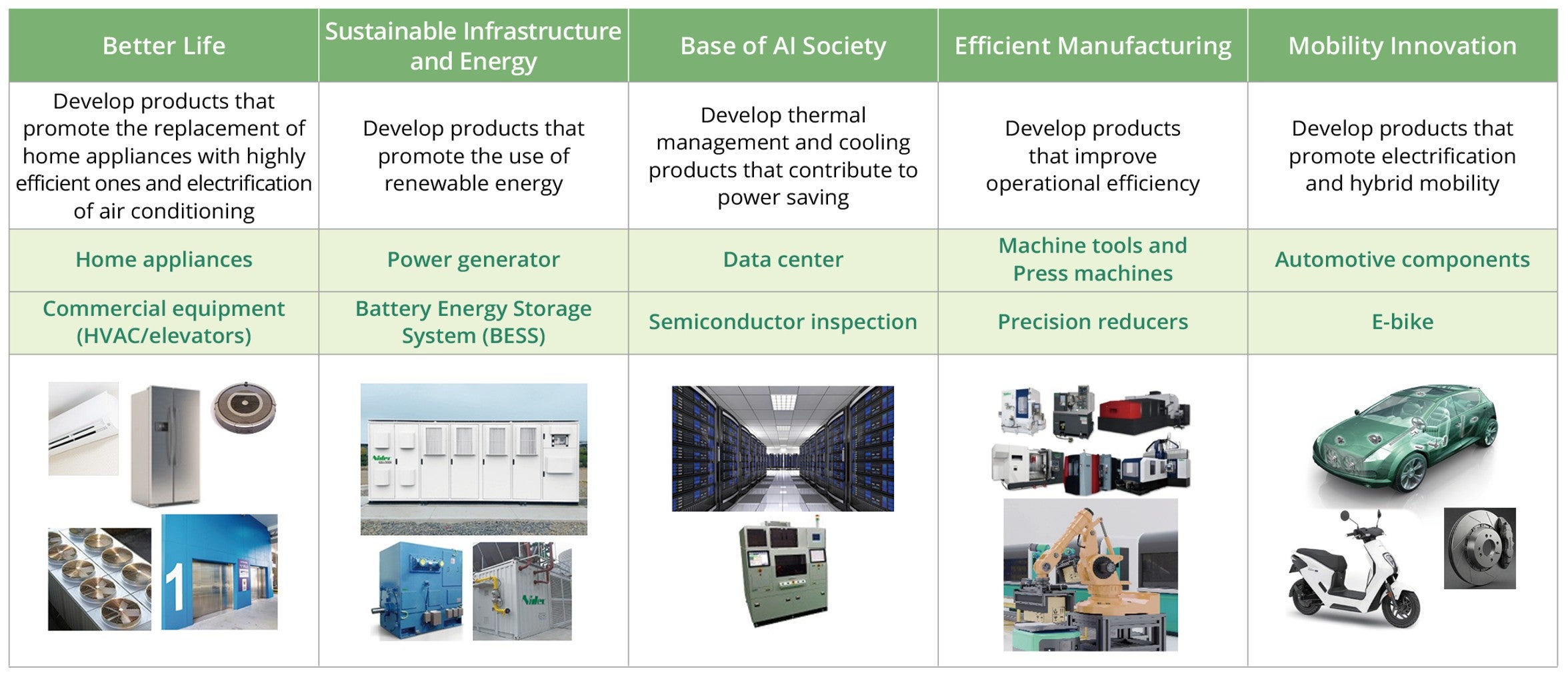

<Five Business Pillars to Support the Future Growth>

There are five key business areas of the NIDEC Group that are particularly important for a sustainable, Circular Society in which clean energy is circulated smoothly. We intend to expand our business by designating these five key businesses as strategic focus areas. Our focus spans from AI-related fields where cutting-edge technologies converge, to home appliances integral to daily life, as well as large-scale social infrastructure and mobility.

① Base of AI Society

This pillar includes thermal management components such as water-cooling modules and fan motors for AI datacenters, and motors for HDDs, which are data-recording devices. The high-efficiency thermal management technology is essential for datacenters, whose cooling equipment accounts for 31% of an entire system’s electricity consumption.

・Overview

With the emergence of 5G environment and generative AI, data traffic and the number of data centers are increasing rapidly. Additionally, the revolution in semiconductor technology is growing the density of CPU and GPU units, neither of which can be sufficiently cooled with air-cooling fans anymore. This trend necessitates the direct-chip cooling technology that uses water-cooling modules.

・Effects

Water-cooling modules, which can cool mechanical devices significantly more efficiently than air-cooling systems, can reduce an entire server operation system’s air-conditioning load by 20 – 30%. In addition, partially due to the expected increase in the amount of heat generation caused by high-density microprocessors, water-cooling modules can curb an entire datacenter’s electricity consumption and help datacenters use less electricity, serving as an essential solution to support the future 5G/6G society.

