Implemented Solutions

UltraFlo Fluid Dynamic Bearing Fans for Thin Laptop Computers

Smaller and Thinner Fan Motors Made Possible with Fluid Dynamic Bearing Technology Originally Developed for Hard Disk Drives

- NEEDS

- Smaller, thinner and quieter fan motors for thin laptop computers

- SOLUTION

- FDB (Fluid Dynamic Bearing) technology optimized for fan motors coupled with noise reducing and air flow maximizing design based on flow analysis

Leveraging our Expertise in the HDD Field to Optimize FDB Technology for Fan Motors

As the areal density of HDDs increases, they become more and more susceptible to external vibration. At the same time, the rotational speed of server cooling fans is being driven up by extra heat generated by increasing CPU clock speeds, resulting in the appearance of fans rotating as fast as 20,000 rpm. These factors combined led our customers to request a solution to the problem of HDD read/write performance being affected by the vibration of fans mounted in servers. Our answer was born from the idea to utilize FDBs (Fluid Dynamic Bearings)—originally introduced by Nidec as a replacement for ball bearings to reduce vibration in HDD spindle motors—for fan motors as well.

Recent performance increases in thin laptops have led to increasingly higher CPU clock speeds. As a result of this trend, heat dissipation has become a major problem. At the same time, noise has become another concern, leading to an increase in demand for quiet fans. By leveraging the expertise built up by Nidec with our HDD spindle motors, we succeeded in creating the quiet and low-vibration UFF (UltraFlo FDB) series of fans utilizing FDB technology. Furthermore, in order to secure our position in the highly competitive market for components for thin laptops, we accelerated the development considerably, resulting in a highly competitive fine-tuned product. Every design decision made in the context of HDD spindle motors—the layout of the magnetic circuits, whether to use resin or metal components, the diameter of the shaft, etc—was reviewed with the new function in mind.

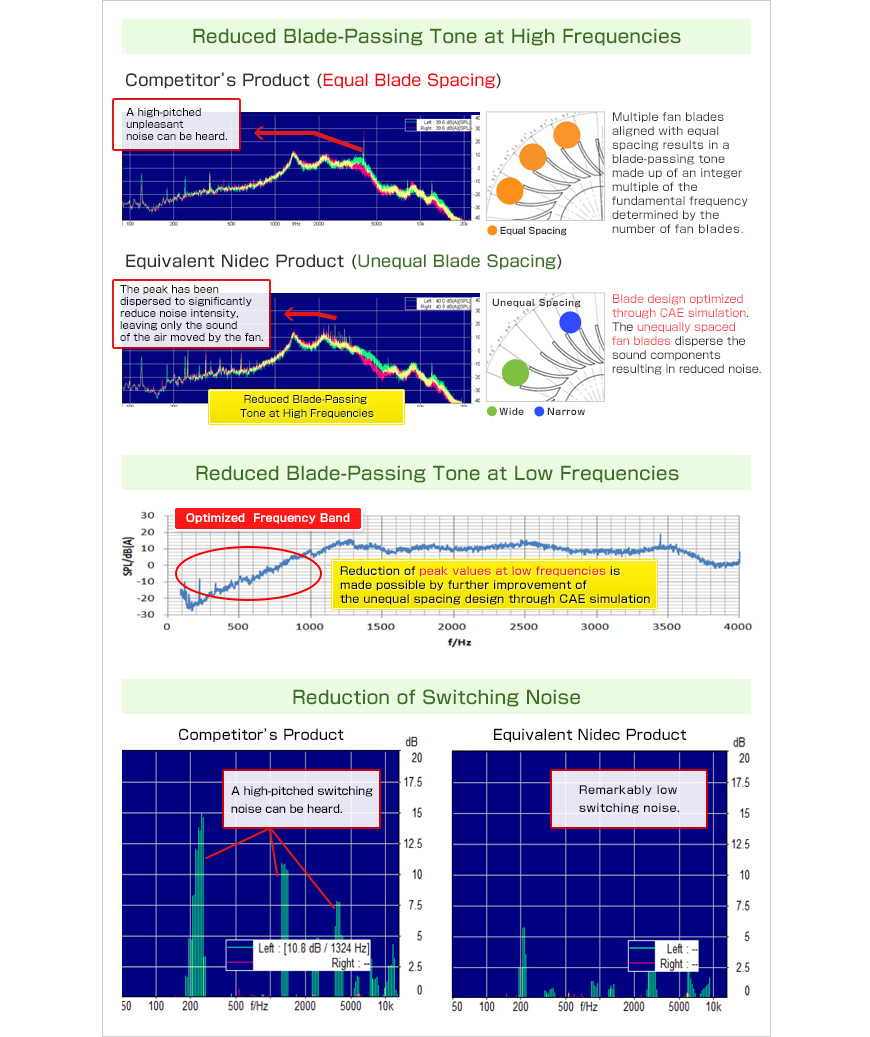

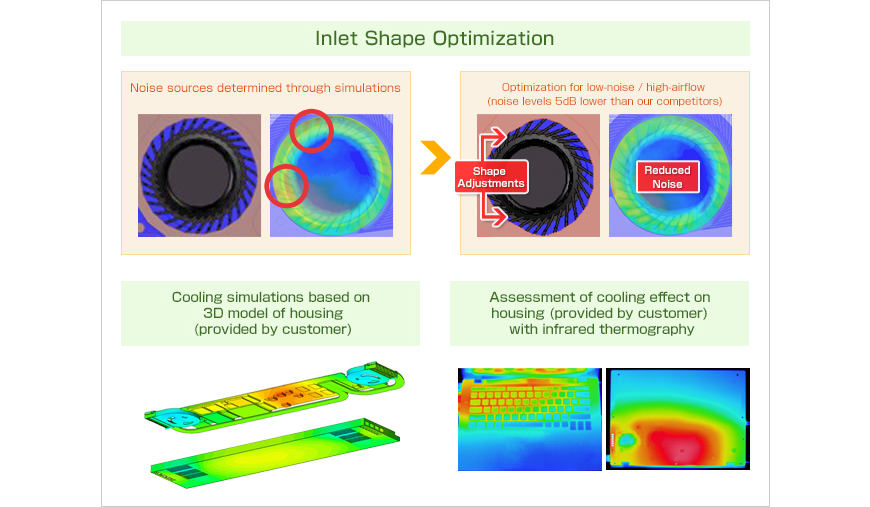

Solving Air Flow and Noise Problems with Supercomputer Aided Engineering

At the same time as we optimized the bearings and magnetic circuits, we also worked to solve the air flow and noise problems. Generally, noise generated by fan motors increases proportionally as a function of air flow. Laptops, in particular, are required to be quiet as they are used not only in offices but also in homes.

This problem was overcome by using CAE (Computer Aided Engineering) to optimize the size and shape of the fan blades for a specific air flow volume. In order to achieve this, we developed a coupled analysis technology for synthetically analyzing air flow and noise. The optimal specifications were calculated based on analysis of the relation between the path of the cool air and the noise generated. In addition to decreasing the total energy of the noise, specific frequencies were also addressed to produce a sound that is more pleasing to the human ear.