More for Society

Make Less-vibrating Products

Vibration occurs as a motor rotates, and becomes larger as the motor’s rotational frequency increases. Until recently, 5,000 revolutions/min. were considered sufficient for server fans; now, however, as more heat is generated after servers’ processing capacity improves, those fans are required to rotate 20,000 times per minute. At Nidec, we must accommodate the needs for faster processing and communications with larger volumes of data. To the voices for an advanced IT society, Nidec gives answers based on its persistence to accuracy that does not allow even a slight vibration or loosening, and on its revolutionary technologies that eliminate vibration.

Nidec’s Solutions with Low-vibration Products

Compact and high-precision power steering (EPS) motors

This compact and high-precision power steering motor, which can be retracted in a limited space, helps people to drive safely and comfortably.

Automated Transportation Robot Drive Module

Generate synergies within the Nidec Group to develop a high-efficiency drive module.

Helium-Filled Hard Disk Drives

HDDs filled with helium have improved read/write precision and lower power-consumption due to minimized disk vibration caused by drag.

Power Steering Motors (1st – 3rd Generations)

Nidec is developing and producing high-performance EPS motors by utilizing our motor design, control and mass production technologies that we have cultivated over the years. This is our development story of the first to third generations of power steering motors.

Integrated units for hair dryers combining brushless DC motors with AC-DC power supply circuits

By replacing universal motors with Nidec's brushless DC motors, hair dryers can be made significantly smaller and lighter.

Image-stabilizing mechanism, TiltAC

Motors that can withstand the pressure of ocean depths of 4000m developed for submarine cable burying ROVs.

Nidec’s Technology to Create Low-vibration Products

Fluid Dynamic Bearing (FDB) Technology

Nidec quickly began developing and manufacturing fluid dynamic bearings (FDBs), which are dramatically accelerating the increase in HDD capacity and noise reduction. We are pioneers in mass production of HDD spindle motors that use FDBs.

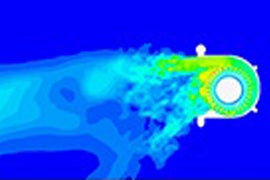

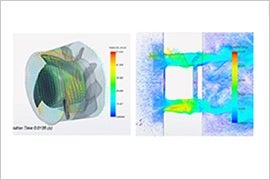

Nidec's Technical Capabilities CAE Technology Developed In-House

At Nidec, we utilize original modeling technology and analysis software developed in-house to optimize the design of our fluid dynamic bearings.

Fundamental Technology for Innovative Motors

Higher torque density, less noise and reduced vibration—laying the foundation for the motors of tomorrow

Submicron-Precision Machining Technology

High-precision machining technology, one of the core technologies of the Nidec group, has played an important role in our success story in the HDD motor market.

The Advanced CAE Technology behind our Optimally Designed Modules and Units

Coupled analysis and other advanced CAE tools cut down on development times and make development of advanced modules and units easier.

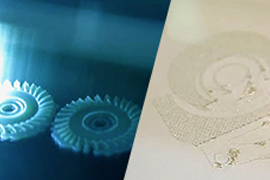

Rapid Prototyping

Exceeding the Needs of our Customers with Shorter R&D Cycles and Reduced Costs