・Examples

- ‒ Thermal solutions

- ‒ Coolant Distribution Units to respond to growing thermal loads

- ‒ Air-cooling fan that respond to thermal migration in a datacenter

- ‒ UltraFlo Fluid Dynamic Bearing Fans for Thin Laptop Computers

② Sustainable Infrastructure and Energy

To supply renewable-energy-derived electricity efficiently, the Nidec Group offers its innovative battery storage technology and electricity management technology, promoting the prevention of power supply disruptions and the introduction of renewable energies.

・Overview

With energy conversion sector emitting the largest amount of CO₂ in the world, it is important to promote the introduction of renewable energies to suppress greenhouse gas (GHG) emissions. The technology for large-scale electricity-storing systems to supplement unstable electricity generation is crucial in promoting the introduction of renewable energies. The Nidec Group produces Battery Energy Storage Systems (BESS) units that use power management technology, enabling the stable supply of electricity.

・Effects

Nidec utilizes its revolutionary storage battery and power management technologies to support the introduction of renewable energies and contributes to minimizing greenhouse gas emissions. Used in 27 countries and regions around the world, Nidec’s BESS units boast a total operation capacity of 9.1GWh.

・Examples

③ Efficient Manufacturing

In addition to various machine tools for a diversity of industrial fields, the Nidec Group can propose solutions based on different machining needs and production processes. Utilizing "everything that spins and moves," we help realize labor saving, automation, high speed, and high precision in manufacturing.

・Overview

Due to the decline in the working population, labor shortages in all industries have become a social issue, and the need for labor-saving and automation through the introduction of robots and mechanical equipment is rapidly increasing as a solution. In addition, work that depends on individual skills and requires a high degree of accuracy is being replaced with high-precision machines to improve labor productivity. We offer a full line of products in this field, including reducers, press machines, and machine tools.

・Effects

The vertical lathe is equipment capable of heavy-duty cutting and high-precision and stable machining. Vertical lathes can process heavy and complex-shaped workpieces – both of which are difficult to support or balance with a horizontal lathe. Due to its structure, a vertical lathe has a feeding Z axis in the direction of gravitational force, constantly generating load on the servo motor simply for the lathe to maintain its position. Nidec’s vertical lathes are energy-efficient as they use a system that switches their servo motor off while in a standby mode to maintain the position of the lathe with its motor-equipped brake and to curb energy consumption. This mechanism has successfully reduced the entire machine’s standby electricity usage by 16% from Nidec’s conventional models.

・Examples

④ Pursuing a Better Life

Motors are said to consume approximately half of the world’s electricity. By utilizing its long-nurtured technology, the Nidec Group develops high-efficiency motors and contributes to curbing global electricity consumption.

・Overview

The Nidec Group offers a variety of motors of different sizes – from small precision motors to super-large ones – and motor-applied products and services in IT equipment, office automation equipment, home appliance, automobile, commercial and industrial equipment, environmental and energy, and so many other industries. Nidec’s high-performance motors, which pursue lighter, thinner, shorter, and smaller as technologically possible, are used widely in our daily lives.

・Effects

Among Nidec’s motors, the high-efficiency, IE5-compliant 7.5kW synchronous reluctance motor can save 1500kWh of energy in its annual operation of 7,000 hours. Unlike permanent-magnet motors, this synchronous reluctance motor does not use rare-earth metals, and is gaining attention as a solution to protect resources and for addressing supply instability.

・Examples

- ‒ Compact and light brushless DC motor for cordless vacuum cleaners

- ‒ Motor For Cleaning Robot

- ‒ Resin-Packed Motors

- ‒ Solutions for glass elevators

⑤ Mobility Innovation

The transportation sector is believed to account for 21% of the global CO₂ emissions, with approximately 75% of the 21% estimated to be originated in automobiles. The Nidec Group is poised to adopt its drive motors to four- and two-wheel and aviation fields to contribute to the world’s decarbonization efforts by electrifying mobility products.

・Overview

To curb transportation-originated CO₂ emissions, the Nidec Group introduces its high-efficiency motors to transportation options that have been dependent on internal combustion for their various inputs, and promotes the electrification of mobility products. One of Nidec’s main products for electric vehicles (EVs) is E-Axle, a three-component (a motor, a gear, and a inverter) traction motor system that works as an EV’s heart. Nidec also boasts a large lineup of products to meet the needs for low output and high voltage.

・Effects

The next-generation E-Axle, which applies the Nidec Group’s technologies to make lighter, thinner, shorter, and smaller products, is 35% smaller than its first-generation model, and boasts light weight, high output, and space efficiency. Small E-Axle units help us to use less resource, as the reduction in the use of minerals contributes to the global CO₂ emissions reduction (4 – 7%). With the use of a magnet-free induction motor, and a simple structure and robustness characteristic of induction motors, we aim to improve our motors’ rotation, while adopting multiple technologies to develop small, light, high-output, high-density, and high-efficiency products.