More for Society

Make Thinner Products

Being thin is a very appealing point as a component for notebook PCs. To make their chasses thin, both fans and hard disks are required to be equally thin. They each must be in a narrow space of several millimeters. Even a tiny runout of an axis will cause fans to contact the case, and make recorded data on the hard disk fragmentary and incomplete. To create motors that rotate smoothly in a space made as narrow as technologically possible, elaborate machining accuracy is indispensable. Nidec constantly seeks precision to respond to the unquenchable demand for thinner products.

Nidec’s Solutions with Thin Products

Pushing the Limits of Miniaturization with our Ultra-Thin & Ultra-Small Fans

Less than 3-mm thick and with 20-mm sides—our ultra-compact cooling fans are a result of cutting-edge design and state-of-the-art analysis and manufacturing technology.

UltraFlo Fluid Dynamic Bearing Fans for Thin Laptop Computers

Smaller and thinner fan motors made possible with Fluid Dynamic Bearing technology originally developed for Hard Disk Drives.

Image-stabilizing mechanism, TiltAC

Motors that can withstand the pressure of ocean depths of 4000m developed for submarine cable burying ROVs.

Tactile Devices

The Nidec group develops and manufactures state-of-the-art devices that revolutionize the interface between humans and machines.

Thinner HDD Motor Design

As notebook PCs become thinner, the profile of HDD motors is also becoming lower. Nidec also supports the evolution of notebook PCs by producing thinner motors.

Brushless DC Motors, Blowers and Gear Units for Vacuum Cleaners

Modules that combine the superior capabilities of brushless DC motors with blowers, gears and other components

Super-flat Actuator FLEXWAVE with Axial Flux Motor

Utilize shape-related merits to a reducer-equipped, light, thin, short, and compact actuator.

Nidec’s Technology to Create Thin Products

Fluid Dynamic Bearing (FDB) Technology

Nidec quickly began developing and manufacturing fluid dynamic bearings (FDBs), which are dramatically accelerating the increase in HDD capacity and noise reduction. We are pioneers in mass production of HDD spindle motors that use FDBs.

Submicron-Precision Machining Technology

High-precision machining technology, one of the core technologies of the Nidec group, has played an important role in our success story in the HDD motor market.

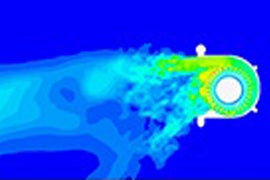

Nidec's Technical Capabilities CAE Technology Developed In-House

At Nidec, we utilize original modeling technology and analysis software developed in-house to optimize the design of our fluid dynamic bearings.

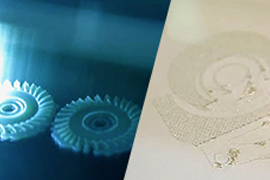

Rapid Prototyping

Exceeding the Needs of our Customers with Shorter R&D Cycles and Reduced Costs

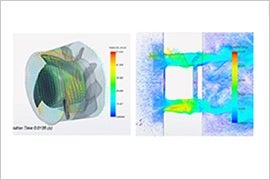

The Advanced CAE Technology behind our Optimally Designed Modules and Units

Coupled analysis and other advanced CAE tools cut down on development times and make development of advanced modules and units easier.