Implemented Solutions

Compact and high-precision power steering (EPS) motors

This compact and high-precision power steering motor, which can be retracted in a limited space, helps people to drive safely and comfortably.

- NEEDS

- Make a well-designed automobile with a smooth steering capability.

- SOLUTION

- Considering how the motor will be produced, redesign it from scratch, and generate cogging torque.

Reduce the variance to one-tenth of what it used to be, while reducing the cogging torque, to approximately halve the product’s size.

Significantly reduce the cogging torque, an unavoidable issue for motors, to secure a smooth steering.

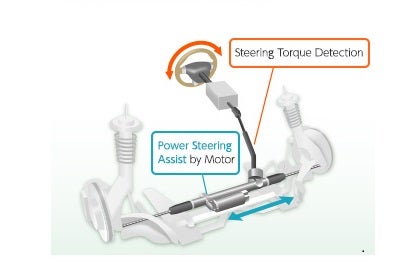

The power steering unit assists drivers with steering their automobiles. After replacing the once-general hydraulic unit, the motor-driven electric unit is now mainstream, making the power steering (EPS) motor an essential automotive component.

Nidec has been supplying EPS motor units since 2003. With its products highly evaluated for their sizes, which are compact enough for the units to be installed in an engine room’s limited space, and for their smooth operational feeling, Nidec has established itself as the market leader.

Smooth assisting is regarded as important in EPS units. An inconsistent assisting would hurt the operational feeling, and cause the driver to feel uncomfortable, while making his/her steering technique inaccurate. With the hydraulic unit, the power enhanced by the mechanism is transmitted directly to the shaft, while, with an EPS unit, the motor needs to start rotating as the driver starts to turn the car’s steering wheel, whose speed must be detected and controlled.

The biggest challenge was to reduce cogging, which is a rough, resisting force created when a motor shaft is rotated with a finger, caused by the action of the rotor’s teeth and the permanent magnet.

Cogging, which occurs when the motor is not energized, is unavoidable so long as a magnet is used. Still, many drivers feel uncomfortable at the subtle “clicking-like” pulsation that is generated when the motor starts to apply power to the steering unit, causing lingering criticism that the hydraulic power steering system is far better than the EPS one.

Nidec’s EPS motor units, which meet the needs for compact size, better heat resistance performance, and mass-production, lead the market

On the other hand, making a compact EPS motor unit has consistently been the most critical issue for the past 20 years. Components and units are concentrated around a fuel-engine vehicle’s steering unit, making the size of space for individual components very limited. At Nidec, we have successfully reduced the size of our EPS motor units by 10 – 20% at every transition from 2003’s first generation through the current and fourth generation (as of 2021), making the latest model less than half the size of the first one.

Our EPS motor units’ heat resistance performance has improved significantly as well. While the first-generation model was installed inside the vehicle interior, the second-generation model and its successors were placed into the steering rack beneath the engine, which is close to the car’s exhaust pipe, etc., and exposed to a severe thermal environment. This change increased the heat resistance requirement from 85ºC to 140ºC. To meet this requirement, Nidec had a comprehensive review of its magnets’ composition and orientation to successfully develop EPS motor units that perform stably even under a harsh heat environment.

In addition to these element technologies, we launched other actions such as simplifying designs to the best extent possible to sophisticate our mass-production technology and successfully reduce our prices, to meet the market’s expectations.