Implemented Solutions

Integrated units for hair dryers combining brushless DC motors with AC-DC power supply circuits

By Replacing Universal Motors with Nidec's Brushless DC Motors,

Hair Dryers can be Made Significantly Smaller and Lighter

- NEEDS

- Smaller and lighter hair dryers

- SOLUTION

- Downsized brushless DC motors with integrated AC-DC power supply circuits

Hair Dryers Equipped with Universal Motors are Large, Heavy and Prone to Vibration

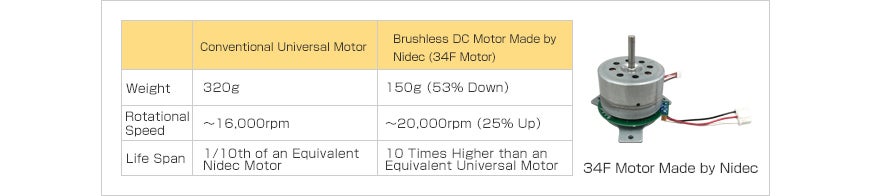

Conventional hair dryers traditionally make use of AC universal motors capable of achieving high-speed rotation while operating on single-phase power supplies commonly used in households. However, as the industry is witnessing a shift towards smaller, lighter and more power-efficient appliances, the need for a transition to brushless DC motors—the mainstay of Nidec's business—has become increasingly evident. In response to this trend, Nidec has started supplying brushless DC motors with integrated AC-DC power supply circuits to the major hair dryer manufacturers. These integrated units, weighing less than half of their conventional AC motor counterparts and being substantially smaller in size, have contributed significantly to making hair dryers easier to handle, which in turn has garnered praise for decreasing the risk of developing tenosynovitis: an occupational disease common in hairdressers.

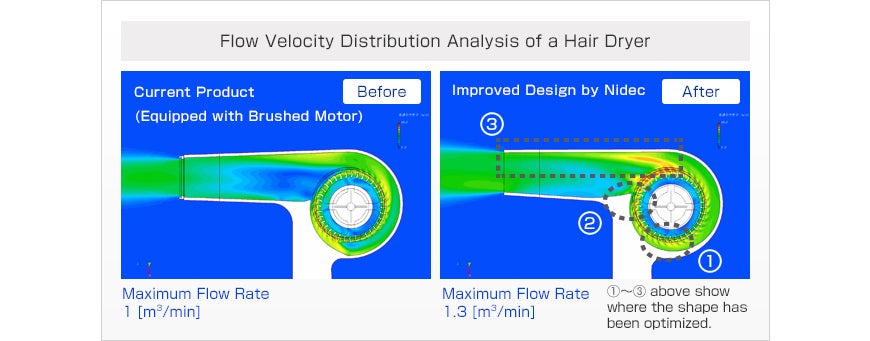

Contributing to the Hair Dryers of the Future with our Advanced Fan Design Technology

In addition to the brushless DC motors with integrated power supply circuits that we currently supply, Nidec also possesses advanced technology for designing fans and blowers. In particular, our capabilities include innovative technology for flow analysis, thermal analysis, acoustic and vibration analysis—the core processes of fan and blower design. We have a wealth of experience in using supercomputer simulations to develop unique fan blades that dramatically improve the performance of end products such as refrigerators and electric fans in the appliance and IT fields. Using this expertise, we aim to further contribute to improving the performance of hair dryers by creating and designing even more precise and advanced fan modules capable of maintaining the same airflow at lower rotational speeds, leading to reduced noise and vibration.