Implemented Solutions

Systems engineering for iron and steel making and finishing plants

Systems engineering for plants producing strong, smooth,

highly processable and weldable steel plates for automobiles

- NEEDS

- Design and installation of a manufacturing system to produce high quality steel strips for the automotive industry

- SOLUTION

- A processing line system that guarantees high quality through careful management of tension, pressure and speed

Extensive experience with systems engineering for iron and steel making plants

Nidec ASI has an extensive track record in providing solutions for steelworks. Our past experience in this field includes designing systems for blast furnaces, electric furnaces, steel making plants, continuous casting equipment, hot rolling, cold rolling, surface treatment, pipe production, and production of all kinds of steel in various shapes. We work closely with our customers (EPC contractors, plant makers or steel producers) starting from the idea phase of their plants and support them in all system engineering related areas such as process design, specification development, system design, hardware design, software design, manufacturing, installation, trial runs and tuning, staff training and technical support. Among the services we provide, automation platforms, software- and control algorithms, plant management- and diagnostics and motor drive systems in particular are based on advanced proprietary know how and technology, allowing us to support our customers in their mission; manufacturing high quality products that meet the high standards required in the industry at a reasonable cost.

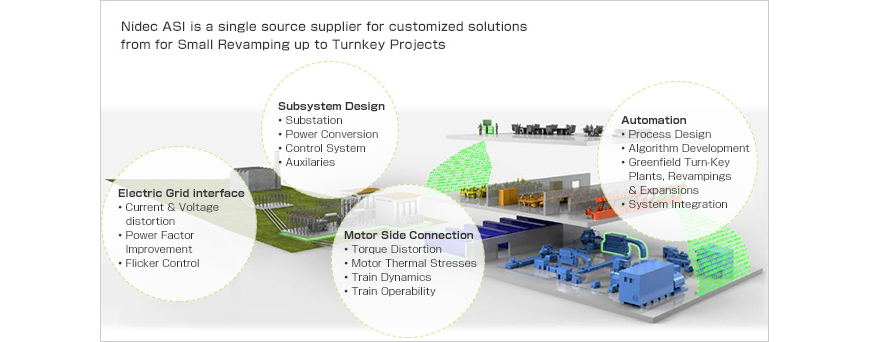

Comprehensive solutions for every step of the iron and steel making process―from small scale system alterations to large scale turnkey projects

Of all the various kinds of steel products manufactured at the ThyssenKrupp steelworks in Germany, the finished steel supplied to German automobile manufacturers, in particular, is subject to very high quality requirements. For example, steel sheets used for the bodies of automobiles are required to not only be strong, but also smooth, aesthetically pleasing and highly weldable and pressable. During the rolling process when steel sheets used for automobile bodies are made at the Galvanizing Line 8 of the ThyssenKrupp steelworks, factors such as precise tension control, speed accuracy and coordination are managed to create high quality high tensile strength steel with few internal or surface defects.

Furthermore, all parts of the process, from the entry section, the process, the skinpass up to the exit of the line are monitored and controlled precisely by our ARTICS automation system with its real time controllers and process computers. These systems provided by Nidec ASI allow for efficient production and shipment of not only steel sheets for automobile bodies but also material for the chassis, suspension, wheel disc parts, and a wide array of other applications for high quality steel sheets.