Implemented Solutions

Development of Ceiling Fans and Outlook for the Future

ODM Services Focusing on Ceiling Fan Components, Units and Ready-to-Use Products—Starting with the Indian Market and Aiming for Global Expansion

Ceiling fans play an important role in the cooling of households and make up an enormous market in India. In order to secure our position in this market, we have expanded our capabilities to meet the diverse needs of our customers with a wide range of solutions—including both ready-to-use products (as an ODM supplier) and modules/units centered on brushless DC motors combined with electronic controllers, blades, remote controllers and more. In addition to being smaller, lighter, more efficient and having better controllability than their conventional AC counterparts, the brushless DC motors used in our ceiling fans, and related products, are also attracting attention for their stable performance allowing them to maintain constant rotational speeds even under the unstable voltage conditions inherent in the Indian market.

Officially, the voltage in India is said to be 230 V. However, in reality the number fluctuates heavily between 140-280 V. Moreover, in contrast with ceiling fans for the Japanese market—used as circulators with low rotational speeds between 100-200 RPM—ceiling fans for the Indian market, designed for direct cooling, have blades as long as 1.2 m rotating at 300-400 RPM. As a result, ceiling fans used in India are comparatively more sensitive to voltage drops, further contributing to the problem of voltage fluctuation.

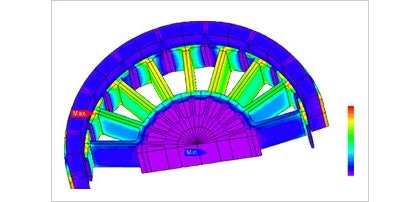

Brushless DC motors, with their many advantages over AC motors, are generally more expensive as well. In order to overcome this problem and answer the demand for inexpensive products, we optimized the magnetic circuits using magnetic field analysis and reduced the size and thickness of the motor core. The result was a more cost effective design capable of producing the same amount of torque using less material. Moreover, by integrating the back yoke of the magnet with the motor housing and improving the very construction of the motor, we managed to further reduce costs while freeing up the surface of the motor—increasing freedom of design—in the process.

At Nidec, we strive to offer solutions to customers to help them produce ceiling fans using our latest energy-efficient motors.

Developer's Comment

One major challenge in developing these products was how to maintain our motors’ characteristics in the products in order to achieve the customer-requested rotational frequency and airflow in a limited amount of time.

On the other hand, the use of a structure that allows flexibility on the products’ surface enabled us to develop motor units whose surface can be finished the way our customers requested us to.

Going forward, we aim to utilize our technological capabilities to create even better products, and introduce ceiling fans using brushless DC motors into the global market to contribute to building a sustainable society.